Carinthia University of Applied Sciences provides future microchip design engineers with holistic problem-solving skills

In order to prepare students for real-world engineering, academia must collaborate with industry to provide hands-on learning and experience. One university that has benefitted from bridging the gap between industry and academia is the Carinthia University of Applied Sciences (CUAS), which makes important contributions to transforming broad theoretical knowledge into practical applications. At its campuses in Feldkirchen, Klagenfurt, Spittal and Villach, Austria, CUAS provides its students with an international education in close cooperation with business and science disciplines that prepares them for future challenges. Within the field of digitalization, their faculty of Engineering and Information Technology collaborates with players from industry, research, academia, and government to develop and position the Austrian electronics and microelectronics sector internationally. With their strong focus on future-oriented technology, CUAS prepares students in the systems engineering bachelor’s degree program to apply system-oriented thinking as a key enabler of effective problem-solving and efficient product development. Read more to learn about how CUAS uses Siemens EDA to enable students to master complex semiconductor design!

Microchips for the future

For about five decades, integrated circuits (IC) have been the key technology for electronic systems in many application areas, ranging from data processing to telecommunications and automotive electronics. In the automotive domain, there has been amazing progress since the assembly of the first planar ICs in 1961 to today’s integrated processor components that integrate several billion transistors on a single chip. But the overwhelming complexity of such solutions brings new challenges in the design of integrated systems and circuits. Among these are modeling on different levels of abstraction, system-level verification, low-power design, circuit design in new technologies, high-frequency circuits, intelligent solutions for power electronics and an increase in design efficiency. CUAS is among the few educational institutions in Europe to offer a master’s degree in integrated systems and circuits design (ISCD), which provides the students with the necessary knowledge to master these challenges.

The Integrated Systems and Circuits Design course

The ISCD course at CUAS includes intensive theoretical and practical education for the modeling and design of integrated systems and circuits. There is a strong focus on analog and mixed-signal integrated circuits for sensor frontends and system-on-chip (SoC) design and system-in-package (SiP) integration. ICSD is unique among master’s programs worldwide because students’ training and laboratory work is supported by a three-semester IC design project. As Dr. Johannes Sturm, head of the integrated systems and circuit design degree program, explains: “Our students create their own integrated circuit, performing all the required steps from requirement specification to design and verification to prototype chip production and test. This makes them knowledgeable about all stages of IC design, so they are less prone to fall into the traps.”

From printed circuit board design to semiconductor verification

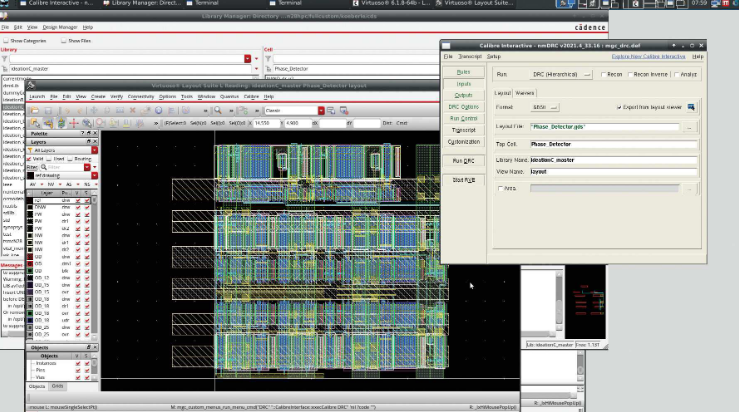

In the second part of the ICSD course, CUAS students specializing in electronics use PADS software for printed circuit board (PCB) design. This is one of the electronic design automation (EDA) solutions that is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services. Students also utilize other Siemens EDA solutions, such as Calibre software for their IC design projects. Calibre design solutions are leading industry tools for IC physical verification, delivering a complete verification and design for manufacturability (DFM) optimization EDA platform.

Using Calibre makes it easy to master the rapidly increasing complexity of integrated circuitry.

Dr. Michael Köberle, professor of computer-aided very large scale integration (VLSI) design at CUAS

Taking chip design to a higher level

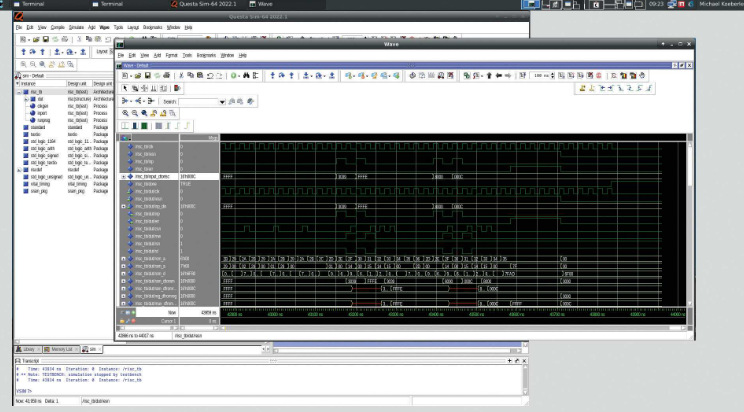

During the second semester, students also learn how to integrate mixed-signal VHSIC Hardware Description Language (VHDL) Designs, deploying digital simulation to the analog circuitry. They utilize Questa™ software from Siemens EDA, a functional verification solution that unifies a broad arsenal of verification solutions to tackle the growing size and complexity of SoC designs.

By integrating powerful analyzing and debugging functionality for the embedded software, Questa is clearly the best solution compared to all other tools I am familiar with on the market.

Dr. Michael Köberle

CUAS students and professors also benefit from the verification academy, a collection of free online courses provided by Siemens EDA. For instance, when CUAS started an initiative to implement top-level modeling for full-custom IC design, one of the aims was to seamlessly unify SoC designs with digital and analog portions as well as embedded computing. To this end, they utilized Catapult software, which they were able to start using within a matter of days thanks to the free on-demand training Siemens EDA provided.

Using Catapult, we can extend our curriculum with courses in system and chip architecture using the latest software tools. This is key to fulfilling our role, providing the semiconductor industry with the knowledgeable experts it so dearly needs.

Wolfgang Scherr, head of research group for modeling and design of integrated systems and circuits at CUAS

Read more about the Carinthia University of Applied Sciences

With the help of Siemens software, CUAS prepares engineering students to enter the world of industry equipped with firsthand knowledge of real-world tools and solutions. By bridging the gap between industry and academia, CUAS and Siemens enable students to tackle real problems and usher in a new era of innovation. To learn more about CUAS, read more about this case study here.