How long can you expect a PCB to last? Try digitalization to find out!

People expect that when they step into a vehicle, they will be able to safely get to their next destination with no issues. This will be even more critical for automakers to guarantee as autonomous and electric vehicles are released into the market, because people likely won’t be behind the steering wheel.

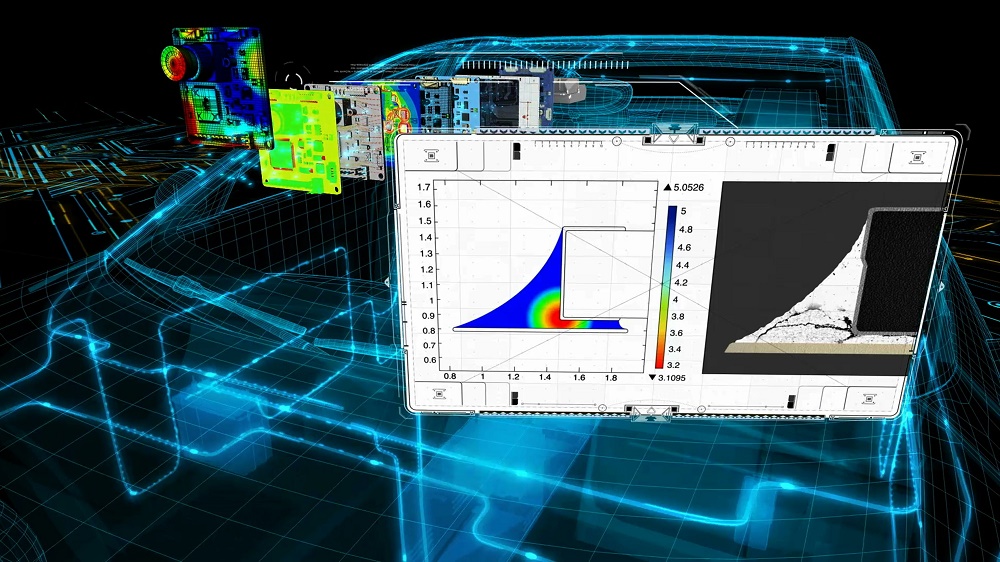

The processes automakers have in place right now are fine, but they won’t be robust enough to ensure these new vehicles will be able to efficiently, and safely, get customers to their destinations. We’ve looked through many PCB failure analysis techniques and, even though there are many factors automakers must address, there’s one final step they must consider after completing their stress studies.

After all the PCB failure analysis techniques have been applied and stress studies are completed, so what? How do you use this information?

Assuming that the solder joint stress does not surpass ultimate strength and fail on the first power up and vibration, it will take time for the cracks to form and propagate. The first question is, are the stresses below the endurance limit? Can we be sure it won’t crack or fatigue? It the stress is above the endurance limit, it then is a matter of time until the crack occurs, if so how long will it take to fail?

Given enough time, most everything will degrade. However, if a crack takes 100 years to result in a failure, that can be considered acceptable. This process is performed in all engineering industries.

Also, many electronic system components and materials have not been investigated to this level of detail. Fatigue assessments don’t exist to quantify life expectancy, and are further complicated by the solder being reformulated to remove or reduce levels of lead due to regulatory pressures and requirements. Material fatigue characterization often lags in such situations, and inhibits accurate forecasts of life expectancy. This is a typical issue in the industry as fatigue testing of new materials takes time and considerable costs.

In response, the industry has developed PCB failure analysis techniques and utilized general risk factors assessments and empirical knowledge to guide development. While they are useful, it often results in overdesigned products to achieve design and safety margins. As the digitalization and simulation capabilities for electronic systems improve as required by the next generation of vehicle development, the industry will demand these new material properties – there will be no choice.

The future of AV/EV/ADAS is exciting, but the engineering challenges are ever escalating. The digitalization of PCB failure analysis will play a key role now that the safety and robustness of electronic systems and their circuit boards is front and center. It is no longer a matter of customer frustration, but of customer safety. The glitchy consumer electronics functionality of the past cannot be allowed to continue. As was determined during the Apollo 13 mission – failure is not an option.

This concludes the final article of our series on electronics systems and the challenges to provide solutions for products of the future. If you wish to start from part 1, please click here:

About the author

Greg Roth is the director of automotive and transportation solutions in the Industries Group at Siemens PLM Software. In his current role, he champions CAD, CAE & PLM technologies and processes for companies at a global enterprise level so they can achieve substantial reductions in product development costs and time while improving overall quality. He previously held positions at Ford Motor Company, Eaton Corporation and Amcor Packaging. He was also chief engineer for the CAE and NVH departments at ZF-TRW Automotive North America Braking Systems in Livonia, Michigan. Greg holds an master’s degree in mechanical engineering from the University of Michigan, a master’s degree in electronics and computer controls engineering from Wayne State University and a bachelor’s degree in mechanical engineering from Michigan State University.