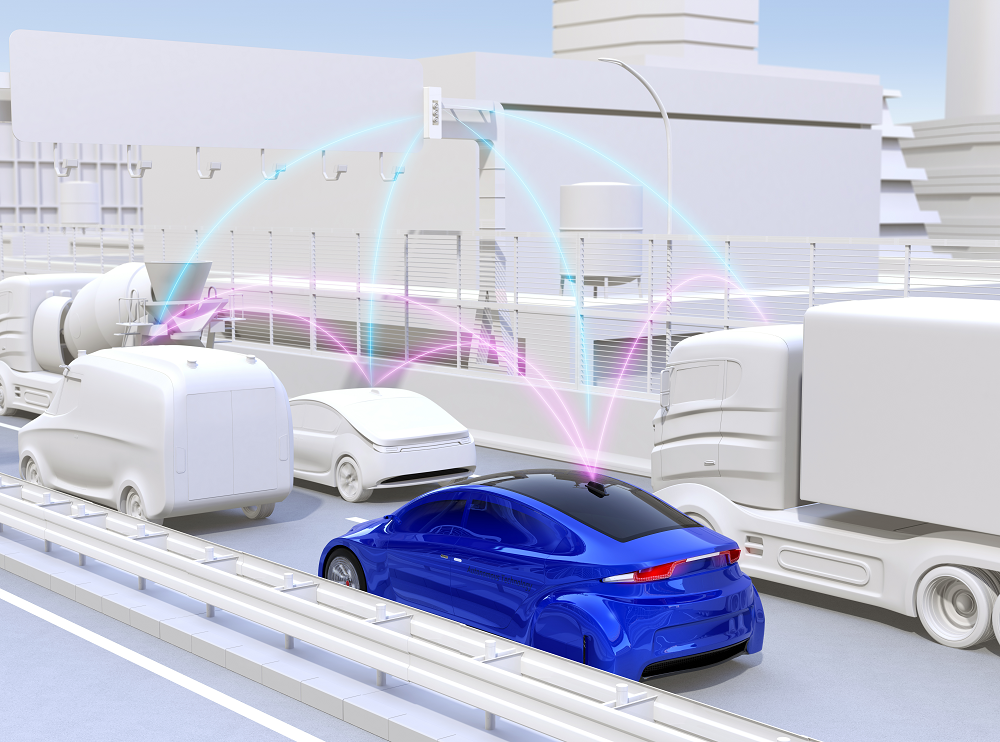

Software and hardware together in autonomous cars

Automotive companies are trying to figure out how software and hardware will work together in autonomous cars, and they want companies with electronic design automation experience to help them accomplish that.

One company that can offer guidance is a recent Siemens PLM Software acquisition, Mentor Graphics. I spoke with Andrew MacLeod, Mentor’s director of automotive marketing, to learn how Mentor thinks software and hardware could work together in autonomous cars.

When I spoke with MacLeod, I wanted to learn what the move toward automation means for the auto industry. We began by discussing the biggest challenges he sees the auto industry facing as automation expands. We then talked about what today’s biggest need for development is and how systems of systems could come into play.

I recently attended a seminar in Cambridge, Massachusetts which targeted AI and deep learning programmers and their managers. Of course there was talk about the inaccuracies and applicability of AI programming approaches, but a surprisingly consistent theme was “remember why you are creating the code” – that is, the end purpose of coding was more important than elegance of code.

MacLeod echoed a similar theme when he spoke about the need to manage a system of systems rather than individual systems. Making any one system better – for example, more powerful LIDAR, or elegant code in the master brain – is noteworthy, but not effective if the overall power consumption required to operate the vehicle has a negative effect on range and makes it undesirable to consumers.

This forces the adoption of a product development approach that can balance across subsystem needs, and more importantly, make it so sub-system engineers and developers can collaborate and speak a common language. Development of a new generation of technology combinations will only be cost-effective and satisfy market needs if it’s developed in conjunction with a new generation of design methods and processes.

As my conversation with MacLeod continued, we discussed the engineering culture in the auto industry, and the changes they will have to go through to ensure a successful development processes.

EDWARD BERNARDON: If you look at how development is done in many car companies, especially when working with the supply chain, there tends to be silos, like one for software another for hardware. To engineer a system of systems, those silos have to break down. Do you think it is as much an engineering culture change as everything else we’ve talked about?

ANDREW MACLEOD: I think so. And I think we are starting to see silos breaking down with many partnerships across the industry.

Nobody has everything to put together a complete, optimized, autonomous drive system. There have to be partnerships between hardware and software expertise, and the houses that can provide the right kinds of sensors, or the right kind of SoC [system on a chip] or microcontroller.

I think that as long as everybody can see a benefit and devote a vested interest, it is working to benefit the overall system, and partnerships is the way to go.

This would include talking about the way that we do development. Traditionally, we would have lots of physical car testing going on, and that was partly what contributed to the seven year development lifecycle of the vehicle, which we have to shrink.

Maybe with autonomous drive, some carmakers want to put LIDAR in the headlamps, for example, because the headlamp dims very quickly in a protected environment, but that introduces all kinds of thermal challenges, as an example.

Rather than running physical experiments and putting that physically in the car, measuring, adjusting, and so on, this whole concept of simulation and creating this digital twin – where we can run many, many simulations for thermal replacements and power consumption very quickly before any component goes anywhere near the vehicle – is going to be absolutely key in shrinking the car development cycle, because we can’t be running in seven year design cycles.

We can’t have the same hardware and software in a vehicle from day one to year ten. It doesn’t work.

Consumers are becoming very interested in the user interface of infotainment systems, for example. Consumers are looking for iPad elegance and are not happy to put up with a clunky interface. And that requires software updates over the lifetime of the vehicle.

This whole concept of simulation and being able to update the car, doing a lot more in software, less experiments – all of that kind of stuff – along with industry partnerships, I think is going to be the trend that we see in the future.

This concludes part three of my conversation with Andrew MacLeod. In part four, we discuss how trust and communication between drivers and autonomous cars will evolve.

About the author

Edward Bernardon is vice president of strategic automotive initiatives for the Specialized Engineering Software business segment of Siemens PLM Software, a business unit of the Siemens Industry Automation Division. Bernardon joined the company when Siemens acquired Vistagy, Inc. in December, 2011. During his 17 year tenure with Vistagy, Bernardon assumed the roles of vice president of sales, and later business development for all specialized engineering software products. Prior to Vistagy, Bernardon directed the Automation and Design Technology Group at the Charles Stark Draper Laboratory, formerly the Massachusetts Institute of Technology (MIT) Instrumentation Laboratory, which developed new manufacturing processes, automated equipment and complementary design software tools. Bernardon received an engineering degree in mechanical engineering from Purdue University, and later received an M.S. from the Massachusetts Institute of Technology and an MBA from Butler University. He also holds numerous patents in the area of automated manufacturing systems, robotics and laser technologies.