Podcast Transcript: Digitalization Impacting Engineering Education

On this episode of Innovation in the Classroom, our host Dora Smith speaks with Michelle Boucher and Sirin Tekinay. Two engineering professionals helping to shape the future of the industry.

Hear from Michelle Boucher, the VP of Research for Engineering Practices at Tech-Clarity and Sirin Tekinay, the Dean of the College of Engineering at the American University of Sharjah about best practices for industry and academia collaboration and how students are adapting to a completely virtual learning environment.

Podcast Transcript

Dora Smith: Welcome to Siemens Innovation in the Classroom Podcast series. I’m your host, Dora Smith. Listen to hear some of the brightest minds in engineering education, share insights, and best practices to empower the next generation, a digital town.

Dora Smith: Welcome to Siemens Innovation in the Classroom Podcast series. I’m your host, Dora Smith and today I’m joined by two wonderful guests, Michelle Boucher of Tech-Clarity, and Sirin Tekinay of the American University of Sharjah, and also representing the Global Engineering Dean’s Council. Welcome to the show, Michelle and Sirin.

Michelle Boucher: Thank you, Dora.

Dora Smith: So, to kick us off, I’d like each of you to share a little bit with our listeners about just some of your background, and what brings you to our discussion today. So, Sirin, if it’s okay, we’ll start with you.

Sirin Tekinay: Thank you, Dora, with the American University of Sharjah, I’m the Dean of College of Engineering since February of this year before this, I upheld academic administration positions serve the US National Science Foundation. I’ve always been an electrical engineer in the Electrical Engineering Faculty. So, for the first part of my career, I was a hardcore electrical engineer, but in the last decade or so, I decided to play forward the opportunities that I got as a woman in engineering. So, on top of my regular engineering, education research, I work on diversity and new ways of improving engineering education in general. And of course, the Global Engineering Dean’s council that I’ve been working with, since 2012, has the same agenda except on a global level. So, I’m pleased and privileged to be here to represent them also.

Dora Smith: Sounds like you never have a dull day. All right, so how about Michelle, can you share a little bit of your background?

Michelle Boucher: Certainly, yeah. So, my background in mechanical engineering, I worked in the industry for several years, designing equipment for the injection molding industry. And then I worked for a few different software vendors that I had a lot of experience working with them. And they all develop products, or software products that support product development. And I’ve spent a lot of time working with a lot of engineers and helping them with their software problems and seeing kind of the areas where they struggle. And then for the last about 10 years, I’ve been studying trends and product development and looking at some best practices. And I’ve done a couple of different research studies on looking at the engineering skills gap and what different companies are looking for in new engineers when they hire them. And then also some research looking at different schools, and some of the best practices that they’re employing to help develop real-world skills and engineers.

Dora Smith: So, it’s that research that really kind of brings all three of us I think together today, right? Because we’ve been involved in it, collectively. So, let’s talk a little bit about the skills gap research. And just so everyone’s aware of from our listeners, this is available now in an E-book that you can download from Tech-Clarity or Siemens. But to share a global perspective on what schools are doing in this age of digitalization. And I guess Michelle, um, the first question, I’m curious. Did you find that there was global consistency and how colleges and universities are embracing digitalization and reshaping their curriculum?

Michelle Boucher: Yeah, that’s a really good question. There’s definitely a global agreement that digitalization is really important, there’s a lot of agreement that it’s going to shape the future. But I’d say probably the level that schools are embracing it as a little bit different and even their view of digitalization is a little bit different. Some schools are viewing it more as just having electronic files, or others are taking more of a broader view. And really looking at digitalization and embracing digitalized processes and looking at Digital twins and maybe the impact of a digital thread throughout an entire project. That’s not unique to education and that’s true of the industry too. And there’s just a lot of varying levels of maturity. It’s a newer concept. And so, companies view digitalization in different ways to deal with different levels of maturity. I’d say overall, probably schools in Europe and Asia are probably taking a little more of a mature view when how they’re embracing it and how they’re using it to reshape their curriculum, but it’s definitely something everyone is looking at, and everyone seems to be really working on learning what they’re going to need and figuring it out.

Dora Smith: Okay, great. And maybe to speak to that region’s view, I guess and even your view from the Global Engineering Dean’s Council. Sirin can you share more on your perspective? That was noted in the E-book about particularly you talked about changing from a push to a pull approach in engineering education.

Sirin Tekinay: Yes, thank you, Dora. This is the silver lining of the pandemic if you will. We always had a technology-supported learning platform and wanting to go more towards project-based learning and blended learning with our students, the flipped classroom model, and so on. But over a course of three days, we had a hundred percent online delivery all of a sudden when the goal for the year was about 15%. But of course, this can only happen at institutions where there is the instructional infrastructure ready to support this. The first semester that we did this, in the middle of the semester was challenging, because we already had the syllabus in place, we knew what we wanted to do for the rest of the semester. So, we wanted to mimic, we wanted to come close to what it was that we planned for that semester with 85% of our courses. But now it’s a different ballgame. Maybe I’ll say that preparedness for the next question, but what I would like to share at this point is that the technology readiness level of institutions has really discriminated against them across the globe. When we look at it, from the point of view of the Global Engineering Dean’s Council, we always had those institutions who are trying to hold on for dear life at the edge of that digital divide, when it comes to good internet access. Now we’re pushing all of the engineering education on to the virtual platform, where there is a lot of synchronous versus synchronous learning going on. At any rate, the students need to pull the information they need in a project-based problem-based learning setting, whether they have good access or not, as opposed to the good old fashioned come to class will give you information will push it on you and trust us you need it. It’s necessary information for you, as an engineer, kind of approach which you cannot address Generation Z, who are our students now, and definitely not the upcoming generation, Alpha.

Dora Smith: So, it sounds like you have to make adjustments both I guess in the content and then the way you serve up that content so they can pull it when they need it. You’ve talked just a little bit about this and how he had to shift the curriculum and learning styles have changed. Have you seen any difference this semester than you did last? Or is it just you’ve learned enough in that quick adaptation and just now can be more effective this semester?

Sirin Tekinay: Absolutely. It’s a different ballgame this semester, we have the whole summer to prepare for end to end online, therefore, virtual delivery mode, especially in engineering virtualization of experiential learning. Of course, has been extremely challenging for us last semester, when all we wanted to do was to complete the teaching outcomes that we had signed off on for the semester, which is, of course, our syllabus with the students. Last semester, our aim was to simply come close to the face to face or simulate the face to face version of our courses. Whereas now we can take advantage of the new opportunities virtualization brings us. We have new software for collaboration for virtual labs, summer, augmented reality-based interactive, immersive brings together theoretical foundations with the experiments in the labs of something we could not do in face to face physical labs. So, we’re much better prepared, and we’re enjoying the shift in the engineering education approach quicker than we had anticipated. So, we’re not letting a good pandemic go to waste.

Dora Smith: That’s a positive way to look at it. So, let’s shift just a little bit though, and talk specifically about the students. How have you found them adjusting to this new normal?

Sirin Tekinay: At first, our students did better than the faculty because they’re born into technology, they’re digital natives. Whereas a lot of faculty, especially the senior ones who have been teaching in a more traditional manner, were apprehensive about going online. But students first took it like a duck to water, there was no problem but then, not having campus experiences, not being able to work in the labs with their teams started to have adverse effects on our students. Our counseling services, seeing a lot more disturbances, and we feel for them on the other hand, I have to confess it’s a complete ego buff to hear our students tell us, they miss us, they want to come back to the classrooms, and labs. Nevertheless, we’re trying to simulate some campus experiences, especially for first-year students, going to college is a huge turning point – wasn’t it’s? – in all of our lives but now they’re stuck at home, taking a bunch of online classes. So, we’re trying very hard to offer some campus experiences for them, teamwork, and projects for them as best we can. I think the new normal will be a combination of what we have right now, but definitely some experiential learning the good old-fashioned way.

Dora Smith: Recently, through GDC, you guys held an industry forum and I think you had a student challenge that really touched on this topic, you called it Thriving Online. Any takeaways from what the student teams presented in that give us any other ideas I guess, or solutions to sort of address this, this mental health and need to connect still in this purely online world?

Sirin Tekinay: It’s an area that opened up for more discussion and research. We also have an upcoming annual conference in a couple of weeks, where we will have many more students’ workshops, and sessions and student life related sessions where mental health issues will also be taken up. So, now we’re looking at it’s not with any kind of stigma, but as part of modus operandi that we need to be careful about what the virtual world is doing to our real world. The takeaways are, that the generation that is born into technology, who is effectively using the virtual world needs a purpose. When the interaction is purpose-oriented our students do much better. Then the boundary between the real and virtual worlds freely becomes thin, very transparent and they’re more comfortable using different modalities of communication and interaction through the day, as opposed to continuous listening to lectures or trying to learn from one lecture online.

Dora Smith: That purpose might also be the answer to this next question, but we’ll ask Michelle to maybe share a little bit more. Michelle, what do you think is key to really keeping this pace of innovation and continuing to progress towards digitalization to really prepare these students for working in industry 4.0?

Michelle Boucher: That’s a great topic to even be thinking about, that pace of innovation because it’s just accelerating. And in companies that can’t keep up, they’re just going to struggle to compete. And that’s actually what’s driving a lot of these strategies, to embrace digitalization. Because companies are really viewing it as a very critical way to help them become more agile so that they can innovate more efficiently and beat their competitors to market. So, looking at some of our research, in order to make digitalization a success, the right technologies obviously going to be incredibly critical. But you also have to have the right corporate culture to really support an agile business, and to allow companies to take advantage of some of those efficiencies that they’re going to achieve through digitalization. So, one of the things that our research found is that agile business really has to have an organization that’s going to be flat. And it’s going to be more made up of empowered network teams that are very cross-functional. And it has to support a very collaborative culture. So, to make that a success, companies really need to have highly skilled staff. And to support that, that staff needs to be digitally native, they need to be very comfortable with applying technology to solve problems, and really embrace a digital mindset. And then also to help support those teams, they’re going to need leaders that are really comfortable in that environment and can function as a horizontal leader. So, they’re going to have to have people that can work not only in the engineering disciplines and across multiple engineering disciplines, but also feel very comfortable interacting with other departments like manufacturing and procurement, and finance. So, it’s going to be really critical that our future engineers have skills like that.

Dora Smith: Digital mindset, I love that phrase. That’s something we preach a lot when we’re reaching out to schools. So, noticing the research emphasizes was industry collaboration to better prepare students, so a little fun exercise here I want to ask each of you to give a grade to the current relationship between academia and industry. And then I’ll ask you to address a little bit more. But, Sirin, let’s start with you. What grade would you give that collaboration right now?

Sirin Tekinay: If you ask me the question last year, it would be a C. But now I think I’ll say B minus.

Dora Smith: B minus, Okay. And how about Michelle, from your perspective?

Michelle Boucher: I need to elaborate a little bit on that because it’s really interesting when the schools that I spoke to have really phenomenal programs in place, and they really done a very good job engaging the industry. And many of them commented that they even have industry partners, more industry partners are poaching them, that they can even accept. So, if they’ve got these great programs in place. So, I mean, for schools that have programs like that, I think they’re doing a great job and I’d give them an A. And the industry partners who are engaged in those programs, I’d also give them an A, because they’re really involved in these programs. They’re mentoring students, they’re helping develop skills that the companies are going to need in a new hire, they’re developing really great relationships with students. So, it’s going to help them identify good students that they will want to hire full time. And so because of some of their involvement in some of these programs, the students are really familiar with the company, and it can help that company develop a good reputation on campus, so it can become an employer of choice.

Michelle Boucher: So, those are perspectives, I think they’re really doing really well, but looking at a broader perspective, and from a survey that I’ve done, there’s a lot of room for improvement. And looking at schools, overall, industry reports that they’re struggling to find engineers with the right skills. And some of my past research, we found that 46% of industry respondents say that the new engineers that they hire just lack really good problem-solving skills. And they want students to be able to apply technology to solve problems. And so, we found that 81% find that new hires are not prepared to apply technology, and they need significant training. So, I’d say schools, for the most part, are headed in the right direction, but there’s a lot of work to do so I give them a B overall. And then for industry, I’d say from those past survey results also, the industry felt like they should be involved in the curriculum. And on average, they felt that the industry should be involved in about a fifth of the curriculum. But what was really interesting is 43% of the most successful companies – and we call them top performers – they said they are involved in the curriculum about that much. But then when you looked at less performing, average performing companies, 62% are barely involved if they’re even involved at all. So, the ones that have embraced this collaboration between academia and industry have been doing it really well, they can attract top talent. But the ones that are not as involved, they feel it should be and they’re struggling to find the right skills. So overall, I would give companies more of a C because they’re not as involved as they should be. And they recognize they should be, but they’re viewing it more as an expense rather than an investment in future talent.

Dora Smith: Sounds like we got a bell curve there on the grading. So Sirin, let’s come back to you. And what forms of collaboration have you seen most effective, both at your university and what you’ve seen from your colleagues in the Global Engineering Dean’s Council?

Sirin Tekinay: I think practicing what we preach at the Global Engineering Dean’s Council, we’re diversifying the portfolio of modes of interaction with industry because even the modes of interaction were siloed. Up until recently into sponsored research that faculty did with industry or internships, employment recruitment, the more human resources related part of the company would interact with the university. And the two wouldn’t talk to each other, these were two separate modes of interaction. Whereas now, as Michelle just suggested, there is an excellent point where first of all, at the university itself, education and research and innovation and design are all coming together, getting integrated, they’re not siloed at the university. So now, the university interacts with industry that may now have a say, on the curriculum, when they complain about the lack of the skill set and so on. But also, when there is collaboration on research and development, this can be at the undergraduate level, there could be senior design projects, project-based courses. So, now students and industry are a lot more interactive, as opposed to faculty and industry, which makes the collaboration. So, that’s the improvements, the theses, dissertations, projects, bachelor’s projects, senior designs, all of these are student-driven now. And if we can establish problem-based learning with the pool mentality in the students, then they will enrich industry relations, all the better.

Dora Smith: That’s great. And I think, just a couple of recommendations for companies that are listening to this. Michelle, your research, this latest one is a little bit more guide to academia, but previously was a roadmap for companies for how they could engage. So, I encourage people to go back and look at some of those recommendations and share and the other thing that came to mind was, I encourage the companies to get engaged in these virtual internships, the GDC, set up a platform. It sounds like you guys have had a tremendous response that already but we can always use more, right?

Sirin Tekinay: Absolutely. We’ve been very pleased that the maiden voyage of the global virtual internships program last summer – because we formulated it last summer as a response to the pandemic – was wildly successful in that more than 36,000 views of the webpage around the globe, signaled a lot of interest. And now there are all these requests that we’re getting from various parts of the world for the continuation of the program.

Dora Smith: Michelle, you noted in the E-book, and you’ve talked about it here on the podcast as well, the new corporate culture requiring that agility and horizontal leadership. We’ve also seen some brand-new skills gap data from some research I was doing with the American Society of Engineering Education through the Corporate Member Council. And some of the feedback therefrom fresh engineer hire – so, these are new hires within the last five years – was that they wish they had more finance and business acumen. And I wondered what recommendations or examples if you heard any and your research that integrated those topics.

Michelle Boucher: Yeah, that’s a great point, because we are finding engineers need to know more. In several schools actually did, yes, they did mention that they’re involved in one of the examples that they talked about was extracurricular projects that are really cross-functional. And they’re made up of teams that go beyond engineering, but also involve finance people, and they have to manage a budget. So, a couple of examples that that schools mentioned with the Mars Rovers project are a really good example is they they have to manage a budget, and they actually have to submit a finance report as part of the competition. Another one was the Baja SAE competition, which also requires student teams to submit a report for the cost of their car. So, projects like that are such a great experience for a young engineer, because it really forces the designers to think about the impact of their costs, the impact of their decisions and the impact on cost. And they have to work with a finance person to help them make sure they’re staying on budget and understand how the work they’re doing impacts the entire budget. So, those are just a couple of examples of really good practical experience with finance.

Dora Smith: Great, I think many of those extracurricular projects helping in this next area we’re going to talk about too and teamwork and communication. But let’s shift back to you Sirin and the research noted collaboration and the importance of soft skills. And so, my question is, how do we teach students soft skills, especially right now, without this typical in-person interaction we would have in the classroom?

Sirin Tekinay: Well, now the technical communication skills that we always needed became a lot more important. Students are globally connected, that Generation Z is the first truly global culture. They’ve always been globally connected and now with engineering schools, connected through the Maker Movement, through the Fab Lab network, through many global and international student organizations. Technical communication, online communication, good articulation of systems they’re working on collaboratively, is extremely important. So, it’s a different kind of soft skill that they have to learn. Maybe they won’t know to hold the door for you. But they will share different parts of a project efficiently because they simply have to.

Dora Smith: I think you’ve said before too, how you kind of channel if they’re anxious or frustrated in a constructive way. Just my son’s school emailed something this week that I thought was worded, well, where it said, “Be curious when you’re furious”, right? Don’t give up use it as an opportunity to try to learn more.

Sirin Tekinay: Yes, absolutely. If I may, just that Generation Z is the first globally connected technology generation but their little brothers and sisters are extremely purpose-oriented, and they’re angry and anxious. And it’s our job to channel that energy, as you suggested into these constructive, sustainable development goals, and so on.

Dora Smith: Michelle, you noted in the E-book that schools were educators were talking about restructuring and removing content so that they could embed more project-based learning. Did you hear from educators that that is happening and what challenges that kind of change brings to their administration?

Michelle Boucher: Yeah. I mean, that came up several times. And as we were talking about it, and as we mentioned earlier, the engineers have to learn more. But the curriculum is full, so you have to figure out how to add more if something has to come out. So, several people mentioned that they had really strong opinions about how to do that. Several felt very strongly that a lot of the theoretical work that engineers are doing in their coursework just doesn’t have a practical application anymore. And then that’s really useful for research but preparing engineers for their careers, it was a lot less useful. The challenges that they’re running into is that these traditional approaches to teaching a lot of theory, are just so ingrained in the curriculum, it’s really hard for school administration to accept that change. And leadership really has to buy into the idea that some of the education is more practical based and theoretical based. And that’s going to require structural changes to the curriculum, which is very hard to do. But I did see some professors talk about how their schools are embracing it, what they’re doing is they’re embracing more of an integrated curriculum, rather than having a lot of individual siloed courses, for a few credits each, they’re combining multiple topics, and even maybe involving multiple professors for a single class. It’s more of a multi credit course, with a lot of integrated concepts. And that’s actually more of a real-world experience for students as well and it helps to cover a lot more topics in a single course that way.

Dora Smith: Sirin, maybe I’ll shift to get your perspective on this. Just yesterday, I was talking with a Dean, who’s an ABET evaluator, and because we often hear in these industry-academic discussions, one of the challenges is – just as Michelle was talking about – what do we take out to put in more of what industry needs. And often people will say the challenge is, well, we’ve got this accreditation and these the criteria we have to meet. But this evaluator is just saying it’s interesting that in the criteria there’s actually a lot of room for creativity. It’s a rigorous process but we often still try to measure ourselves by the typical classroom and you can get much more creative in meeting those criteria. So, I guess I just wanted to see how your own school has evolved and what are you what’s your recommendation to other Deans around the globe about how we address this?

Sirin Tekinay: That’s an excellent point and it’s actually one of the missions of the Global Engineering Dean’s Council. We want to share best practices improve engineering education and as we do interesting, radical things, like taking out a lot of the traditional curriculum, saying students can pull that information, and then turning things around in a more problem-based way, which is what the industry prompts. We worry about accreditation because courses are anchored in their learning outcomes and accreditors will have to come in and see that the students got those outcomes at the end of the semester. But accreditation bodies are also part of the Global Engineering Deans’ Council, so they are building these flexibilities into the requirements, or how they’re measuring the outcomes is becoming more flexible. Only recently at my university, we had a lovely exchange with Siemens, in fact, for one of the certification programs. That’s another area that university and industry can go back and forth, we don’t need to necessarily modify the sacred curriculum so that would present a risk of losing accreditation or being at odds with accreditation criteria. But there is a lot more we can do in the way of short courses, training programs, both ways. Industrial folks, our colleagues there need pressures and new training programs. And we need – both faculty and students – training certification programs, short courses, intense courses in order to keep up to date. We keep preaching continuous education, we can’t simply expect that out of these 14-week classes within the curriculum.

Dora Smith: Yeah, definitely a lot more flexible options. I think, going forward with certification, credentialing, badging, we’re definitely seeing some opportunities there for good industry-academic collaboration. So, Michelle, it was interesting to see some educators that you interviewed, they noted an improved learning experience during COVID-19 with more digital platform adoption. I just wanted to find out from you, did you get a sense that academia is enriching learning with technology and leveraging software, hopefully, what Siemens provides? What’s your sense there?

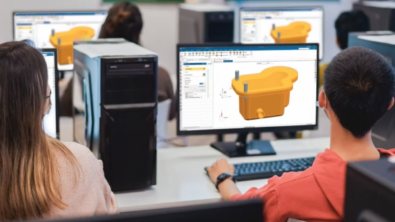

Michelle Boucher: Yeah, I mean, that was really interesting. COVID brought so much change, and so quickly that the educators had to adapt really quickly, and they didn’t have a lot of time to prepare. And so, the educators that I spoke with, they comment on how it forced them to think differently and they had to make this mental shift. And those that we’re leveraging technology, they were actually very pleasantly surprised that how much that technology made it easier for them to adapt. So, some of the things that they talked about were, rather than purely online lectures, educators are able to offer some really engaging educational experiences with digital platforms. And just as one example, when mentioned how just using PLM, helped them to actually have more visibility into what individual students were doing. And then because of that, they could provide more individualized feedback to that student, which wasn’t really possible before in a traditional classroom environment or in a lab. So, they found that really interesting and really helpful and felt like they could give better guidance that way.

Michelle Boucher: And then another example was, rather than focusing on building something at the end, that final deliverable, they could spend more time on some of that upfront work that is really critical in a true project and work environment, but doesn’t always get covered in schools. But because they were using digital tools, they can spend a little more time in the upfront part and focus on requirements management. Or are looking at different concept designs, to explore different ideas and using the software to help them with that, and kind of learning how the software can be an aid to help arrive at a better idea and better requirements, better design before you even start the digital design.

Michelle Boucher: And then a final area was without possibility to do physical labs, some were looking at doing virtual labs, with simulation software to test different design concepts. One Professor talked about how in his course, they always work with a lamp, that was impossible. But what he did was he adapted to a digital twin of that lamp and before, there were always very limited to what that physical lamp could do, but now by using a digital twin, they can make changes to the lamp and try out different ideas that wouldn’t have been possible before. And because of that, the students could see how different things impacted their ideas and it really helped them understand and have a richer educational experience because they’re really truly testing and seeing the impact of different thoughts and ideas. So, as tough as it is, there’s also a lot of really good opportunity to improve education.

Dora Smith: Yeah, I love to see that innovation. I also love the idea of leveraging the tools like PLM not just for how they’re traditionally used to manage the product and the process but to engage and help in managing the people. Sirin, I wanted to see if there are some key trends that you’re seeing in the classroom, I think you touched on a few in the E-book that changed the way we teach technology. Any other trends you’re seeing or thoughts you have for the future of engineering education?

Sirin Tekinay: We definitely are going towards this new era where routine jobs are simply eliminated. Artificial Intelligence, machine learning are eliminating those jobs that can be learned and replicated. Whereas design thinking with the need analysis at its core, the empathy step, the human-centric approach is what we need to teach our students and it’s the approach engineers have to maintain throughout their lives. For example, there’s no longer a test engineer for a certain component at any manufacturing plant anymore. The job has simply been evaporated, on this, there are test engineers who are improving the testing process, the design of the system. So, the job has changed as such the innovation teams, RND teams, designers, design teams, those are expanding. So, we need to always teach our students how to continuously improve processes, never take the senior engineers word for “Well, this is how we do it.”‘ It will not be how we do it from here on. So, critical thinking, questioning, and constantly learning and creative minds will have to be raised and I see that in our students already. They always question why, why should we do it this way? I think we can do it better this way. Those are really engineers of the future.

Dora Smith: Curious, not furious.

Sirin Tekinay: Exactly.

Dora Smith: Alright, so coming towards the end here, the Ebook, Michelle, that you put together has some good recommendations and next steps primarily for academia. Selfishly, I’d like to ask you guys, as we end our podcasts to give us some feedback for what technology companies like Siemens can do, how can we better serve academia to accelerate change and innovation? And maybe Michelle will start with you?

Michelle Boucher: Yeah, I would say, I think probably everyone I spoke to stressed how important it is to have a good partnership with industry and that, they need direction from industry to help them adapt their curriculum and make sure they’re developing students that are going to meet the future needs. So, they’re really hungry for that direction from the industry. So, I think as Siemens with all of your many customers across multiple different industries, you’ve got a fantastic perspective of how engineers should be working and could be working and how technology can make their jobs easier. And I think for academia, that’s especially critical because a lot of them have very academic backgrounds, but less practical experience. Siemens, as a company can help provide some of that practical experience to them, and help them understand how technology is evolving, and offer your perspective on the direction of where your software is going. And the vision for how you see your software, enabling some of these modern technologies that we’ve been talking about – as Sirin was just talking about AI and machine learning – and how your software can help engineers work with that more easily. And you’ve got your pulse on the latest and greatest technologies like 3D printing, and IOT, digitalization and so, you can help the company, the education to adapt the curriculums to prepare modern engineers.

Dora Smith: Great, Michelle. That’s actually, yesterday, we had a call with one of our large customers in aerospace. And we’re talking about how could we help bring educators into their workplace and maybe as a reverse sabbatical, so they can really see firsthand how they’re using the technology. So, some good ideas there. All right, Sirin, we’re gonna let you have the last word on this question. What feedback do you have?

Sirin Tekinay: Famous last words? Thank you. Well, at an individual level, we know what the industry needs at the output when it comes to our graduates. But the more interactive, the collaboration is with the industry through the education of our students through the projects that we have in our classes, or the design, or the capstone projects, theses and dissertations, the more we’re guaranteeing that output to be what we need the employable graduate, the adaptive engineering leader that will produce. So, the multimodal interaction, from the curricular side and design and research and development with faculty and students alike is extremely important. That’s the individual level. But at a global level, Dora, with leaders such as yourself – you’re holding a seat on the International Federation of Engineering Education Society’s Executive Committee – we need more involvement with directions with the new technologies that have been changing the face of the planet. I don’t think the next industry revolution will have a version number like a nice big fat 0 number, it will be continuous. So, we’re already living but 4.7 or so I’m sure because there have been disruptive developments every day. So, we need to start defining the version numbers on industrial revolutions and keep continuously working together to assure new advances every day.

Dora Smith: I’m glad you mentioned EES and I know you had said to the GDC is going to be opening up some seats to the industry. So, one more plug for all my industry friends, there’s plenty of volunteer opportunities to get engaged in driving this change between academia and industry. Thank you both. Thank you, Sirin and Michelle for taking the time to share your insights on classroom innovation. And thank you to our listeners for tuning in. Hope you enjoyed this and if you did, be sure to subscribe and listen to more of our Innovation in the Classroom podcast series.