Advancing Additive #1: Getting Control of the AM Process at a Meso Level

Editor: Welcome to the first in a series of posts we’re calling “Advancing Additive”. This series will look at key technical capabilities Siemens is developing to strengthen the end-to-end AM digital thread. Each episode will include commentary from Aaron Frankel, the Vice President of the Siemens Digital Industries Software Additive Manufacturing Program along with a short video on the technology.

Even companies with years of experience struggle with first article part quality. Successful businesses who have spent untold thousands of dollars wrestling their part quality to the ground through trial-and-error still have print failures. These companies now know their materials and their machines like the back of their hand and it still doesn’t save them from throwing scrapped prints into the recycle bin.

Unfortunately, all the knowledge they’ve gained is deep knowledge but not wide knowledge. The lessons these companies learn through thousands of prints are often only applicable to the machines and materials the company currently uses. Maybe a new material gets developed that is attractive to their customers. Maybe their vendor comes out with a new machine and a slightly upgraded process. Maybe a firmware update changes the behavior of their current machines. Then the painful learning cycle must begin again to wrestle with these new variables and to once again attain the knowledge needed to print quality parts.

What if that cycle could be short-circuited? What if the ability to print a quality part was not dependent on knowledge of a few individuals gained at great cost through failure after failure?

This is the promise of AM process simulation. The idea being that if you can simulate the printing process to a high-enough degree, then the knowledge about what works and what doesn’t is gained through a more efficient automated process rather than expensive trial-and-error.

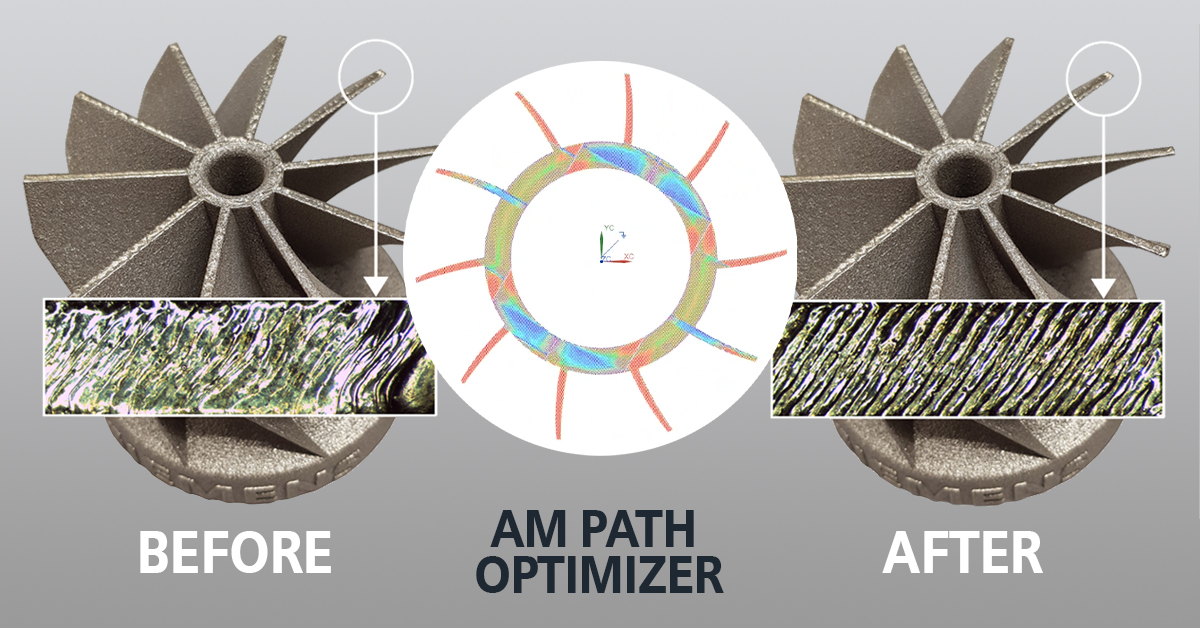

A new AM Path Optimizer product, currently under development at Siemens, will be part of a suite of solutions that help to identify and correct for print process issues. As you can see in the video below, the AM Path Optimizer simulates the deposition process at a Meso level through calculations of the thermal load on the system. The simulation examines the actual deposition path instructions for the printer and simulates heat buildup using that program.

The results of the simulation are then used to correct for print issues by adjusting the deposition path as well as machine parameters within the AM program. These adjustments reduce distortions and correct for small errors in deposition that can result in distortions, warping, or weaknesses in the printed part.

Helping our customers achieve first article print quality is just one of the things that Siemens is doing to further the industrialization of additive manufacturing. The AM Build Optimizer is only one tool in our suite of solutions for assisting with print quality, but it is a powerful tool that companies using additive manufacturing can certainly benefit from.

About the writer:

Aaron Frankel is Vice President of Siemens’ additive manufacturing software program. He has over 20 years of experience in the PLM software industry and has held various positions in engineering services, product management, and marketing – all focused on helping manufacturers take advantage of the latest digital design and manufacturing technology.