Aalen UAS uses NX and Teamcenter in problem-based projects to prepare students for complex software environments

Educating future engineers

The city of Aalen, Germany is located in a region that hosts a cluster of industries such as pulp and paper, machine tools, and leading car manufacturers. These sectors demand engineers skilled in modern methods and software tools to quickly develop high-quality products. Founded in 1963 and upgraded to a university of applied sciences in 1971, Aalen University of Applied Sciences (Aalen UAS) is integral to the region’s economic success. Partnering with over 100 companies worldwide, the university specializes in applied research, focusing on IT security, autonomous driving, artificial intelligence, industrial automation, renewable energy, photonics and robotics.

Aalen UAS incorporates Siemens Digital Industries Software solutions like NX and Teamcenter into its practice-oriented study programs. Dr. Thomas Weidner, professor of digital product design, integrates these tools into mechanical engineering courses at both the bachelor’s and master’s levels, preparing students to meet industry demands.

Introducing students to PLM

The seven-semester bachelor’s course “Mechanical Engineering/Development: Design and Simulation” at Aalen University allows students to specialize in technical design, simulation, or vehicle technology after their first year. The course links industrial design with engineering skills, enabling its graduates to be fluent in the languages of industrial and product designers.

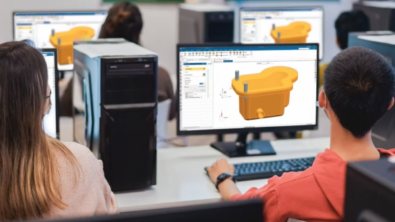

Students begin the first semester of the mechanical engineering course by learning freehand sketching for technical and design communication. Over the next six semesters, they undertake a comprehensive project focused on using NX for CAD to develop 3D models of a gearbox and its components, drawing from “NX for Beginners” resources. The curriculum includes a thorough introduction to product data management (PDM) systems in the initial four weeks, followed by practical application throughout the gearbox design process. This involves using NX for designing, modifying parts, and creating assemblies, while leveraging Teamcenter for managing CAD data, non-technical information, approval workflows, and revisions.

Covering the entire product origination process

For their initial exam, students at Aalen University import a full 3D model into Teamcenter where they analyze and correct any flaws in the product structure. They then create non-CAD presentation slides to detail the modifications. Utilizing Teamcenter’s workflow mechanisms, they assign these changes to document revisions and seek approval. Following the exam, students engage in a hands-on project to design products like radio-controlled cars, drones, or industrial robots entirely from scratch. This project culminates in the production phase using additive manufacturing. Working in teams based on their chosen specialization, students undertake the complete product development process.

“Using Siemens software, our students tackle product design tasks well beyond modeling particular parts and assemblies,” says Weidner. “From day one of their master’s courses, we teach them model-based systems design that covers a wide range of requirements.”

Designing a configurable robot

Following four weeks of PDM theory lectures and practical exercises, students are tasked with designing a 4-axis robot. Using NX, they construct a 150 percent scale model of the robot and design approximately one-third of its 191 parts, with half being standard components like screws and one-sixth purchased parts. After a quality review, students engage in variant management using Teamcenter to capture and assign features to the product line, resulting in a variant matrix offering 16 configurations. They then define configuration rules using Teamcenter and NX, both part of Siemens’ Xcelerator platform, to link features and rules and finalize the robot’s configuration.

Given the robot’s mechatronic nature, students integrate 16 software code sets into the design as CAD files, ensuring each configured robot’s bill-of-materials (BOM) automatically includes the correct software. This integration of PDM with enterprise resource management software ensures seamless shipment of configured products with appropriate software, minimizing additional manual work.

Understanding digitalized industry

Weidner emphasizes developing versatile professionals at Aalen UAS who understand and can manage digital processes across product design and production. Graduates possess interdisciplinary skills in data acquisition, system networking, cybersecurity, and data analysis for optimization, complementing their mechanical engineering foundation. This prepares them to navigate and contribute effectively in today’s digitalized industries. “Our students learn much more than just classical mechanical engineering,” Weidner concludes. “With a deep understanding of all industry requirements and the ability to use cutting-edge software like NX and Teamcenter to fulfill these needs in a holistic way, these graduates are the systems designers our industry so desperately needs.”

Interested in learning more? Click here for the full case study.

Click here for more information about how Siemens is empowering education and startups.

Comments

Leave a Reply

You must be logged in to post a comment.

This perspective is both fresh and engaging, encouraging deeper reflection on the topic. Area Code