Machine builders’ competitive edge: Product Lifecycle Management

Technology is changing at an exponential rate globally, causing customers to demand that manufacturers produce complex products of varying sizes, colors, materials with adherence to changing consumer demands. This dynamic environment places pressure on machine builders to engineer flexible and agile machines at a lower cost to remain competitive globally. Therefore, it is essential for machine builders to reduce margins and overdeliver on projects to be competitive, thus sometimes threatening their longevity and reducing staff confidence.

Digitalization – a culture of change

Machine builders must adopt a culture of change to keep their most exemplary employees, address global competition, and increase product complexity and profit margins. This change begins with digitalization. Machine builders use cloud-based solutions to track and manage complex customer requirements change requests and reuse data across projects to provide machines to market quicker. Through these modifications, machine builders can be aware of time, cost and resource savings.

Product Lifecycle Management (PLM) for machine builders provides the end-to-end solution tools to transform and optimize operations digitally.

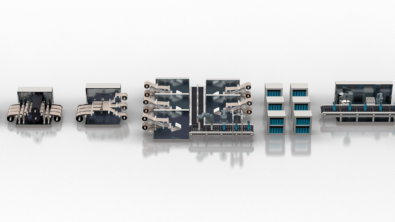

A holistic PLM solution allows machine builders to harness the power of a multi-disciplinary design, project management and an engineer a modular approach. By mastering these three domains, machine builders can satisfy customer requirements/reconfigure machines, increase collaboration and reuse data across departments to master global competition.

PLM for machine builders addresses silos, providing an integrated process to design and manage machine configurations.

High-quality machines with competitive performance

PLM provides features and performance that result in optimum machines with competitive differentiation. Design, project management and integrated workflow tools combine to a connected platform that offers predictable, productive machines that provide blended CTO, ETO functionality, project management and design management.

“Digital investments have generated value for industrial products organizations, with averages of 15 percent return on investment, 5 percent expense reduction, 4 percent increase in revenues and a 62-day reduction in time to market for new products/services.” – IBM Institute for Business Value, “Digital transformation at scale for industrial products.”

Using PLM tools that are secure, modern and scalable helps machine builders realize a culture of change that reduces costs, saves time and optimizes resources. PLM is configured with industry best practices, providing machine builders with an instant-on, cloud-based solution for improved design collaboration efficiency, reusing project data to deliver products faster. Also, it implements real-time dashboards to circumvent delays and leverage modular engineering approaches to automate and streamline repetitive tasks.

Learn more benefits of Siemens PLM for machine builders.

Siemens’ software solutions

Siemens’ Xcelerator portfolio helps companies of all sizes create and leverage digital twins that provide organizations with new insights, opportunities, and automation levels to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – where today meets tomorrow