Siemens and IBM collaborate to help companies accelerate product development

Delivering today’s highly complex products can be more difficult than ever.

Smart, connected products are increasingly more complicated due to a proliferation of embedded software, microprocessor-based controls, and electronics systems. The scope of electronics and software in products is changing product design, development, and manufacturing for many industries. Market demands and regulations are creating more sustainability requirements for businesses as well. As organizations look to meet the demand for more complicated products as well as support compliance objectives, they need a framework that enables them to “design-in” sustainability and performance while offering transparency across the entire product and asset lifecycle.

Added complexity is not the only hurdle. Businesses want to deliver this next generation of smart products “at half the cost in half the time.” And they often need to do this – and more – with fewer resources to meet energy efficiency targets and carbon limits and reduce demand on materials. To help our customers prepare for these growing requirements from the beginning, Siemens Digital Industries Software and IBM are expanding their long-term partnership to collaborate on the development of a new software solution. The goal is to create a solution integrating systems engineering, robust Product Lifecycle Management (PLM) solutions, true multi-domain optimization, and asset management to help organizations optimize across the entire operational lifecycle of their products.

Meeting evolving product needs

The idea of complexity is not new. What is changing is that the products are getting smarter and more connected than ever. The expected functionality in products requires increased levels of electronics systems and the software to run them. As a result, we are witnessing that companies are spending an increasingly greater percentage of their program schedules at a significant cost integrating software, electronics, electrical, and mechanical systems to work together. This can be challenging to companies, as they may need to reevaluate their processes and procedures across the entire product lifecycle.

Early conceptual design is often the groundwork for a successful product. Defining the requirements for success, the stakeholders of the project, customer demands, and much more – create the design space for the project. And the decisions made this early on can have an outsized impact on the overall cost, performance, and sustainability of a product.

The level of detail required for system-of-systems relationships is expanding. It is driving the need to quickly evolve the way engineering domains interact. The ever-increasing scope of software in products needs to be defined earlier. And it should be connected and managed across the life of the products. To develop highly complex, software-driven products faster and reduce risk while staying on budget – developers/manufacturers must do more than shift. They must LEAP.

Today, visibility often comes too late in the process – when making changes is more expensive and when program schedules are already under stress. Companies need a new way to determine earlier whether the systems – mechanical, electrical, electronics, and software – seamlessly work together.

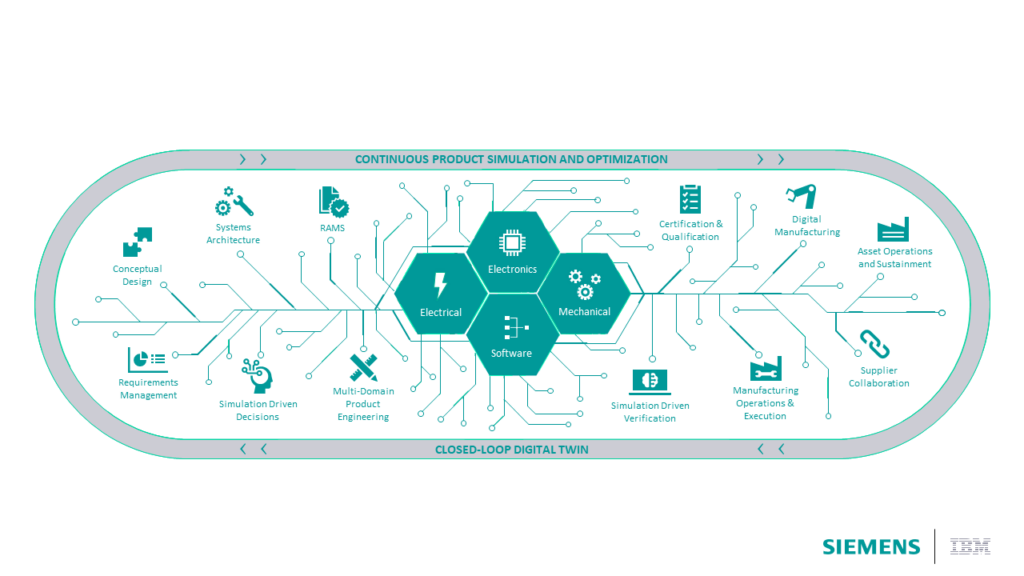

This new development model should enable modeling, prototyping, simulation, and verification/validation as early as possible in the product lifecycle. It should be leveraged from concept through operations. The solution should address multi-domain collaboration and accessibility across all levels of the business – electrical, mechanical, software, electronics, manufacturing, suppliers, logistics, and operation.

This holistic, standards-based, integrated approach to systems engineering should also be established with functional software development and verification capabilities for success. That starts with an intelligent systems-based front-end design. It requires continuous connection across the lifecycle to further break down the process silos. All to empower users to develop products faster with fewer resources across the full product lifecycle.

The environment should provide complete end-to-end traceability across all domains and disciplines, including electrical and software domains, providing continuous understanding on the impact of change and delivering the ability to respond and innovate faster by reusing data and systems. Product development today and in the future also requires that this advanced connectivity and traceability is extended across the entire product lifecycle, with the complete supply chain, and the extended enterprise.

Creating a closed loop from concept engineering through asset management

The Siemens/IBM collaboration is aimed at designing a solution to enable a holistic and continuous integration of systems design across the lifecycle that can make engineers’ day-to-day lives better by taking digital transformation and Model Based Systems Engineering (MBSE) to a new level.

The IBM/Siemens will work to create a complete and integrated multi-solution, multi-domain, standards-based environment.

This collaboration will seek to develop an environment to combine systems engineering models and requirements to develop and optimize the Electronics/Electrical (E/E) architecture, identifying possible implementation architectures. This in turn could spearhead the generation of detailed design proposals for embedded software, networks, electronics, and electrical wiring & harness designs. Engineers could then progress through the development lifecycle using interactive and generative design tools to produce an output thoroughly vetted by built-in validation & verification technology that could directly feed manufacturing and service. This environment could combine the respective development and production management tools from Siemens and IBM to offer data transparency and traceability where desired from product concept through production, to operation and maintenance.

At the front end of product design

One of the first steps in this design process will be Siemens taking the IBM® Engineering Systems Design Rhapsody® product and seeking to integrate it into the Siemens product process flow to help enable the creation of complex distributed systems as well as implementing the individual components directly. This strategy could enable connecting into a product’s functional and non-functional requirements and detailed systems engineering breakdown.

The Siemens/IBM solution is being designed to help businesses achieve faster results and optimized solutions, across all product domains, delivered through an integrated flow across applications, with a new level of interconnectedness, easily crossing organizational boundaries. Our collaboration could help departments and development organizations who historically were disconnected, to collaborate and address the challenges of the new development imperatives for creating modern products.

Our goal is to help manufacturers to “design-in” sustainability, innovate faster, and connect from concept through operations.

At the asset operations and sustainment stage

Service lifecycle management can assist in maximizing business value for product serviceability by connecting service engineering to service maintenance and enable new collaborative processes between OEM and operators. Siemens and IBM collaboration will also focus on reuse and recycling of processes and materials to support traceability and product development for sustainability earlier in the design and engineering processes. This could foster rapid decision making while driving improvements in cost, performance, and sustainability. For instance, under-performing components or design elements that require excessive maintenance or early replacement could potentially be traced via the digital thread all the way back through production and development, allowing companies to do faster problem identification and remediation of the element design.

Complete simulation-driven systems and software engineering solution

The markets, products, and requirements of tomorrow’s business may be growing in complexity, but with the right digital solution, mastering complexity can become a company’s competitive advantage. The Siemens/IBM partnership aims to provide customers even stronger integrated, comprehensive, and connected system, software and MBSE solutions. And with it, businesses could gain a flow across applications and a new level of interconnectedness.

Continuous integration. Reduced rework. Quick delivery.

The future of solution development

Initially, we are working to connect IBM Engineering System Design Rhapsody for systems engineering and IBM Maximo Application Suite for asset management with Siemens’ Teamcenter® software for Product Lifecycle Management (PLM) and Capital™ software for electrical/electronic engineering from the Siemens Xcelerator portfolio of software and services. (Review IBM press release – Siemens and IBM Collaborate to Accelerate Sustainable Product Development and Operations)

We will also collaborate on developing a SysML v2 based solution with an associated migration path for customers to transition to the next generation Systems Lifecycle Management solutions. SysML supports the specification, analysis, design, verification and validation of a broad range of systems and systems-of-systems. Service lifecycle management can assist in maximizing business value for product serviceability by connecting service engineering to service maintenance to facilitate new collaborative processes between OEM and operators.

Helps manufacturers to “leap left” for continuous integration

across domains from concept through operation

For additional information about current Siemens and IBM offerings visit our respective websites – www.siemens.com and www.ibm.com.

Statements regarding IBM’s future direction and intent are subject to change or withdrawal without notice and represent goals and objectives only.

Comments

Leave a Reply

You must be logged in to post a comment.

Great news! IBM and Siemens have joined forces for the ELM Platform!

#IBM #ELM #Seimens