Associazione Liutaria Italiana uses Siemens software to unveil the secrets of violins

Genoa, Italy

By : Hannah Straub

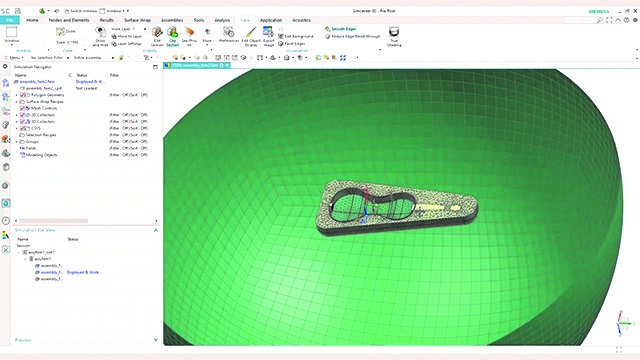

In a world of innovation, software can introduce concepts in technology that weren’t discoverable before, even when it comes to musical instruments. According to professors at Associazione Liutaria Italiana, the shape, form, varnish, and age of an instrument can dictate the sound, and it’s important to know the characteristics in order to construct a good replica.

“This is why our work with Simcenter and Siemens is so useful,” Professor Enrico Ravina, a professor of the Polytechnic School at Associazione Liutaria Italiana.

Associazione Liutaria Italiana is a cultural association that binds together musical instrument makers, researchers and musicians to provide cultural and technical assistance to preserve the musical instruments’ heritage and advance future development.

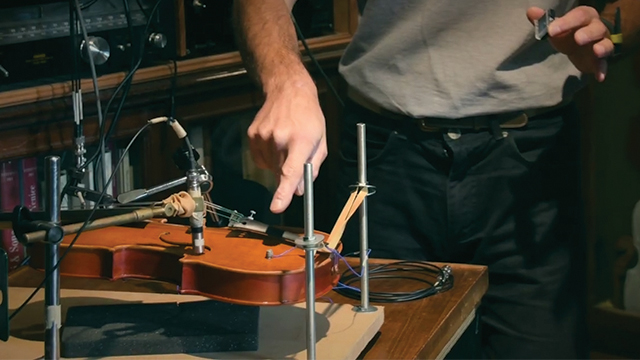

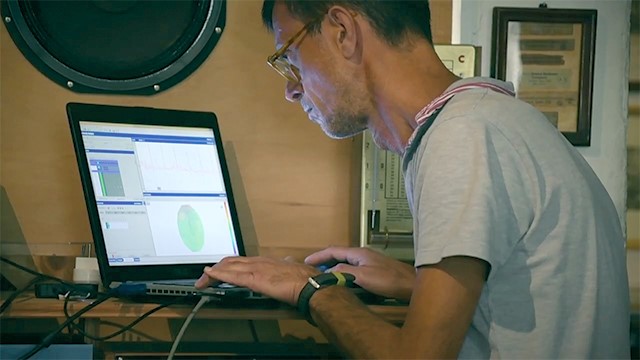

Professor Enrico Ravina and engineer Paolo Sivestri have been studying the acoustic performance of violins and other string instruments for over a decade, using a variety of Simcenter software simulation and testing tools to explore the data behind the sound. Master violin maker, Pio Montanari, recently joined the research project to gain insight into the construction process. Shortly after, Pier Domenico Sommati, second principal violinsit at the Genoa Opera also joined the team. Although not researchers, both Montanari and Sommati possess the valuable hands-on experience to help pinpoint what this novel research work will mean for the future of violinmaking and violinists around the world.

“For more than a decade, tools like Simcenter Testlab software and Simcenter SCADAS hardware have been very useful to study an instrument’s behavior to gain information from a vibrational and an acoustic point of view,” says Ravina.

Some of the main goals of their case study include:

- Understand the acoustic performance of antique string music instruments

- Identify the main performance contributors

- Provide violin makers with engineering insights on how to improve current instrument production

The researchers collected acoustic data precisely and performed detailed acoustic analysis while working with integrated software solutions and supporting the digital twin concept. They also used versatile testing solutions and enabled customized setups.

As a result, the men were able to provide data to explore and optimize new musical instrument designs, delivered information to help recreate instruments precisely with the same acoustic performance, and we able to conduct acoustic measurements onsite.

To read the full case study, click here.