Sustainable energy and 3D printing

Energy and manufacturing are two highly interconnected industries in global economies. No energy generating device, be it wind, solar, nuclear, hydro, or fossil fuel can come into existence without some manufacturing process. And those manufacturing processes rely on energy inputs, through electricity, fuel combustion or even more direct application with geothermal heat or large water ways. It is safe to say neither would be possible without the other. Over time these two industries have grown together, getting more capability and complexity, and this continues today but the technologies are quite different from the first waterwheels in blacksmith shops. Additive manufacturing (AM) is a perfect example of this dynamic. Let’s talk about how AM is being deployed for the sustainable energy systems of tomorrow.

First, let’s examine my claim of why AM is the perfect example for the dynamic between manufacturing and energy generation. Additive and 3D printing processes, regardless of the technology rely heavily on electrical infrastructure. Desktop printers rely on resistive heaters for extrusion in fused filament fabrication (FFF/FDM) and stereolithography (SLA) requires light energy to alter the bonds of the plastics for solid structures. On the industrial side of AM, powder bed fusion (PBF) machines rely on intense laser beams to sinter the print materials together, the energy consumed in this process is why it is not always the best choice to print large components. The more AM is used in everyday application, the more electrical capacity is required in the grid. Fortunately, many of the applications of AM are within the energy industry, through repair processes and optimized component geometries for energy conversion. More efficient energy generation means more electricity is available for AM, leading to more efficient energy systems, in a self-reinforcing dynamic.

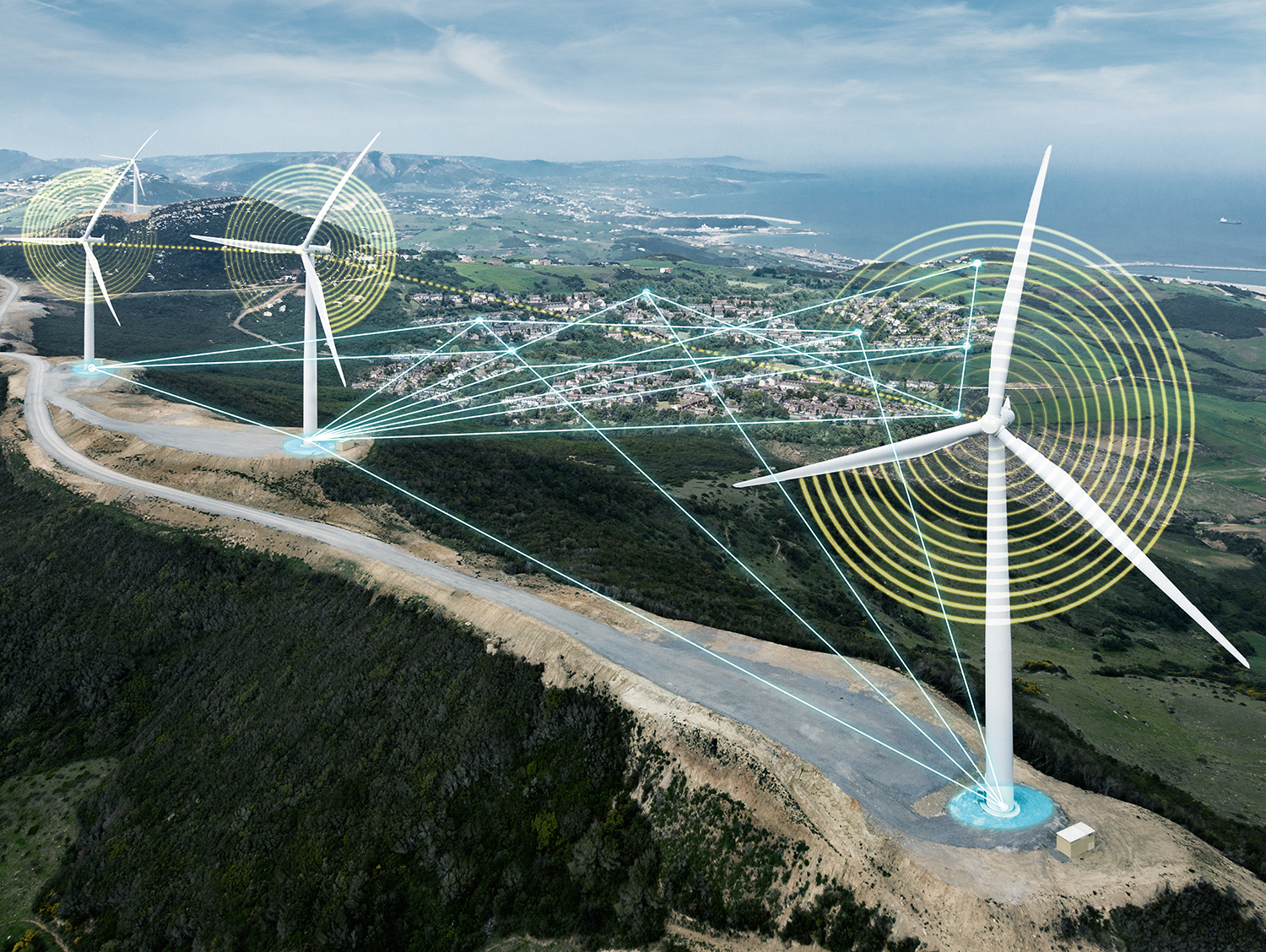

But what kinds of energy systems are adopting AM technologies to create this cycle of improvement, one might ask. Well, most of them. AM has early-stage implementations in the nuclear energy industry as I’ve talked about previously, it has been adopted by Siemens Energy for the large gas turbine blades to create near-perfect seals between the blades and the turbine wall, and it is even being used in wind turbine designs to reduce overall weight of these massive structures.

- In the Siemens Energy gas turbines, additive manufacturing is used for the replaceable blades inside the turbines. To extract the most rotational energy, and eventually electricity, for the combustion process the hot expanding gas cannot bypass the blades. Traditionally a turbine would have a new set installed based off of a single or maybe a handful of blade shapes to get a close fit between the blade tip and the turbine wall. But that is only so precise, and ass soon as the internal start to wear the efficiency drops because the blades are ground down or corroded. AM provides precision customization of each blade beach it does not rely on expensive molds, improving operating efficiency. It also removes the blade recycling process which consumes a great deal of energy to melt and reforge blades, with AM the damaged tips are ground down and re-printed and possibly with one of the customizations for its position.

- Wind turbines also benefit from additive parts, but in a very different way because wear is less of a problem in these systems. Instead, metal printing is used in the massive gears inside the wind turbine that increase the rotational velocity of the drive shaft to convert the wind’s force into electrical energy. But these massive gears take energy to get them spinning, which pulls energy away from the convertible pool, AM can be implemented to lightweight these parts while retaining their strength characteristics. This allows wind turbines to get more electricity from the wind they were already experiencing.

These are just a couple examples of how AM is making the energy industry more efficient and establishing the symbiotic relationship between energy and manufacturing. But is also impacts heat-based processes. In the energy industry, heat is possibly the most important form of energy after rotation – it is vital in thermal generators like nuclear, coal, or geo-thermal. AM optimized components can increase the transfer of heat dramatically by increasing surface area and reducing the total material that must be thermally saturated to move heat through a solid material like stainless steel. Heat is also important to manufacturing and finding methods for applying it in the sustainable manufacturing processes of tomorrow is critical.

- Some processes can rely on cheap renewable electricity for resistive heating as smaller 3D printers implement, but industrial-scale steelworks may not be satisfied by these technologies due to maximum temperature or scale limitations. Fuel will still need to be burned, using AM optimized burners the amount can be greatly reduced if it is traditional fossil fuels. But green hydrogen may also be an option, still requiring optimized fuel nozzles however because hydrogen gas is a much small molecules than hydrocarbons.

Whatever process is being optimized between the energy and manufacturing industries it is clear they will continue to keep an important relationship even as we transition towards a more environmentally sustainable, global economy. For some more information on what is happening in these two worlds, 3D Printing Industry has a great article on the topic. It covers some of Siemens’ advancements in the arena as well of some other folks in industry and academia. You may also be interested in listen to a conversation on the topic of energy and additive manufacturing with Ashley Eckhoff and two experts of our energy and utilities group – John Nixon and John Lusty.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow