Benefiting from transformative learning

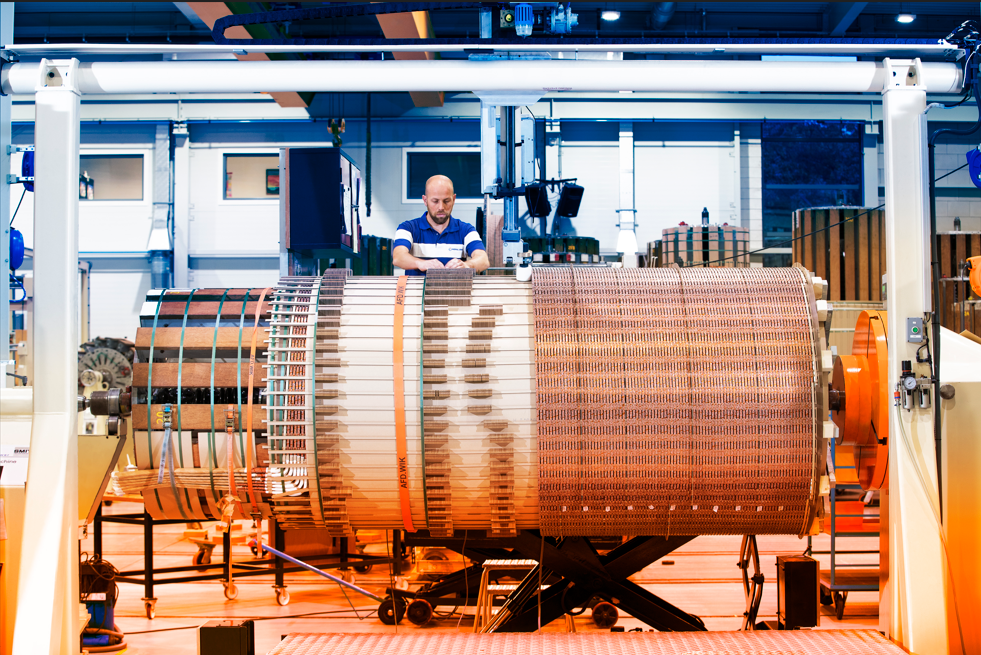

Royal SMIT uses NX and the Siemens Xcelerator Academy to improve its digital transformation

Shifting toward digital transformation

The increasing demand for innovative and sustainable electrical components is essential for powering homes, businesses and cities around the world. To accomplish this, manufacturers must transform their processes and deliver technologies that are efficient and environmentally friendly. However, this goal includes challenges such as integrating new technologies, meeting stringent environmental standards and responding to rapidly changing market needs.

Royal SMIT Transformers B.V. (Royal SMIT) is part of the SGB-SMIT Group and has been building transformers, from large power and specialized transformers to shunt reactors and phase shifters, since 1913. These transformers are critical for supplying power to cities, industries and millions of households. With an eye to the future, Royal SMIT aims to continue honing its craft as a market leader in developing, producing, selling and maintaining large power transformers and their installations. Accomplishing this goal requires digital transformation and investment in learning programs that focus on blending technical expertise with eco-friendly practices.

To achieve this, Royal SMIT teamed up with Siemens Digital Industries Software to leverage NX™ software and the Siemens Xcelerator Academy, which are part of the Siemens Xcelerator business platform of software, hardware and services.

Addressing integration challenges

When Royal SMIT transitioned to a new version of NX in late 2023, the change was more disruptive than the company expected. One challenge was getting engineers up-to-speed with the new version. Since they were used to the previous version, they were struggling with unfamiliar features and workflows, especially for handling assembly constraints and drafting.

“Migrating to a new NX version brought significant changes,” says Maikel Peeters, manager of mechanical engineering at Royal SMIT. “Our engineers were used to the old way of working, and the new version introduced new functionalities and workflows. This led to uncertainty, frustration and a decline in productivity.”

Leveraging a structured learning program

To address these challenges, Royal SMIT leveraged the Siemens Xcelerator Academy, which is the essential and sole learning platform designed for learning and enhancing proficiency with Siemens software. It guides users through the complexities of digital transformation via a diverse range of training solutions. With comprehensive learning programs, flexible learning memberships and live training available online and on site, the academy helps users confidently navigate and adapt to the evolving landscape of digital transformation.

In collaboration with the Siemens Xcelerator Academy, Royal SMIT launched a comprehensive training initiative to help its engineers overcome their stressors and learn the new system.

“The main goal of this training program was to eliminate frustration among the engineers by guiding them through the new features and associated workflows in NX,” says Peeters. “By fostering greater understanding and skill, we aimed to increase job satisfaction. A pleasant work environment where engineers feel in control of their tools directly contributes to higher productivity.”

Using customized coaching and learning plans, this initiative aimed to rebuild confidence and competence and was built around three core components:

1) An NX modeling game, which is a diagnostic tool for assessing the user’s current knowledge and identify pain points. This component was essential for understanding the issues engineers were having and influenced the next two components.

2) An interactive sketch training that focuses on the new sketching tool and standard settings.

3) NX design workshops based on real-world issues that engineers submit and include tips, tricks and new methods.

To ensure these programs were successful, Royal SMIT delivered these training components via small groups (eight to ten participants) via live, on-site training, providing hands-on engagement and a practical learning environment.

Empowering engineers

Due to the Siemens Xcelerator Academy workshops and interactive training, Royal SMIT was able to overcome the hurdles of digital transformation. After undergoing the customized training, engineers could now confidently navigate NX more efficiently, encountering fewer roadblocks when accomplishing daily tasks; thus, improving productivity and employee satisfaction.

“Before the training, some colleagues literally had to take a walk to cool down their frustrations, which hasn’t happened since,” says Peeters. “Thanks to the program, our engineers now have more knowledge of the new capabilities within NX. As a result, they encounter fewer obstacles in their daily work. This directly leads to less frustration and a smoother workflow. Engineers can now better focus on their core tasks without being distracted by technical issues.”

Overall, this training initiative led to engineers reporting fewer unresolved issues in their daily workflows and an observable application of new skills.

To continue empowering its engineers, Royal SMIT appointed key users from each engineering discipline to shape the workshops, ensuring they are equipped to lead future sessions independently. By actively involving engineers with designing the program, the company can increase the training’s effectiveness, relevance and chance of successful implementation in the future.

Authors: Luuk Huizer, Cristiana Cerrato Accomazzo