Customer Success with the Siemens Xcelerator for Startups program: VCycene

This month we sat down with one of our newest clients, VCycene, to discuss their startup journey and experience with Siemens’ design and simulation software tools. VCycene was introduced to Siemens via their membership with VentureLAB, Canada’s premiere lab/incubator for founders building hardware and semiconductor-focused products.

How did VCycene get its start? What inspired your startup journey?

“VCycene was born out of a deep commitment to sustainability, and designed to help households achieve zero waste and take real climate action at home. Founded in 2021 by George Yin and Huayi Gao, the idea was sparked by George’s experience in solar energy and vertical farming, where he saw the untapped potential of transforming food waste into value. Partnering with Huayi, an expert in advanced engineering, they set out to address the growing global challenge of food waste. Our kitchens are the single largest source of organic waste in landfills, and keeping food we don’t eat out of landfills is one of the most practical and efficient ways to combat climate change. That’s why they created the LILA Composter—a one-of-a-kind technology tackling this problem right at its source: our kitchens. By turning food scraps into high quality, organic compost, LILA makes sustainable living accessible.”

Tell us about your experience with VentureLAB: How’d you get started, how did they help you in terms of milestone achievement, and what’s your relationship with VentureLAB like today after you’ve been engaged for a couple of years?

“We joined VentureLAB because of its exceptional track record in nurturing hardware-based startups and its reputation for providing a comprehensive support system. VentureLAB’s ecosystem offered us unparalleled access to critical resources, including expert mentorship, strategic networking opportunities, pitch competitions, and funding guidance, all of which were pivotal to our early success. One of the most valuable aspects of our partnership was the access to their state-of-the-art facility spaces, where we could prototype, test, and refine the LILA Composter. This hands-on environment played a key role in accelerating our product development, ensuring that we could rapidly iterate and improve our design.

VentureLAB’s support went beyond just the technical—helping us navigate the complexities of the startup world, from securing investor interest to fine-tuning our go-to-market strategy. Their assistance was crucial in reaching significant milestones, such as launching the 3rd generation of the LILA Composter, which gained substantial traction at trade shows and within the local community. Today, our relationship with VentureLAB continues to be a cornerstone of our growth. We remain engaged with their network of experts and fellow innovators, constantly refining our strategies and scaling our business to make an even greater impact in the sustainability space.”

You worked closely with Siemens partner Maya HTT in the selection of your software tools. What was that like?

“Our working experience with Maya HTT has been great. We received responsive support and recommendations in selecting & implementing Siemens’ design and simulation software tools. We are looking forward to continuing our conversation with Maya HTT along our product development progress.”

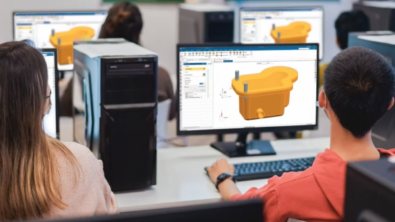

What Siemens tools do you use, and how do you use them?

“We use Siemens NX to design and optimize the LILA Composter, leveraging its powerful tools in several key ways. NX enables seamless organic surface modeling, allowing us to create complex, freeform shapes without performance issues, essential for the composter’s intricate design. Its advanced parametric and direct modeling capabilities streamline our design process, ensuring precision and efficiency in creating mechanical components. Additionally, NX excels in managing large assemblies, helping us handle the composter’s complex internal structure while minimizing delays. With its proven stability, NX ensures we can confidently work on intricate designs without crashes, making it an indispensable tool in our product development.”

Tell us about your product and the challenges it tackles.

“The LILA Composter is a revolutionary solution designed to address one of the most pressing environmental challenges—food waste. By tackling organic waste directly at its source—our kitchens—the LILA Composter offers a practical, effective approach to promoting a circular economy and sustainable living. It empowers households to convert food scraps into high-quality, organic compost right at home. This not only reduces the volume of waste sent to landfills but also creates high-quality, organic compost ideal for gardening. Packed with valuable nutrients, organic compost provides many benefits to growing systems, such as nutrients, organic matter, and water saving potential.

Moreover, LILA is thoughtfully designed to offer a seamless and continuous composting experience. Featuring dual chambers, it allows users to compost waste efficiently—while one chamber is actively processing organic material, the other is curing, ensuring a steady supply of ready-to-use compost. This innovative system eliminates the need for downtime, making it easy to compost consistently. Additionally, the LILA Composter is equipped with an advanced odor elimination system that effectively minimizes smells, making it ideal for kitchens or small spaces, where space and odor control are crucial. These user-centric features make the LILA Composter a simple, accessible, and highly effective solution for anyone looking to make a tangible environmental impact.”

Are there specific engineering challenges you can speak to that the tools in your Siemens Xcelerator for Startups program package helped you with?

“Siemens’ NX tools were crucial in overcoming several engineering challenges during the development of the LILA Composter. NX’s seamless handling of organic surfaces enabled us to design complex, freeform shapes for the dual-chamber system and aeration mechanisms without glitches, ensuring smooth and precise modeling. The advanced design capabilities of NX streamlined the creation of complex mechanical components, improving efficiency and precision. NX also excelled in large assembly management, allowing us to efficiently manage the composter’s many parts and reduce processing delays. Finally, NX’s proven stability ensured reliable performance, even with intricate designs, helping us focus on refining the product without interruptions.”

Learn more

VCycene

VCycene is committed to not only tackling the problem of household waste, but also adding value to the environment. Their innovative system provides a sustainable solution to outsmarting organic food waste at home, with significantly lower energy usage and no air filtration maintenance required. Learn more here.

Siemens Xcelerator for Startups: Design and Simulation

At Siemens, we understand the struggles of early-stage startups. Let us remove the barriers on your startup journey by helping you transform your engineering ideas into real, marketable products with industry-leading software solutions. Join the Siemens Xcelerator for Startups: Design & Simulation program and grow your startup to its full potential. Want to get in touch? Reach out here.

VentureLAB

ventureLAB stands at the forefront of innovation where artificial intelligence meets hardware, uniquely positioned to lead in the commercialization of AI-driven technologies. By combining expertise in semiconductors and hardware development with cutting-edge AI, we empower startups to build scalable, high-performance solutions for industrial applications. We accelerate the convergence of AI and hardware to drive breakthroughs in manufacturing, healthcare, and transportation. Learn more here.

Maya HTT

Maya HTT is a leading software developer and engineering services provider, and a top Siemens partner. Every day, they help clients worldwide innovate to tackle today’s most complex engineering and business problems. Learn more here.