Research Collaborations – Siemens Digital Industries

Siemens believes that an approach of openness and cooperation, guarantees long-term commercial success.

“If I have seen further,” Newton said as early as the 17th century, “it is by standing on the shoulders of Giants.” Global multi-national giant Siemens AG, also believes that an approach of openness and cooperation, guarantees both long-term commercial success and the common good. Thousands of Siemens engineers and researchers around the world collaborate on the research front with universities, research institutes and other commercial companies. In the last decade, Siemens has expanded its operations in Israel, particularly in the field of smart industry and the smart factory. Previous article in this series focused on commercial collaborations with startups through Siemens’ open innovation program Siemens Dynamo. In this article, we want to focus the lens on the field of research collaborations.

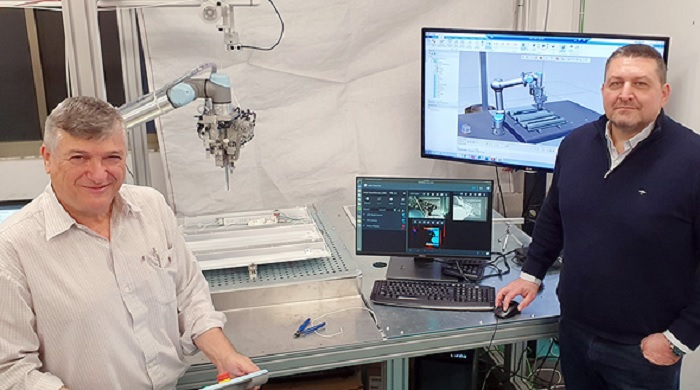

Robotics in Industry Research Consortium – at the initiative of the Israeli Innovation Authority

In 2019, Siemens Industry Software in Israel joined a consortium in the field of industrial robotics sponsored by the Israeli Innovation Authority. The consortium model enables industrial companies to team up with top academic research groups to develop state of the art technologies for manufacturers in Israel and around the world. This specific consortium deals with the use of robots to perform assembly jobs with flexible deformable components: cables, pipes, gaskets, etc. Operating with components that can stretch, deform, and entangle in space is one of the most challenging domains for robotic systems. Siemens software 3D simulation tools enable to train and validate the developed robotic systems using machine learning and a physical model of reality. Omer Einav, chairman of the consortium and CEO of Polygon, emphasizes: “The technological breakthrough carried out in the consortium will enable efficiency in the mechanical and electrical design of the robotic systems, and will also accelerate the commissioning phase. “

Joint research with CIVAN in the field of green laser as part of the EUREKA program

In 2020, Siemens Technology joined a green laser research project with the Israeli company Civan Advanced Technology. Civan has a unique technology in the field of industrial laser, which allows control of the footprint and intensity of the laser beam. This capability makes it possible to adjust the laser beam to the required manufacturing operation, and to the type of metals used – copper in this study. Copper is a valuable material in the industrial world thanks to its high electrical conductivity and efficient heat transfer. Efficient heat transfer poses a challenge in the fine processing of copper, due in part to rapid dissolution, rapid cooling and sometimes even evaporation. The research is being carried out with other European partners within the framework of EUREKA, and its aim is to develop a system for industrial use, which enables the production of complex copper parts efficiently, and of uniform quality. Siemens’ mission is to test the technology from the point of view of the end manufacturer.

Innovation Authority Multinational Corporate Program: Siemens & Cybord

Another route offered by the Israel Innovation Authority to Israeli companies only is the R&D support route with multinational corporations. The model is based on the corporation’s broad international presence, and its deep familiarity with the target market. This year, Siemens’ first collaboration under this program was launched, with AI startup Cybord.

This is in fact an agreement between three partners, explains Tovy Yadin, director of electronics innovation at Siemens:

- Cybord has developed unique capabilities for detecting defects and counterfeits in electronic components through image processing and machine learning, including those that indicate an attempt to carry out cyber-attacks using the supply chain.

- Siemens Digital Industries Software, which already offers a leading solution for production management and material management in electronics manufacturing, and is interested in expanding the solution through the capabilities of Cybord

- The State of Israel through the Innovation Authority, a partner in financing, and contributing to the promotion of the project.

“In recent weeks, we have scanned millions of components at a shared customer site,” says Dr. Eyal Weiss, the founder and chief technology officer of Cybord. “In doing so, we have reduced the risk of malfunctions at the end customer, with all the implications involved in terms of costs and possible damage to reputation.”

Additional collaboration tracks with Siemens Digital Industries Software

As a commercial company, Siemens’ goal is to promote these research collaborations into commercial collaborations. At the same time, Siemens encourages innovative companies to turn directly to commercial cooperation, and offers several routes for this purpose, such as:

Siemens Dynamo – A convenient and unique entrance gate for companies that have a product that complements Siemens’ value proposition. So far, 11 start-ups have been selected to the program.

Siemens Frontier – a program for disruptive innovation startups that can expand the functionality of Siemens software in the fields of robotics, virtual and augmented reality, 3D printing and Artificial Intelligence. Two of the startups that joined the program in 2020 are:

• Castor3D – which has developed a decision support system that knows how to scan a complex mechanical product (BOM) and recommend parts and sub-systems that are suitable for 3D printing, including suggestions for customization in the design.

• Gileen – that has developed a geometric engine allowing the design, analysis and 3D printing of three-dimensional porous bodies (microstructures) in combination with heterogeneous materials.

Siemens Software & Technology Partner – A more advanced stage of commercial collaboration that enables the sale of a common product.

For Siemens Digital Industries, the goal of all these tracks is to always be at the forefront of technology, and to join hands with the “best and brightest” in the fields of the smart factory, in Israel, and in other technology centers around the world.