Electronics Assembly Reinvented: Simulate, Optimize, and Commission for Smarter Production

Discover how next-generation simulation and flexible automation are reshaping modern electronics assembly. By validating robotic workflows before they hit the production floor, manufacturers can reduce deployment risks, streamline changeovers, and accelerate time-to-market – all while improving product quality and lowering operational costs.

The electronics assembly industry is entering a period of significant growth and transformation. With global demand for smarter, smaller, and more reliable devices accelerating, manufacturers are expanding production capacity, investing in automation, and rethinking traditional workflows. From consumer electronics to aerospace systems, the need for high-quality, high-precision assembly has never been greater – making the industry outlook not only promising, but strategically important for the broader technology ecosystem.

This growth is being shaped by several key trends, including miniaturization, greater automation, and the drive for faster time-to-market. Manufacturers are increasingly adopting robots, intelligent vision systems, and flexible production setups to improve precision, handle rapid changeovers, and maintain consistent quality. At the same time, there is a stronger emphasis on process efficiency and reliability, as even small defects can have a significant impact on production outcomes. These shifts are redefining traditional assembly workflows and driving the industry toward smarter, more resilient manufacturing practices.

Despite rapid adoption, robotics in electronics assembly still face practical integration challenges. Traditional methods – installing and adjusting equipment directly on the shop floor – no longer work well when product cycles are short, layouts are tight, and downtime is costly. Planning a robotic cell now means carefully considering space, workflow, tooling, and motion paths, while avoiding interference with existing equipment or operators. Programming and tool validation add further complexity as product variants grow. Simulation and virtual commissioning are essential because they let teams explore layouts, test robot paths, and validate tooling before physical setup. These technologies help reduce uncertainty, speed up deployment, and support more flexible, efficient automation.

Integrate, validate and enhance robotic assembly

To begin, let’s explore how Process Simulate can help tackle today’s electronics assembly challenges, allowing manufacturers to plan, test, and optimize robotic assembly processes before applying them on the production floor.

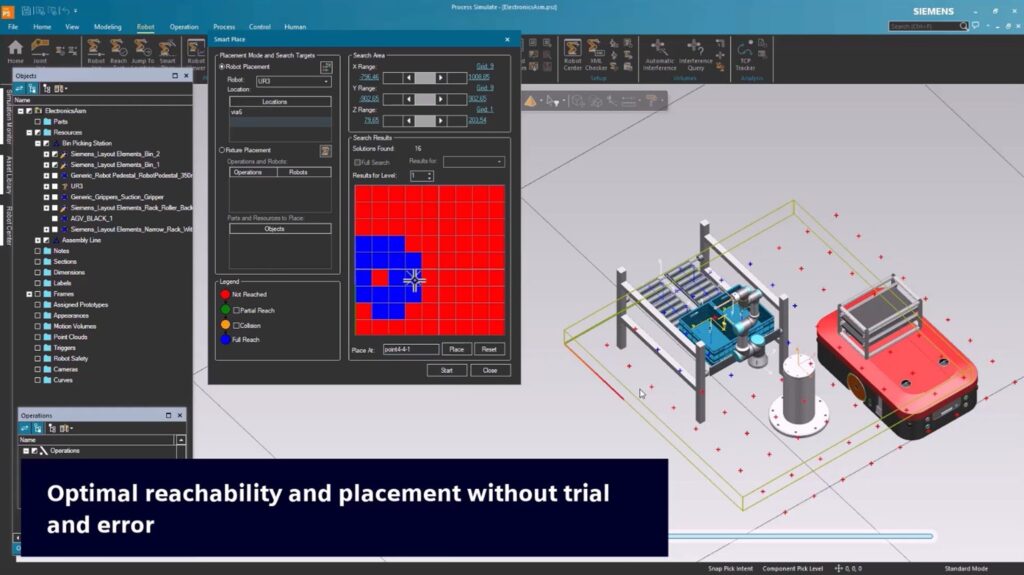

Layout Planning

Layout planning in electronics assembly is a complex task, but Process Simulate streamlines the process and boosts efficiency. Engineers can leverage its comprehensive cloud-based asset library of machines, conveyors, and robots, along with quick layout tools, to rapidly build production cells and explore multiple configurations. The platform allows teams to test and select optimal robot positions, optimizing space utilization, improving workflow, and identifying potential mechanical interferences early. By validating arrangements virtually before any physical installation, teams ensure safe and efficient equipment placement, minimize costly rework, and significantly reduce the time and effort required to plan even the most intricate assembly lines.

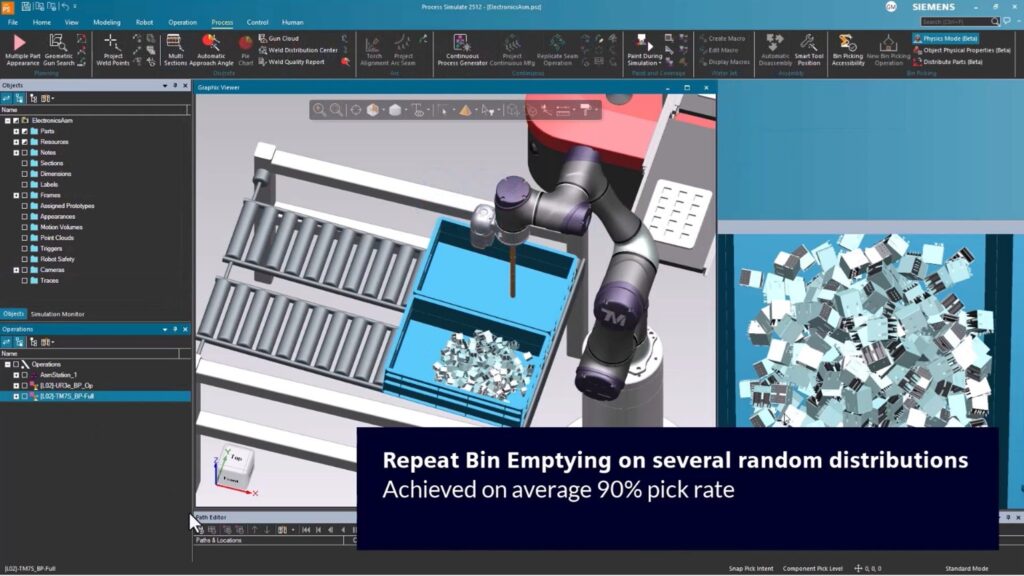

Tool Validation and Bin-Picking

With the layout in place, the next step is ensuring robots can handle parts reliably and efficiently. In electronics assembly, bin picking and tool validation remain key challenges for reliable automation. Robots must pick parts from bins with varying orientations and densities, and grippers need to perform consistently across different components. Process Simulate provides dedicated bin picking features that, combined with physics, allow engineers to test feasibility in terms of accessibility and collision, ensuring that the robot can reach every part without interfering with surrounding equipment. By virtually validating grippers, tooling, and pick strategies with physics-enabled accuracy, teams can reduce mispicks, optimize handling, and accelerate the deployment of new tools or part variants, ultimately improving production efficiency and reliability.

For example, think of a manufacturer assembling smartphone circuit boards that needs a robot to pick small metal brackets from a bin. Because the brackets land at random angles, the robot sometimes can’t reach them, collides with the bin wall, or drops parts due to poor grip.

Using Process Simulate, engineers test the entire process virtually:

- Run physics-based bin-picking scenarios with different part orientations

- Identify unreachable areas and potential collisions

- Compare gripper designs (two-finger, vacuum, hybrid) for consistency

- Refine pick strategies and bin angles for higher success rate

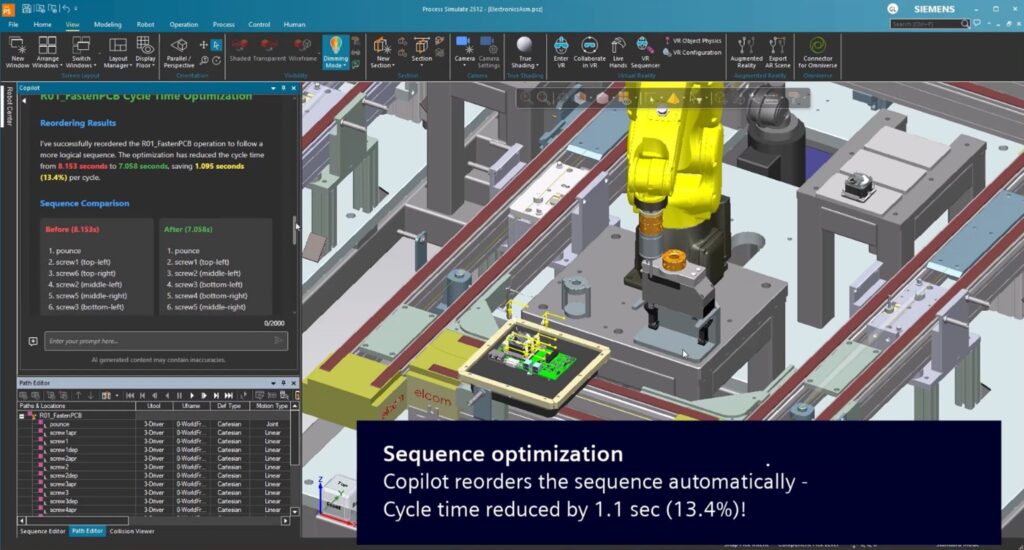

Robot Motion Planning

After addressing bin picking and tool validation, the focus shifts to optimizing robot motion for the rest of the assembly cell. In classic, non-random processes – such as soldering, fastening, or component placement – robots must follow efficient, collision-free paths while coordinating multiple axes and tools. Process Simulate provides a virtual environment where engineers can plan, test, and fine-tune these movements before any physical deployment. The AI Copilot feature takes this a step further by automatically suggesting optimized trajectories, identifying potential collisions, and recommending adjustments to improve cycle times and workflow efficiency. By leveraging these capabilities, teams can reduce trial-and-error on the shop floor, ensure safer and more efficient operations, and accelerate the deployment of high-performing robotic systems across the assembly line.

Robot Programming

Once robot motions are optimized, the next step is turning those paths into precise, executable programs for the robots on the shop floor. Programming can be complex, especially when dealing with multiple tools, part variants, intricate sequences, or integrated logic instructions. Process Simulate streamlines the process by allowing engineers to generate, test, and fine-tune robot programs entirely in a virtual environment. Programs can be validated against the full assembly cell to check for collisions, tool coordination, cycle times, and logic execution. Once finalized, the programs can be downloaded directly to robots, regardless of vendor, ensuring accurate execution and reducing risk. This approach accelerates programming, boosts reliability, and gives teams the confidence to implement robotic operations effectively.

For example, think of a manufacturer building tablet motherboards uses a robot that must switch between a vacuum picker, a screwdriver, and a vision sensor during assembly. Programming all these tool changes and motion sequences on the shop floor would normally take days — and mistakes could cause collisions or downtime.

With Process Simulate, engineers create and test the entire robot program virtually:

- Define tool-change sequences and logic

- Validate motions against the full cell to avoid collisions

- Check cycle time, reachability, and coordinated movements

- Test different part variants without disrupting production

Mechanical Interference

Besides robots, non-robotic devices such as THT (Through-Hole Technology) machines and surface-mount machines play a crucial role in electronics assembly. These machines have fixed motions and defined reach zones, which can create challenges in terms of mechanical interference and accessibility. Ensuring they can operate without colliding with nearby equipment or restricting the movement of other machines is essential for smooth production. Process Simulate helps engineers address these challenges by modeling the devices virtually, testing reachability, motion range, and potential collisions within the full assembly cell. By resolving interference issues early, teams can optimize machine placement, maintain efficient workflows, and reduce costly adjustments during physical setup.

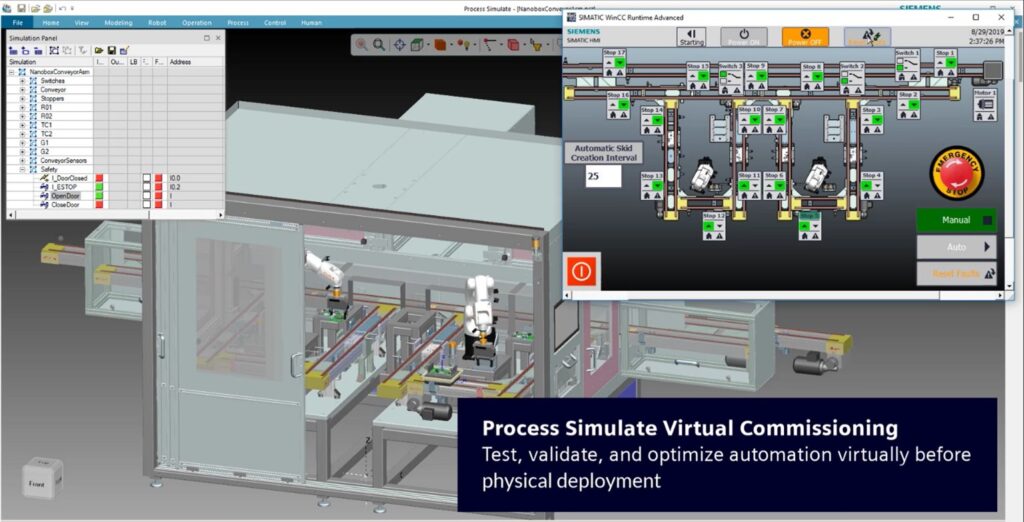

Virtual Commissioning

Once the equipment has been optimized and validated virtually, the next step is bringing the entire assembly line together through Virtual Commissioning. This process allows engineers to test the full system – including robots, THT machines, surface-mount machines, conveyors, and other devices – in a simulated production environment before any physical setup. Process Simulate enables teams to identify potential bottlenecks, collisions, or control issues, ensuring that every component works together seamlessly. By simulating the interactions of the full assembly cell, engineers can optimize workflows, validate control logic, and reduce the risk of costly downtime during installation. Virtual Commissioning with Process Simulate accelerates deployment, improves reliability, and gives manufacturers confidence that their electronics assembly line will operate efficiently from day one.

Think of a global electronics manufacturer producing smartwatches and is setting up a new automated cell to handle final assembly. The line includes robots for battery placement, adhesive dispensing, and display installation, along with curing stations, precision conveyors, and end-of-line functional testers. These operations require tight coordination and high precision due to the small size and delicate nature of the components.

Before building the physical cell, the engineering team uses Virtual Commissioning in Process Simulate to validate how everything works together:

- Link robot programs, dispenser logic, and improving cycle timings

- Confirm that display-handling robots don’t interfere with adhesive tooling

- Test conveyor indexing to ensure each watch case reaches stations at the right time

- Validate safety zones, interlocks, and sensor behavior under different product variants

- Simulate full production flow, including bottlenecks during battery placement and fixing delays

In electronics manufacturing, where tight tolerances, rapid product refreshes, and high-volume output leave little room for error, getting a production line right the first time is critical. Process Simulate gives electronics manufacturers the ability to virtually validate every pick, place, solder, and inspection step long before hardware is installed. Instead of uncovering issues during commissioning—when rework is costly and delays ripple through the entire launch—teams can identify problems early, optimize cycle times, and ensure each station works seamlessly with the next. By combining manufacturing simulation with virtual commissioning, electronics manufacturers reduce ramp-up time, minimize downtime, and consistently deliver the reliable, high-quality assemblies today’s devices demand. It’s a smarter, more predictable way to bring new PCB lines, final assembly cells, and high-precision processes online with confidence. Stay tuned as we continue to explore this topic in an upcoming webinar.

Interested in launching the trial? Try Process Simulate free for 30 days

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)