Making Digitalization Tangible: How to excite the next generation for future technologies by experimenting with CAD & 3D Printing

While the theoretical aspects of what digitalization means can be taught in school, the real opportunities that digital concepts and product development offer can only be experienced on-site, ideally at companies that have it ingrained in their DNA – just like Siemens.

Unlocking the World of Digitalization with 3D-CAD & 3D-Printing Courses

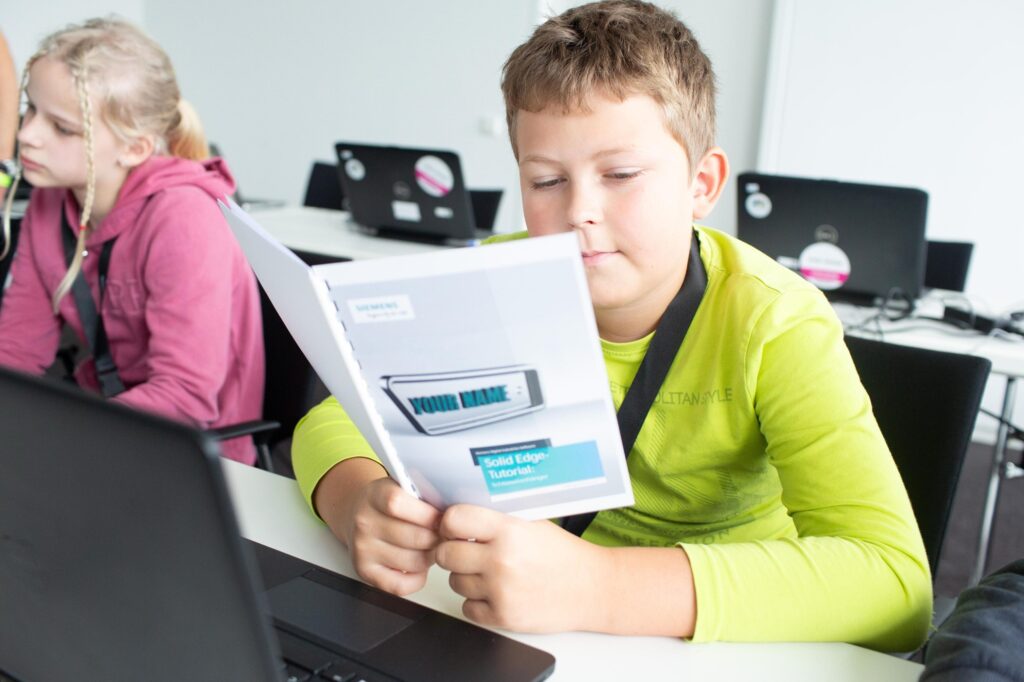

One way to delve into the topic a bit deeper and make it still understandable for a younger audience is through 3D-CAD & 3D-Printing courses and tutorials, many of which are offered by Siemens Digital Industries Software. One of the beginner courses that is particularly popular and introduces the concept of the digital twin in a smooth, easy, and understandable way is probably our name-tag tutorial.

So, this format has become almost evergreen whenever we aim to excite kids about topics like CAD, digital twin, 3D printing, additive manufacturing, and so on, whether it is at the Munich Urban Colab, at the Telekom Digital@School Campus, with one of our Siemens partner schools or online, being part of the Digital Alliance initiated by the Bavarian Digital Ministry.

Inspiring the Next Generation at the Munich Urban Colab

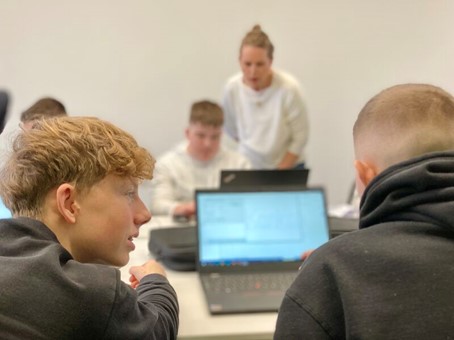

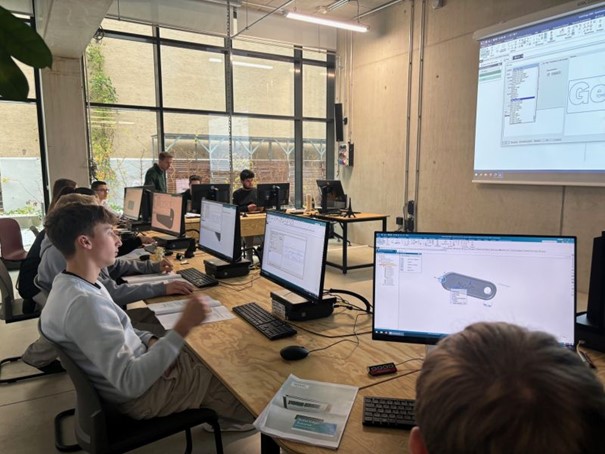

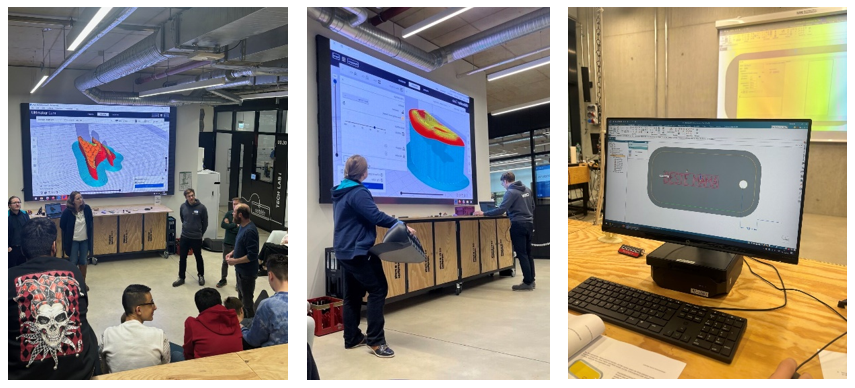

In December 2023, four classes from Munich with different educational backgrounds – from middle school to highly gifted classes of a high school – were able to take part in our design workshops at the Munich Urban Colab to design their own name tag using Solid Edge software. The #SiemensMovesSchools workshop series was organized with UnternehmerTUM MakerSpace GmbH and the ReDI School of Digital Integration Munich. The participants were always supported by students from the Siemens Maker Space.

Hands-On Design Workshops: A Gateway to Future Technologies

“Of course, the focus is on doing. Designing a digital twin yourself, which is then printed on a 3D printer and possibly given to your mom as a gift, is a highlight for everyone,” says Susann Kunz, workshop leader and part of the Solid Edge marketing team. “However, it is just as important to us to provide the appropriate context. Why do you need digital models these days? What advantages do they bring?”

It is important also to impart some general knowledge to the young people in the workshop. After all, everyone knows the brand, but very few people know that Siemens no longer produces or sells household appliances such as washing machines, dryers, or vacuum cleaners. Instead, the company’s target group has clearly shifted towards B2B.

Questions like “What does Siemens actually do?”, “What did Werner von Siemens actually invent?” and “What is behind the terms CAD and digital twin” are therefore always asked, discussed, and answered at the very beginning. “We aim to spark early enthusiasm for STEM among students, showcasing how science and technology positively transform the world,” says Stefan Zeidler, member of #SiemensMovesSchools initiative, working as a Team Lead at Talent Relationship Management of Siemens Professional Education. “Our goal is to present Siemens as an outstanding training ground and innovative employer, emphasizing groundbreaking innovations in smart infrastructure, digitalized industries, and a commitment to sustainability and ‘Technology with purpose. We strive to engage young minds, provide guidance, and attract them to apprenticeships or dual study programs at Siemens.”

Practical Application: Bridging the Gap Between Learning and Doing

In the second practical part of the workshop, the students have the opportunity to practically apply what has been shown and to work with software that engineers from large companies such as Dyson, Hymer, or Voith usually work with. Jakob Illner, Community Manager from the ReDI School of Digital Integration Munich and co-organizer of the workshops said, “The students were able to see the variety of exciting tools that the Makerspace offers and what is possible with CAD software in product development. The tour and the workshop made it clear how important it is to quickly test designs using 3D printing for start-ups, large companies, and also students when designing their key rings!”.

Simon Sperlich, a technology teacher at the Middle school on Wittelsbacherstrasse, also enthusiastically added, “By combining theory and practice, the students were able to gain a completely new insight and learn how CAD works using a specific example.”

Wrapping Up the Experience: Tours, Pizza, and Future Partnerships

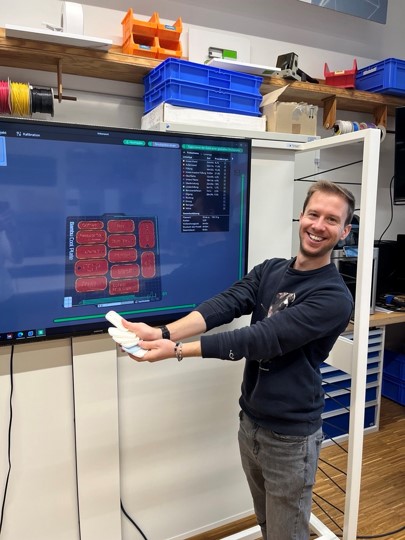

The workshops were always completed with a tour by Michael Lorentschk through the MakerSpace high-tech prototyping workshop area in the Munich Urban Colab. “At UnternehmerTUM MakerSpace, we believe it’s crucial to balance our digital workshops with hands-on experiences, particularly through 3D printing.” Michael Lorentschk highlights this approach, stating, “We let participants feel different 3D printing techniques and take home their own 3D-printed nametag as a personal workpiece. These collaborative workshops with Siemens align perfectly with our youth program’s overall goal, so we’re eager to maintain this partnership. And, of course, we wrap up each course with a tasty pizza, because even smart brains need good food to thrive.”

School classes from grades 8 to 12 who are also interested in such a workshop are welcome to contact siemensbewegtschule.de@siemens.com.