This article was originally posted in @Simcenter Blog by @Adolique

In this first episode of our series of interview with our interns “3 Q&A with … ” Antoine explains us how, during his 6-month internship, he focused on the fuel cell topic which figures prominently in the automotive industry priorities, as illustrated by the recent joint venture between the French leaders Faurecia and Michelin

3 Q&A with Antoine Lepoil | |||

|

| Antoine Lepoil INSA Lyon, France 6-month intern Software: Simcenter Amesim Internship topic: modeling a proton exchange membrane fuel cell (PEMFC) within Simcenter Amesim. | ||

[SimcenterCommunity] | What’s your major for graduation in your engineering school? | ||

Antoine Lepoil: I joined the mechanical department at the INSA (Institut national des sciences appliquées) and will graduate in July 2019. There, I have been studying fluid mechanics, heat and matter transfers, thermodynamics, dynamic/cinematic of mechanical systems, rheology, hydrodynamic lubrication, acoustic and vibrations. Moreover, I got specialized in “Modeling and experiments”, meaning I received theoretical lessons about digital resolution methods, finite element method and learn how to use engineering software. To put my knowledge into practice about simulation, I led a 4-month team project consisting of designing the digital twin of a trebuchet and building a prototype of what we have modeled to compare simulation results to the real performance results. This was interesting because we were totally free to build any type of trebuchet. The unique requirements were: 1) use ten one-meter wood sticks to build it maximum 2) ensure that the initial drop point does not exceed 1m Simulation enabled us to predict a range of 19 meters and we reached 17 meters during our test phase, meaning we were 90% accurate on our prediction. We assumed that difference was due to friction from the system – a parameter we neglected in our simulation.

| |||

[SimcenterCommunity] | What has been your topic of study during those last 6 months? | ||

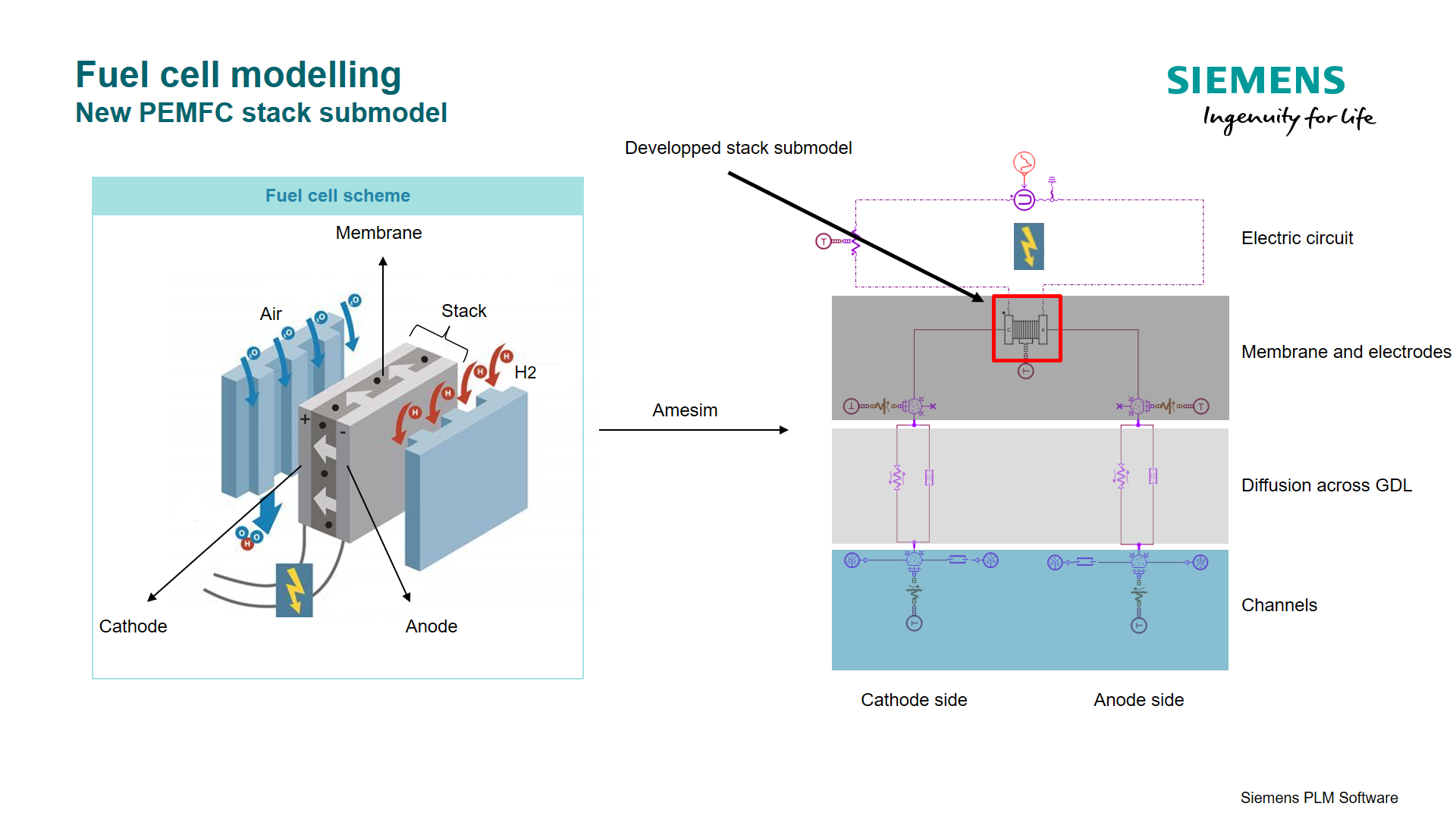

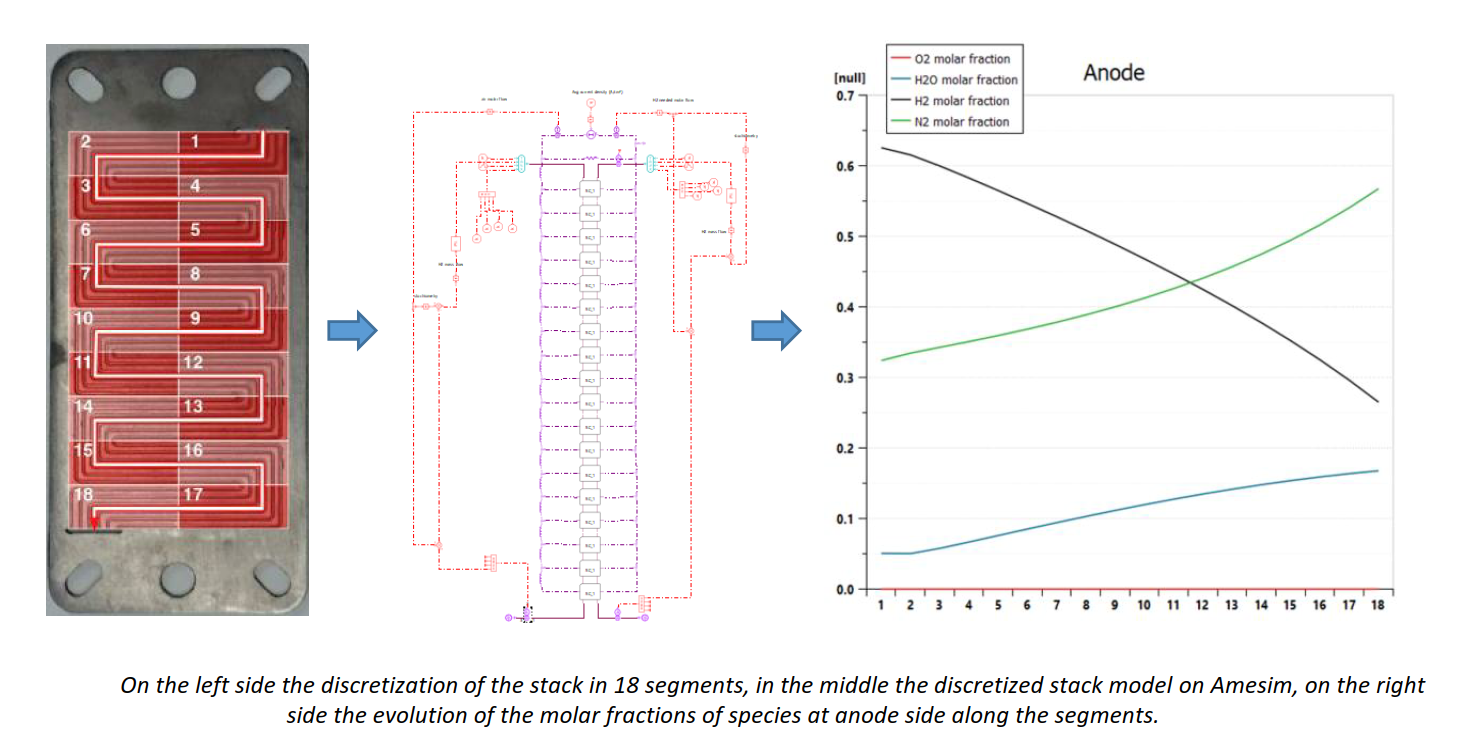

A.L.: I have joined Siemens PLM and the Simulation and Testing Division for a 6-month internship, where I focused on the fuel cell topic. Concretely, I worked on modeling a proton exchange membrane fuel cell (PEMFC) within Simcenter Amesim. So far, what’s possible in modeling a fuel cell with Simcenter Amesim is either with a simple PEMFC submodel reading a 1D table or with the electro-chemistry library that can be complex to use for new users. So, I built a new PEMFC model at an intermediate level of complexity, using physical equations we can find in the literature. Also, I made a Python application within Simcenter Amesim to help our users to parameterize the new fuel cell stack model, aiming to provide them with a new user-friendly interface.

| Fuel Cell milestones in industry:1839: Sir William Grove discovered the principle of producing electricity from an electrochemical reaction between hydrogen and air.1950’: General Electric’s Willard Grubb and Leonard Niedrach produced the first hydrogen-and-oxygen fuelled, proton-exchange membrane (PEM) fuel cell, the type used in almost all automotive applications.Pratt & Whitney’s model 304 jet engine using liquid hydrogen as fuel tested for the first time as part of the Lockheed CL-400 Suntan project1966: General Motors presents Electrovan, the world’s first fuel cell automobile.2016: Toyota releases its first hydrogen fuel cell car, the Mirai2019: Faurecia and Michelin to create a global leader in hydrogen mobility | ||

It was my first time using the software Simcenter Amesim. My first impression was that it is a powerful software with a variety of physics and made of an interactive and nice to use graphical interface, especially that there is a logic to understand in the process before simulating what I want. Also, I had the chance to learn in the software development center here in Lyon, France. So, I have been able to interact with developers and product managers and thus quickly and deeply master Simcenter Amesim. | |||

| |||

[SimcenterCommunity] | Getting the right skills and be ready for your first job, what are your thoughts about that? | ||

A.L.: My academic background allowed me to acquire simulation skills. My experience here working on Simcenter Amesim gave me more insight on what is behind simulation. Meaning, I now better understand how to gradually build a model and be aware of the hypothesis or simplifications that can be done to simulate a system. I’ve realized over my 6-month internship that there are some levels of simulation and each level directly impacts on the simulation time. This is an important parameter to consider when we try to build more complex systems or when we use it in real time. So, with an advanced-experience, I’ve better understood how complex the model should be to obtain good results.

Simulation is widely used in every kind of industries, aeronautic, automobile, trains, power plants… So even if I think that for a recruiter any type of skills is important, today, I see a lot of job offers in which simulation skills are required. Well, of course, it is always possible to gradually learn how to use software, nevertheless already mastering simulation software’s is an added-value. | |||

What to read next:

Guidance for Academia

Guidance for Academia