On a mission for zero-failure automotive electronics

By Steve Pateras – Mentor, A Siemens Business

Auto makers and tier 1 suppliers need to understand the basics of testing semiconductor ICs after they are manufactured and throughout their operational lives.

Quality, safety, and reliability in automotive electronic systems are more important than ever. Those systems, of course, are only as good as the silicon integrated circuits (ICs) that drive them. Testing the ICs that make up automotive electronic systems is a critical step in the race to fully autonomous vehicles. OEMs and suppliers need to understand what’s involved in making an automotive-grade IC, including how the circuits are tested after being manufactured and during the lifetime operation of the IC in the system. Consider this blog to be a brief tutorial on semiconductor IC test.

Quality, safety, and reliability in automotive electronic systems are more important than ever. Those systems, of course, are only as good as the silicon integrated circuits (ICs) that drive them. Testing the ICs that make up automotive electronic systems is a critical step in the race to fully autonomous vehicles. OEMs and suppliers need to understand what’s involved in making an automotive-grade IC, including how the circuits are tested after being manufactured and during the lifetime operation of the IC in the system. Consider this blog to be a brief tutorial on semiconductor IC test.

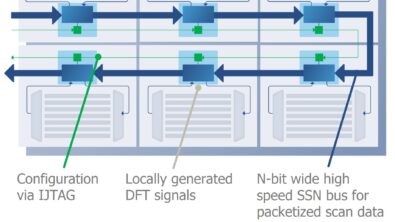

Semiconductor designers add dedicated circuitry to the IC designs that deliver test stimuli to circuitry and collect the responses to the stimuli. After the IC is manufactured, it is connected physically to a specialized tester via a probe or cable to the external test ports or pins that then send stimuli through the dedicated test circuitry. The responses to those stimuli indicate potential chip defects that could lead to failures. For automotive applications, the goal is zero defects. However, the specialized test equipment is expensive, so semiconductor makers are always working on ways to test thoroughly but more efficiently.

After manufacture and testing, ICs end up in ECUs made by tier 1 suppliers and are tested again in that system. Those ECUs end up in automobiles and are tested again before the vehicle is sold. However, all the electronic systems need to be tested throughout their lifetime of operation in the vehicle. This self-test is done without an external tester. Every time you turn on the ignition, the car systems go through a power-on self-test, right down to checking the ICs in the systems. This is done through a technology called built-in-self-test (BIST). BIST is fast and does not require external testers, which has led to it also being used along with traditional test at the manufacturing stage to control test cost.

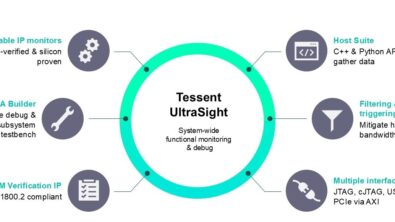

All the new pressures and requirements for safety-critical automotive ICs requires some adjustments to traditional IC test strategies. Mentor, a Siemens business, has been a leader in semiconductor test for many years and now offers new test software that allows the makers of automotive ICs to develop the most reliable products for the era of fully-autonomous driving.

Our latest innovation for in-system testing for automotive ICs is called Tessent MissionMode. It is both software and hardware (in the form of a finite state machine that is added to the IC). Tessent MissionMode is notable for two reasons:

- It is the first commercial automated solution that enables ICs in the vehicle’s electronic systems to easily communicate errors to the main controller, which can warn drivers, send data to service centers, or execute self-repair.

- It allows, for the first time, continuous testing in the system ICs during operation, not just test at power-on.

How does BIST work? An on-chip controller sends messages (test patterns) to its assigned circuitry and uses the response to determine that it is functioning properly. Basically, the BIST controller says, “Hey, you okay?” and the functional circuitry says, “Affirmative!” If a response is returned with a variation, the BIST controller will flag it and send it to the MissionMode controller. BIST blocks typically provide simple pass/fail results but can be configured to provide more detailed diagnostic information. For example, a BIST controller can say not just that a particular memory chip failed, but specify the address and bit location of a failure. This information can be used to repair the memory on the fly by swapping in a spare memory element.

The MissionMode controller can also take direction from the main ECU to take corrective, self-repair action or obtain additional diagnostic information. The system could also be configured to record the source and type of error that occurred and even where it occurred on the chip. This data can help service centers find the exact parts that need replacing, help auto makers identify problem parts and adjust inventories, and could help the semiconductor companies or foundries remedy the problem in subsequent runs of the chip and future designs.

The Tessent MissionMode technology builds on other test capabilities to ensure the highest safety and reliability in ISO 26262 compliant ICs designed for use in automotive electronics. Mentor’s Tessent family of silicon test and yield analysis tools are SGS-TUV Saar certified as standalone tools or in a tool-chain up to and including ASIL D for any tool confidence level (TCL).

To learn more, download this new whitepaper Tessent MissonMode: New Runtime DFT Technology Paves Way for Self-Correcting Automotive Electronics