Ecurie Aix uses Simcenter Amesim and Simcenter STAR-CCM+ to reduce cooling system energy consumption

Ecurie Aix Team students from RWTH Aachen University reflect on their collaboration with Siemens and their experiences using Simcenter™ Amesim™ software and Simcenter STAR-CCM+™ software to reduce cooling system energy consumption in their electric car for the Formula Student Germany. By partnering with Siemens Digital Industries Software, they executed the ‘Batterie Aix’ project. They efficiently combined experiments, systems simulations and computational fluid dynamics (CFD) to optimize battery thermal management, taking into consideration energy-efficiency, scalability, re-usability and future enhancements.

Building an industry-standard race car in one year

Ecurie Aix was founded in 1999 when students at RWTH Aachen University in Aachen, Germany, had the idea of creating a Formula Student team. Formula Student is a worldwide competition where over 800 academic teams worldwide design and build their own racecar per the regulations of the SAE and Formula Student Germany (FSG). The goal of the competition is to have the students design, manufacture,test and compete a racecar built in just one year. The Ecurie Aix team started building the internal combustion engine (ICE) driven car in 1999, and during the summer of 2022, it will race with its 10th fully electric racecar.

Each Formula Student event consists of static and dynamic disciplines. Static disciplines include an engineering design presentation, cost presentation and a business plan presentation. The dynamic disciplines test endurance, efficiency, autocross, acceleration, skid pad and endurance track drive. The most important discipline in each competition is the endurance event, which is 22 kilometers (km) long, split into two parts (each 11 km). Read more about Formula Student Germany 2022 here and here.

Ecurie Aix was one of the first German teams to participate in the Formula Student Electric drivetrain competition in 2002. It was looking for an efficient and reliable approach for the thermal and electric characterization of battery packs and understood they needed to combine and integrate several disciplines due to the complexity of the problem.

It is difficult to design good test protocols that are fully characterized. By using Siemens’ software, it was fully automated – we just got the documents and then we were good to go.

– Fabian Böhm, Student Engineer, Ecurie Aix

Using Siemens solutions to gain insight into battery usage

Electrical mobility range and efficiency is one of the most significant challenges in the automotive industry and one of the most critical aspects is battery thermal management. This discipline integrates several systems (cooling, batteries, etc.). It enables optimal and safe use of the battery pack, which is imperative for both racing and passenger cars. Automotive original equipment manufacturers (OEMs) must exhaustively test and characterize these battery packs to safely integrate them into the car cooling system – they need to trust them for decades. Simulation experiments are essential in covering a spectrum of operating conditions, such as lifetime and aging. In the racecar case, the rapid discharge is extreme, so simulation is essential to be safe yet efficient, not over-engineered, i.e. a cooling system that is not too heavy!

In the Batterie Aix project, the students needed to determine how to characterize the battery cells, optimally integrate the batteries in the vehicle to meet performance expectations and range requirements and achieve the proper design and correct dimensioning of the cooling system. The fundamental idea behind this project is to co-simulate the powertrain system and CFD cooling analysis using a wide array of parameterized experiments.

We needed Siemens’ solutions for battery and thermal simulations; modeling the battery and its behavior was a new field for us.

– Thomas Nyhues, student engineer, Ecurie Aix.

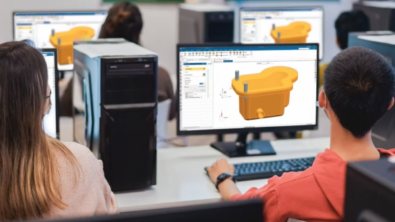

Executing the Batterie Aix approach

Instead of using a complex battery model to generate data, they conducted real-world experiments at the Institute for Power Electronics and Electrical Drives (ISEA) of the RWTH Aachen University. Using a multi-disciplinary approach for the electrical and thermal simulation of battery packs, the team combined electricalsystem and CFD experiments to provide valuable insights into battery usage and thermal profiles. First, they ran the battery testbench with different current profiles that were generated by using Simcenter™ Amesim™ software. Using the test results as input for the battery identification toolbox, the team could fully identify all parameters of the equivalent circuit model in Amesim. Furthermore, this fully parameterized model can now be used for making further steps and enhancements in the project. Simcenter is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services.

Next was the functional mockup interface (FMI) stage, where the team exported the fully characterized battery pack as an available mockup unit (FMU) with the FMI standard. This step enabled the exchange of temperature and heat flow. Finally, they ran CFD simulations, where they imported the FMU and characterization of the pack. From here they resolved time-dependent conjugate heat transfer simulation in Simcenter STAR-CCM+™ software, using a current profile that was recorded during an endurance race. The FMI and FMU standards are supported by both solutions and enable the software to communicate with each other without any complications. This feature was implemented in the software during the project such that the team was among the first to use these functions.

Additionally, the technical support provided by Siemens was a key success factor in this project. Claudio Santarelli, academic business developer at Siemens and Christopher Helbig, presales solutions consultant for system simulation at Siemens, guided Ecurie Aix throughout the project. As part of Siemens’ engagement with international student competition teams, the team was provided with online learning material and documentation.

We ran into some problems with coupling the software and using it for the first time, but Siemens’ support team always offered us a solution.” The team also had access to the Siemens Support Center, which had frequently asked questions (FAQs) and tutorials the students could access at any point during the project. They could also use the Siemens learning platform, Siemens Xcelerator Academy.

– Thomas Nyhues, student engineer, Ecurie Aix

Gaining realistic and trustworthy simulation models

This simulation setup could then be enhanced by experimenting with design changes to optimize the battery thermal management. Using Siemens’ solutions, the team gained more realistic and trustworthy simulation models, which enable them to reduce the time and resources invested in track tests and reduce costs.

The main aspect in our keys to success was the collaboration with the Siemens team. Siemens’ Simcenter STAR-CCM+ is a state-of-the-art tool for CFD simulations – especially for downforce and drag aerodynamic simulations, not only for cooling analysis.

– Thomas Nyhues, student engineer, Ecurie Aix

Furthermore, the simulations allow the team to access data and information that cannot be accessed with track tests. This opens new doors in the development process of the car.

It is difficult to design good test protocols that are fully characterized. By using Siemens’ software, it was fully automated – we just got the simulation output documents and then we were good to go. “The collaboration with Siemens’ support team was the driving power behind the project.

– Fabian Böhm, student engineer, Ecurie Aix

Once the battery cooling system was correctly simulated, the team could take advantage of it during the car’s development process. For example, reducing the cooling system’s size and weight gave Ecurie Aix an advantage over other teams.

Siemens enabled us to get into the software and tackle any problems that arose during the project. I am still overwhelmed by the motivation of the Siemens team. It felt like they were part of our team and had the same goal. As a team, getting new members quickly up to speed is necessary to be more effective so the documentation we developed with Siemens enables us to do so.

– Luca Leogrande, student engineer, Ecurie Aix

Implementing battery model in real-testing approach

The team is looking forward to using Teamcenter® software for several aspects including documentation and change management. “These two points make Teamcenter interesting to us,” explains Leogrande. The team will also implement the battery model in the real-testing approach, such as software-in-the-loop (SiL) and hardware-in-the-loop (HiL). It is anticipated future work will include using the battery model in the lap-time simulation using Amesim and for a real-time controller.