The model based enterprise’s role in ongoing JT efforts

Industry needs to be able to ask and answer “What’s next?” to discover ideas that will transform the market. Leading companies in industry today are thinking about how to solve what might be called “the next big problem.” The methods that companies use to discover innovative ideas to arrive at a solution for what’s next will make or break how that idea performs in the market.

In this series, we explore how a model based enterprise utilizing 3D JT data can help companies answer questions about what’s next in industry and what’s next for JT. In part 1 of this series, I discussed the impact electricity and the light bulb had on industry. The ability to visualize 3D JT data freely in an enterprise was the “light bulb” moment for model based engineering.

Here, I discuss how model based definitions and enterprises are the next step in the JT effort.

Why a model based enterprise is the next step

A model based enterprise (MBE), and the practices required to support it, provide a pathway for the process of distributing innovation throughout an enterprise. When companies successfully create an MBE using 3D JT data, they have model based definitions capable of addressing issues present in product development, product manufacturing and processes beyond.

Where did the idea for a model based enterprise come from? As computer aided design (CAD) became the norm in industry for design and engineering, the full product development process became based on 3D models. 3D models are now the foundation for virtually all of discrete manufacturing. Using 3D data, the model base enterprise is extended beyond product development to all facets of industry, including end users in marketing, maintenance and purchasing.

Serious problems develop as a broad range of users begin using 3D engineering data sets. Full design content has intellectual property that isn’t meant for general distribution; downstream users need read-only access to 3D models, and product manufacturing information must be able to replace drawings. There are immense risks with how data is managed. Companies must guarantee control of their data sets. With 3D data formats such as JT, which is an international standard for visualization and collaboration, users can trust the data they see and be sure the content is controlled and secure.

Data formats such as JT help companies decrease the time required to develop products and maintain accountability. With a model based definition using 3D JT data, companies can create data that is complete, accurate, controllable and easily accessible.

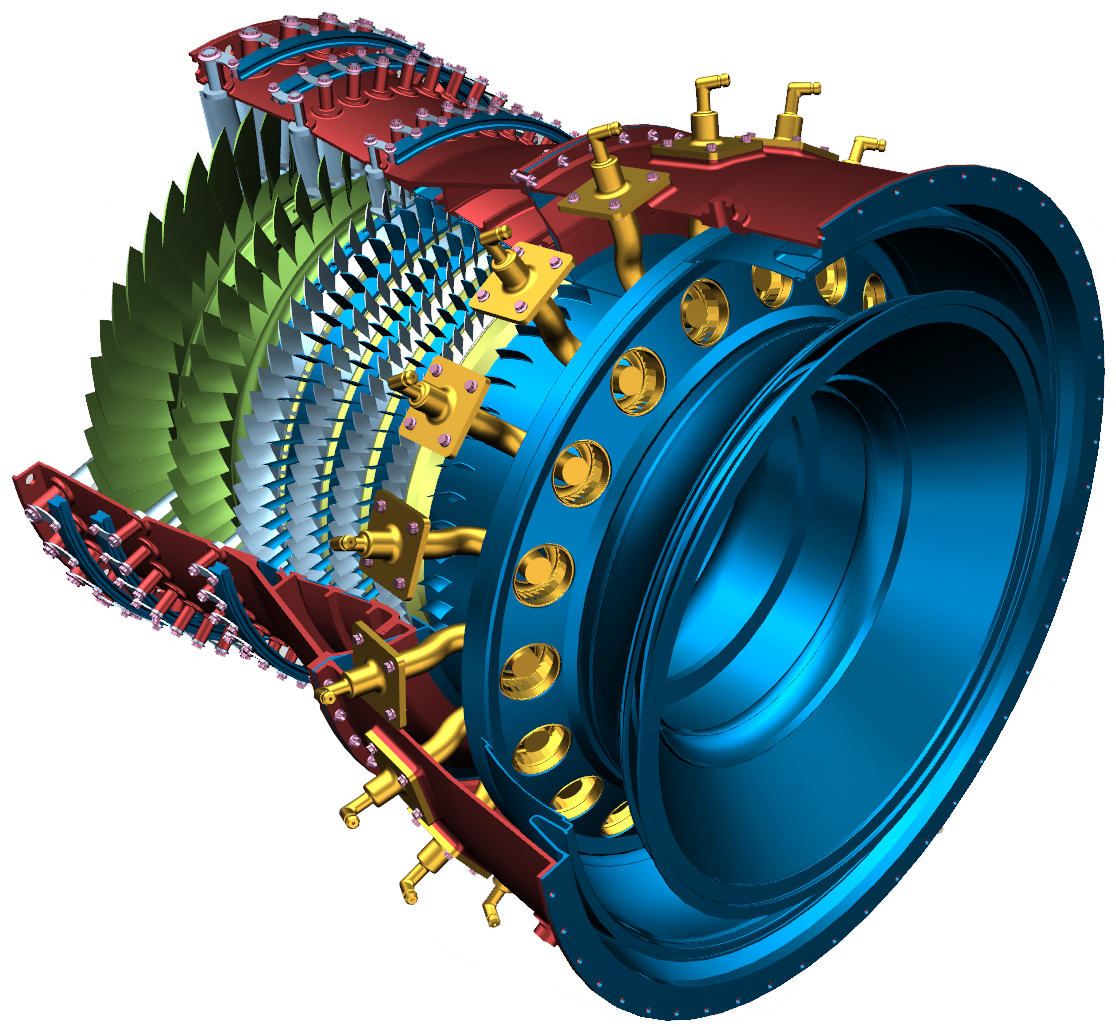

Model based definitions with 3D JT data gives you the ability to create data that is accurate, complete and easy to access.

Model based definitions with 3D JT data gives you the ability to create data that is accurate, complete and easy to access.

The model based definition and digitalization

To have a model based enterprise, there must be a process for model based definition (MBD). Integral to model based definition is digitalization. A core component of digitalization is the digital thread, which connects valuable information about a product and how it performs throughout its entire lifecycle. The digital thread can have increased impact on a company’s performance the longer it is in place. A digital thread can even dictate how a company completes certain processes.

This idea of the digital thread connecting valuable information ties directly into MBE. Like the digital thread, the JT file is everywhere in model based definitions. JT files are the major player in creating a full distribution system for your innovation, which means the JT file can be the catalyst for the next big idea your company wants to bring to the market.

This is where Siemens PLM enters the model based enterprise conversation. Siemens PLM is developing and enabling solutions that give customers the means to deploy successful digitalization solutions. Like MBE, these solutions can transform the entire product lifecycle – which means customers have the tools they need to harness their big idea and bring it to the market.

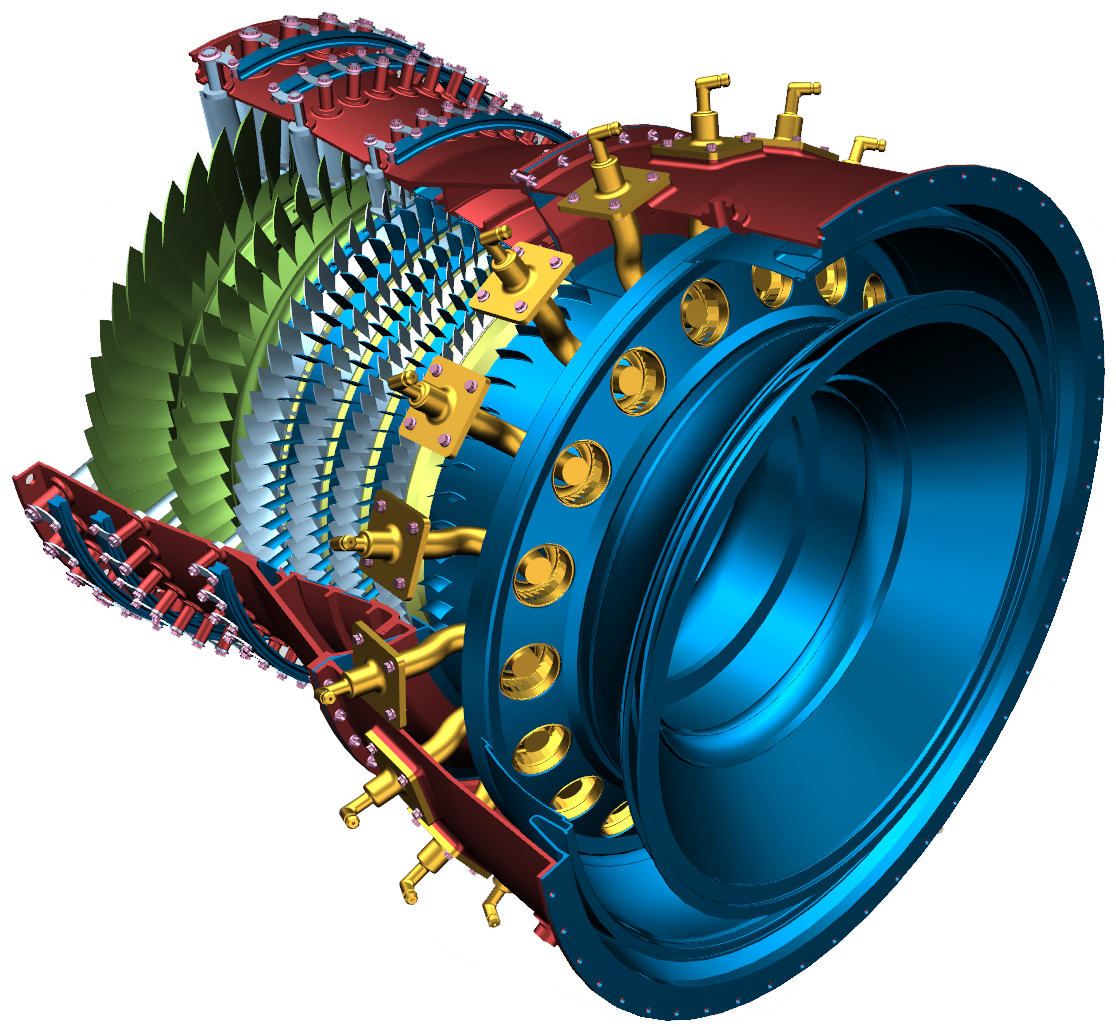

Model based enterprises gives your company the means to bring your next big idea to the market.

Model based enterprises gives your company the means to bring your next big idea to the market.

This concludes part two of our series on MBE. In part three, we examine Siemen PLM’s role in MBE and four things happening today that will be the catalyst for the next big idea.

About the author

Mike Zink is a Senior Product Manager and Openness Evangelist working in the Corporate Technology Office of Siemens PLM Software. He has more than 36 years of experience with software product development, project management and manufacturing support. Mike currently has product management responsibility for the Siemens PLM JT Toolkit, PLM XML Software Development Kit and JT2Go, the 3D data viewing tool for JT. He is also the Siemens PLM Software openness evangelist and encourages openness in industry through programs such as the Code of PLM Openness and ISO standardization of JT. Mike has a Master’s degree in software development and management and a Bachelor of Science degree in computer science from the Rochester Institute of Technology.