Supercharge battery module manufacturing with Process Simulate software [WEBINAR]

The battery industry expects more than 30 percent annual growth in the next decade to reach $100 billion in revenue by 2026, driven primarily by electric vehicle development. In an upcoming webinar hosted by Siemens, explore common battery cell manufacturing challenges and how virtual commissioning software like Siemens Tecnomatix Process Simulate drives smart manufacturing solutions to address these complexities.

The battery manufacturing industry

In this upcoming webinar, explore critical hurdles in automotive battery production, and how Siemens Tecnomatix Process Simulate enables battery OEMs and line builders to improve safety, reduce costs and accelerate time to market. By simulating production processes in a virtual environment, manufacturers can identify and mitigate potential issues before they arise on the factory floor.

From planning to mechanical, robotics, electrical, and automation, the traditional sequential design and engineering processes often fail to meet the fast-paced demands of the modern battery manufacturing landscape. These siloed approaches can result in misalignments and inefficiencies that are only discovered during the physical commissioning phase, leading to delays and increased costs. Moreover, they do not provide sufficient foresight into potential performance issues or maintenance needs once the production line is operational.

Join us to learn how virtual commissioning can help propel your battery manufacturing processes forward.

Application Engineer

Siemens Digital Industries Software

Solution Domain Expert

Siemens Digital Industries Software

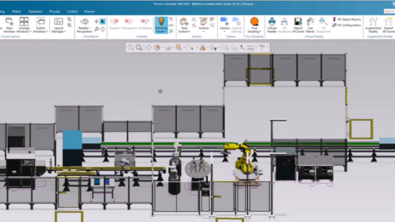

To address these challenges, Process Simulate offers an integrated solution through virtual commissioning. This tool enables a cohesive approach across various engineering disciplines, ensuring that all components and systems are aligned from the outset. In an upcoming webinar, explore a new battery module assembly line that illustrates the benefits of Process Simulate. The line includes several critical stages, from robotic handling and assembly to quality inspection, each designed to streamline the manufacturing process.

Challenges and solutions

Whether you are a battery OEM, line builder, or a manufacturing professional looking to stay ahead in the industry, this webinar will help inform battery makers how to embrace smart manufacturing, digital manufacturing software, and digital twin technology to help improve the end-to-end process.

Process Simulate addresses several challenges in robotics and equipment management by enabling virtual planning, testing, and validation. It optimizes robot path planning to prevent collisions and ensure efficient space use, facilitates the rapid development of production-ready robot programs with minimal on-site debugging, and detects potential interference to ensure safe robot operation. Additionally, it supports equipment validation by reducing risks through virtual testing and accelerates the commissioning process by simulating the entire production workflow, ensuring reliability and efficiency before physical deployment.

Battery manufacturers benefit from improved workflow, accelerated product launches, and enhanced product quality by streamlining processes and resolving issues early. Line builders and system integrators gain efficiency, meet project deadlines, and enhance market competitiveness by reducing on-site work and avoiding hardware design errors.

As the EV market expands, the need for efficient and scalable battery manufacturing will intensify. Process Simulate provides a critical edge by enabling virtual commissioning, optimizing production, and positioning manufacturers and line builders for future success in a competitive industry.

Interested in learning more? Join Siemens experts in an upcoming webinar and register now to learn more about Process Simulate can help support smart manufacturing initiatives.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)