Discover what’s new in Tecnomatix 2408 (August 2024)

Digitalization for advanced manufacturing.

The Tecnomatix® portfolio delivers advanced digital manufacturing software to empower businesses across diverse industries and sizes. Tecnomatix 2408 launched recently with several exciting new advancements in the areas of cloud computing, Teamcenter connectivity, UI updates, collaboration, augmented reality, robotics simulation, offline programming, virtual commissioning, human simulation and virtual reality.

In this blog, we explore how the Siemens Xcelerator portfolio, including Tecnomatix digital manufacturing software, helps companies minimize manufacturing risks and improve their production operations. Siemens Xcelerator is an open digital business platform that enables customers to accelerate their digital transformation easier, faster and at scale.

Tecnomatix software helps companies minimize manufacturing risks and improve their production operations. We are excited to bring these latest enhancements to you!

You don’t have Tecnomatix software?

General enhancements

See the highlights from Tecnomatix 2408:

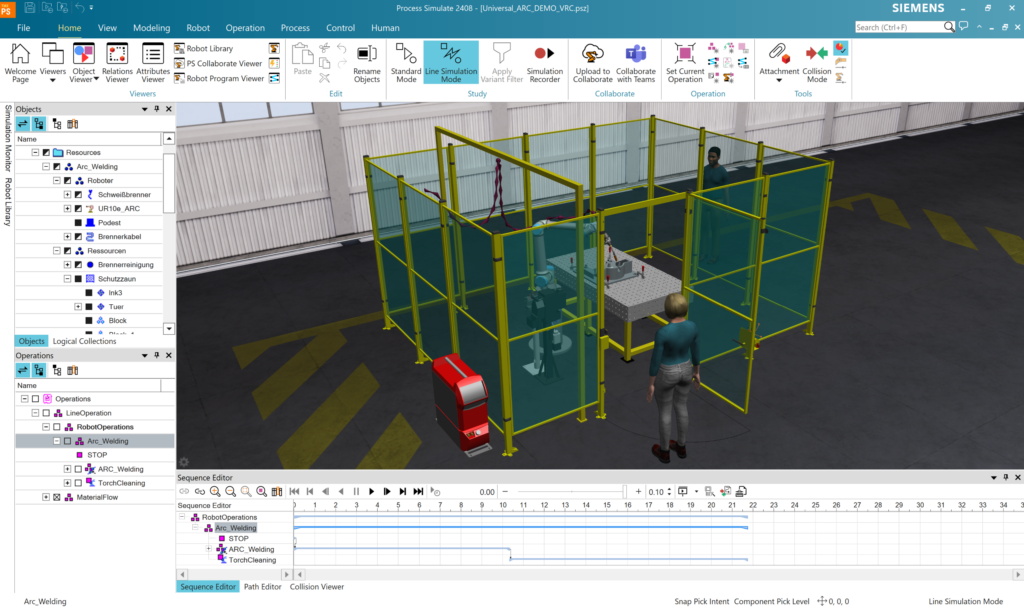

Process Simulate X

We are thrilled to unveil Process Simulate X, cloud-enabled digital manufacturing software for planning, simulating, and validating human tasks, robotics processes, and automation in a 3D environment. In 2408, you can expect the benefits of cloud-based deployment, enabling manufacturers to gain the flexibility and security they need to scale their operations efficiently.

This advanced software is tailored to manage any manufacturing complexity, allowing manufacturers to quickly validate concepts and adapt their systems throughout the product lifecycle from concept, engineering and commissioning to production and continuous improvement. Cloud-based deployment ensures streamlined software installation and configuration, which translates to higher productivity and rapid expansion of digital manufacturing capabilities. Paired with Process Simulate X add-ons, companies can customize their software access to meet their specific needs. Stay tuned to learn more about the new product offerings and suite of add-ons that elevate your digital manufacturing.

Process Simulate on Teamcenter

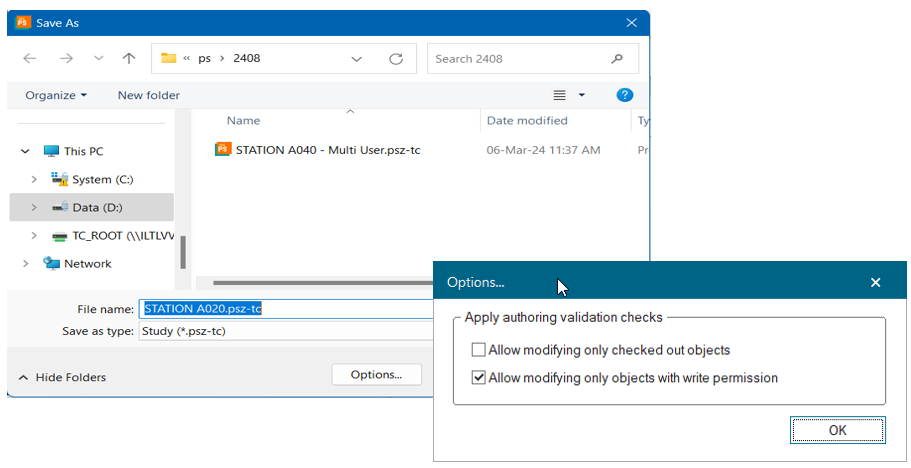

Authoring enhancements

Explore new integration enhancements for Process Simulate on Teamcenter, starting with authoring improvements. To further ease authoring in Process Simulate on Teamcenter, Tecnomatix 2408 introduces Tecnomatix Doctor options that are not exclusively applicable to Process Simulate within Teamcenter when managed studies are loaded, with a default setting that validates write access. For standalone studies, you can configure specific authoring setting for each study through a newly added Options dialog. This enhancement enables flexible management of standalone files, allowing for distinct settings that facilitate later integration back to the servers, or less stringent configurations for studies intended for intermediate checks that won’t be integrated into Teamcenter.

VC Lite CAD import application

The Process Simulate VC Lite CAD Update enhances data integration through its “convert and insert CAD files” command, which now supports importing newer versions of all major CAD data formats. This update allows you to seamlessly convert and import files into version 10.6 JT format, matching the quality of those generated by the “Export JT” command. With improvements in file format support, bug fixes, and optimized performance, this update provides a more efficient and reliable workflow, facilitating easy data flow and enhancing productivity in the simulation process.

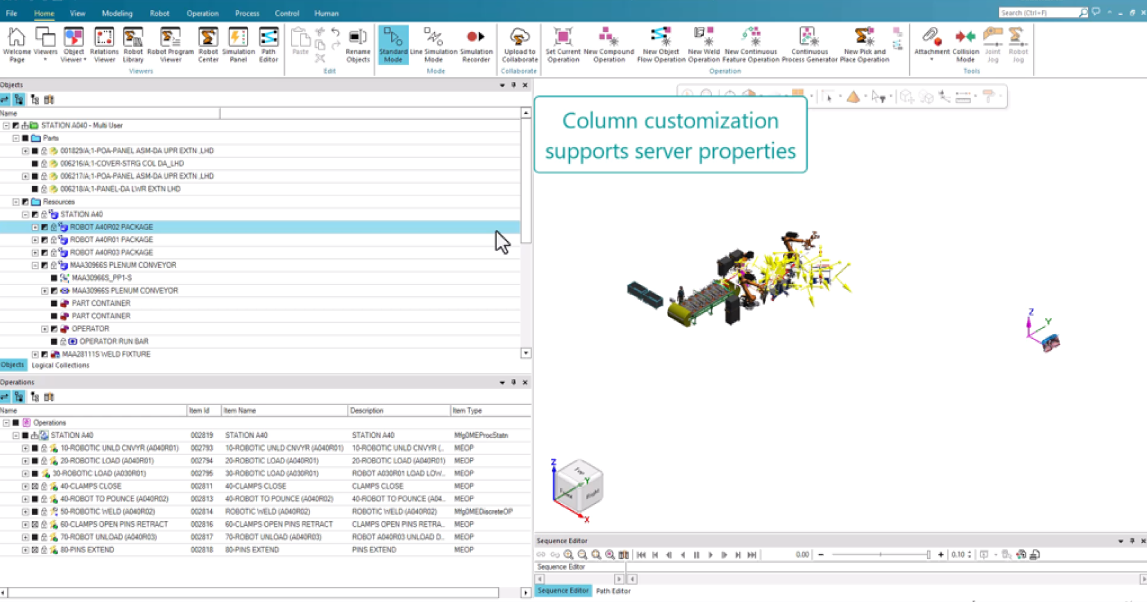

Customizable viewer columns

The enhanced viewers now feature customizable columns that display server attributes defined through personalization, making crucial object information readily accessible without the need for extensive searching. Supporting both eMServer and Teamcenter attributes, you can filter, zoom, and customize columns across various viewers, including objects, operations, logical collections, robot center, signals, and selected objects. Easily sort viewer content by any column, with intuitive controls that allow for quick adjustments and multiple-column sorting. The filtering capability enhances your experience by enabling precise content management based on column values, with visual indicators for applied filters. This streamlined access to information significantly improves efficiency and productivity in navigating complex data.

Process Simulate Collaborate

Tecnomatix Process Simulate Collaborate is a cloud-based, 3D collaboration solution to visualize, review and analyze Process Simulate studies in a collaborative environment. The 3D simulation collaboration tool helps save time and effort by extending Process Simulate studies into the cloud, providing internal and external stakeholders access to the richness of your Process Simulate studies, saving time and effort. Collaboration is much improved via dynamic 3D visualization, simulation and electronic feedback.

The Tecnomatix 2408 release introduces several innovative capabilities in Process Simulate Collaborate that enhance collaboration and efficiency in engineering workflows. Key features include:

Point cloud integration

You now can upload point cloud (.pod) data for visual inspection and layout planning, enabling precise measurements relative to surrounding 3D objects.

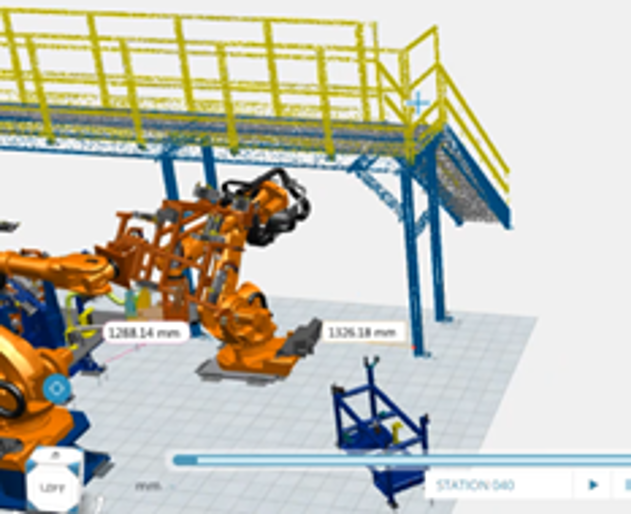

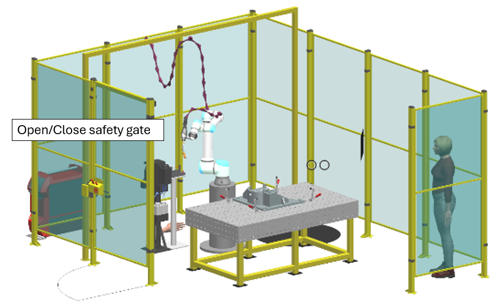

Safety review

This new capability helps engineers streamline workflows for safety planning and validation, specifically for automation and robotics stations, ensuring a safer working environment.

Virtual reality (VR) collaboration

The immersive VR collaboration tool allows teams to conduct engineering reviews within a virtual environment, enabling colleagues to participate remotely in Process Simulate studies.

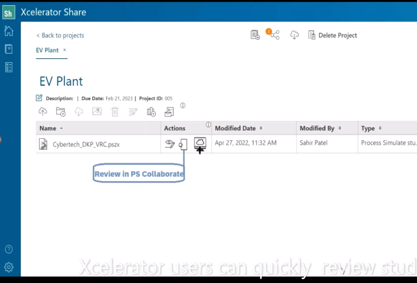

Teamcenter Share Integration

You can directly open studies from Teamcenter Share in Process Simulate Collaborate for efficient review, fostering better communication and teamwork.

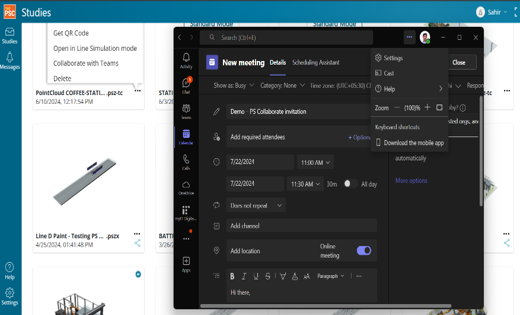

Microsoft Teams Integration

Process Simulate Collaborate users can quickly set up Microsoft Teams meetings with an embedded session link in the invite, facilitating seamless collaboration and communication.

Robotics

Process Simulate Robotics helps you to program and validate your robotic processes in a dynamic 3D environment. It includes robotics applications for spot welding, metal processing, drilling and riveting, surface treatment and assembly.

The following new capabilities were released in Tecnomatix 2408.

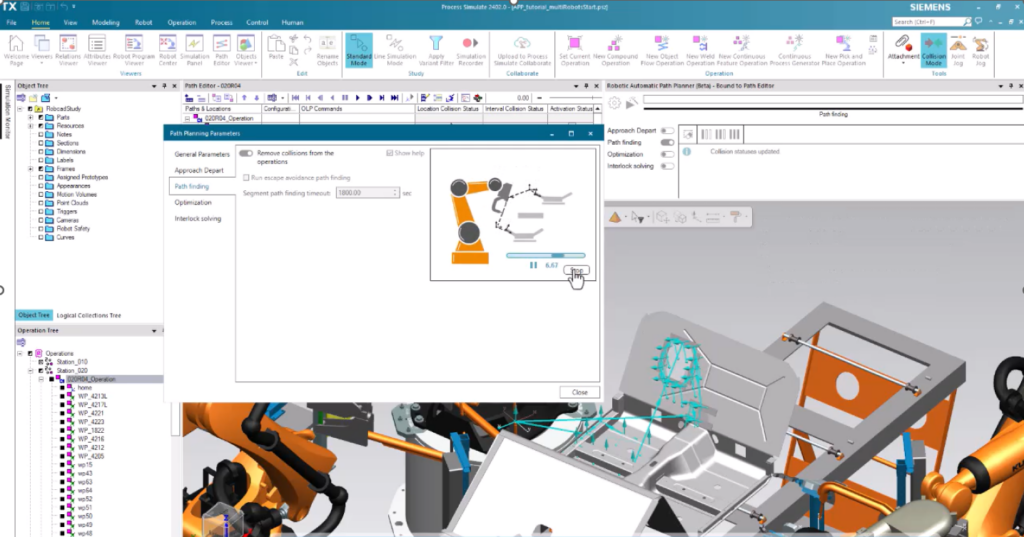

Robotic automatic path planner

The Robotic Automatic Path Planner significantly enhances robotic path planning capabilities in 2408. This upgraded capability offers a more intuitive user experience, making it easier for new users to ramp up. Key features include advanced interlock solving for operations within the same sequence, integrated collision analysis, and a comprehensive path editor. Additionally, it provides detailed monitoring, animated explanations of algorithms, and improved collision status calculations for locations and intervals. These enhancements support a wide range of robotic operations, including welding and pick-and-place tasks, making the Robotic Automatic Path Planner an essential tool for optimizing robotic performance.

The Robotic Automatic Path Planner introduces advanced features that enhance collision detection and user interaction, significantly improving robotic operations. It now supports smart gun-tip collision detection, allowing you to secure collisions without impacting simulation performance. Additionally, the planner automatically manages self-collisions, providing a seamless experience by overriding default settings in Process Simulate. The integration of customizable, weld-specified axes further enhances versatility, enabling users to define non-standard vertical and approach axes. Finally, the new “revert all changes since last run” feature offers you the flexibility to undo adjustments easily, ensuring a smoother workflow and reducing errors during simulations.

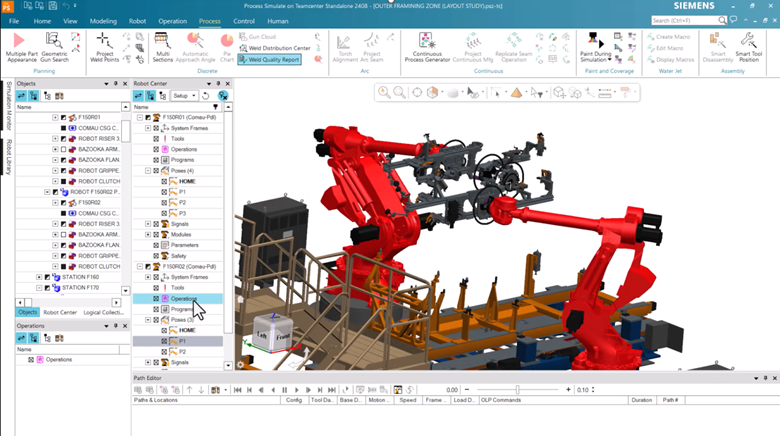

Robot Center

The Robot Center in 2408 streamlines access to all robotic features by consolidating tools into an organized viewer. This new interface allows you to easily navigate through various robotic commands associated with each robot in their study, and significantly reduces the learning curve for new users. The Robot Center supports all controllers, providing tailored setup options, while offering features like filtering by station or robot. These enhancements further unify the interface, allowing for efficient interaction with robot properties and settings in one convenient location.

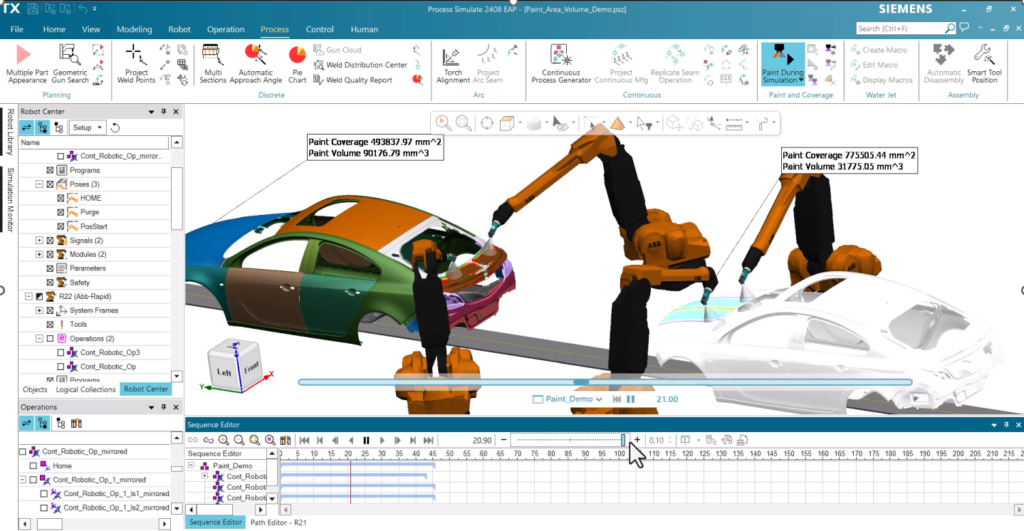

Paint coverage simulation

The paint coverage simulation enhancements enable accurate assessment of moving parts, including scenarios where parts are mounted on turning tables or where the paint gun remains stationary while the part moves. You receive real-time notes during the simulation, detailing the covered area and total paint volume for each part, with this data updating dynamically. At the end of the simulation, you can easily export this information for further analysis. These improvements expand the digital twin capabilities, facilitating better evaluation of paint processes and outcomes.

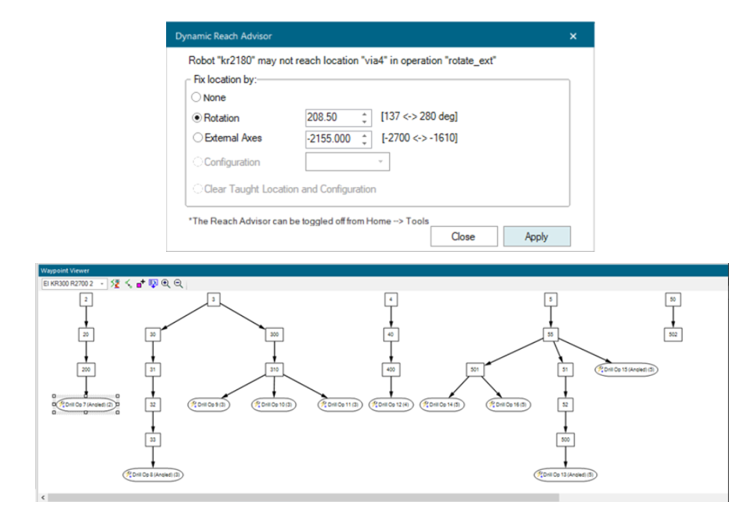

Reach advisor

The reach advisor enhances simulation efficiency by checking the reachability of targets and suggesting corrective actions when necessary, allowing you to select and apply changes seamlessly. This feature is now easily accessible within Process Simulate, improving visibility and user experience. Additionally, the waypoint viewer has been updated to download only connected branches when selecting specific operations or waypoints, streamlining workflow for robots mounted on AGVs. The ability to export programs from the Robot Program Viewer (RPV) to MS-Excel further facilitates collaboration, providing a common reference for engineers and shop floor personnel. Overall, these enhancements offer improved functionality, ease of use, and enhanced collaboration.

The reach advisor improves simulation efficiency by checking target reachability and suggesting seamless corrective actions.

Robot library

In Tecnomatix 2402, the introduction of the robot library viewer ushered in a new era of excitement and efficiency for you with a cloud-based robot library. In 2408, there were significant updates and improvements made, like drag-and-drop functionality for direct insertion of robots into studies across all platforms, including Process Simulate on Teamcenter. you now can easily select the system root path for robot placement and request new models. The library has expanded to include additional brands and models, offering improved usability and quick access to any robot model, enhancing efficiency in robotic simulation workflows.

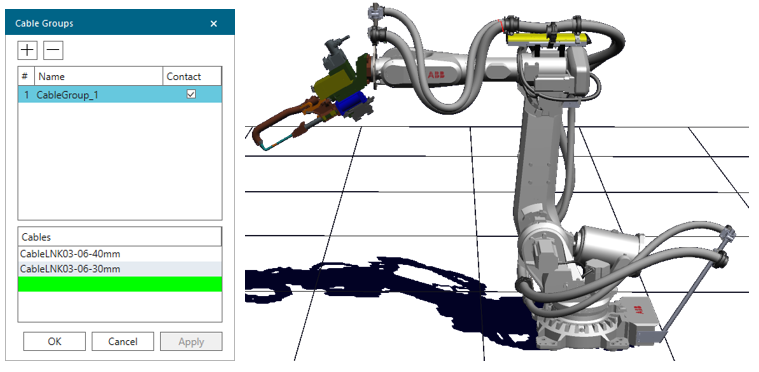

Cable application

The cable group command in version 2408 enhances cable-to-cable contact simulation by allowing you to group cables for more accurate physical behavior during offline programming. Cables within a group actively avoid occupying the same space and colliding with each other, improving collision analysis and 3D motion volume generation for robot dress packages. While a cable can only belong to one group, each group can contain multiple cables, providing flexibility in complex simulations. This feature ensures more realistic and precise dress package simulation during robotic programming.

The cable application also supports the use of pass near frames for cables with attachments, addressing limitations in previous versions. Previously, pass near frames were not considered during cable solving for cables with attachments, but this update allows them to be factored in, enabling more accurate simulations. You now can define a pass near frame for each cable segment through various attachment dialogs, offering greater control over the cable’s initial shape and more precise simulation of its installation location. This enhancement simplifies cable modeling and improves the accuracy of complex dress package simulations during offline programming.

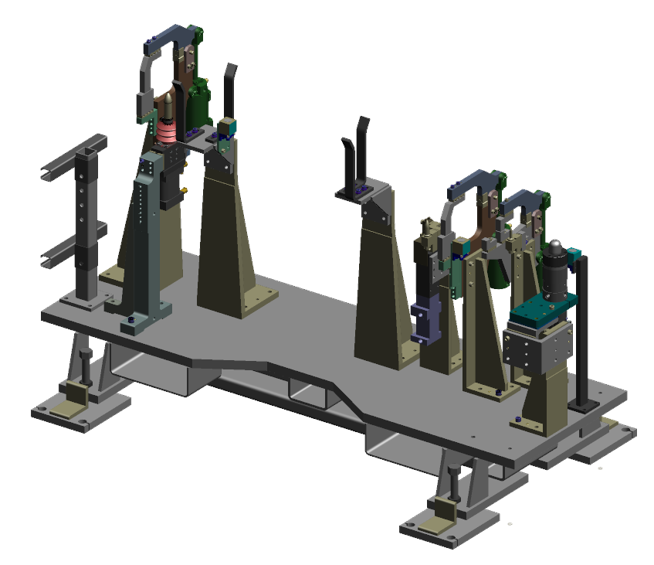

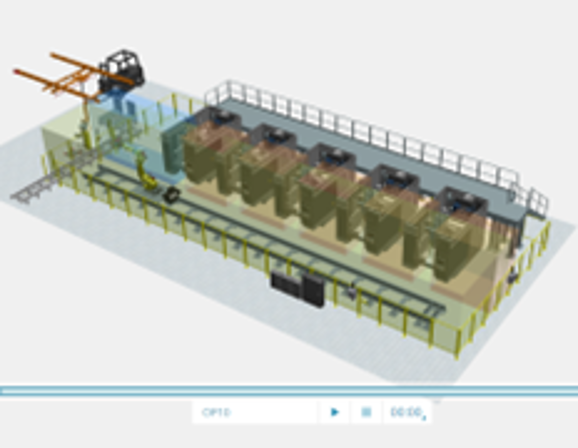

Virtual commissioning

Process Simulate Commissioning helps you to run the PLC code that controls the station to validate robot motion, robot logic and other mechatronic components such as clamps, conveyors and the entire process sequence. Virtual commissioning works with real PLCs (hardware in the loop, HiL) or virtual PLCs (software in the loop, SiL) and with the Process Simulate cyclic event evaluator/emulation (CEE) internal evaluation tool.

The following capability was released in Tecnomatix 2408.

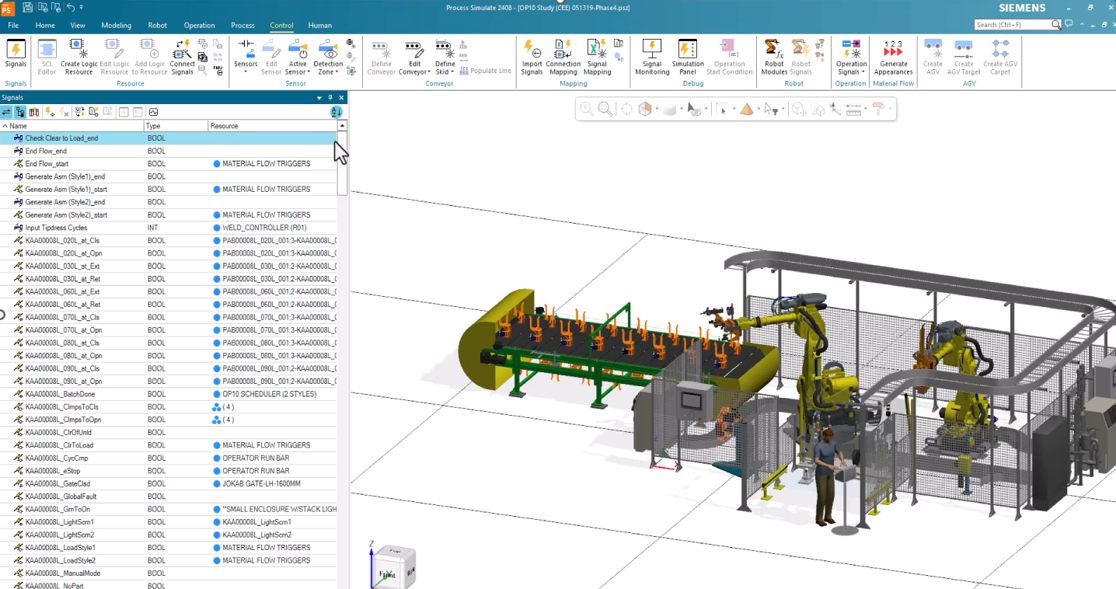

Signal viewer

Process Simulate 2408 includes a new version of the signal viewer, which offers a more advanced and efficient way of managing signals, replacing the previous signal viewer, simulation panel, and robot signals dialogs. Built on the object viewer infrastructure, it provides powerful features such as customizable columns and advanced filtering and sorting capabilities. You can load and monitor all or selected signals with enhanced performance, zoom functionality, and direct interaction with signal values.

Signal viewer offers a more advanced, efficient way to manage signals, replacing the previous signal viewer, simulation panel, and robot signals dialogs.

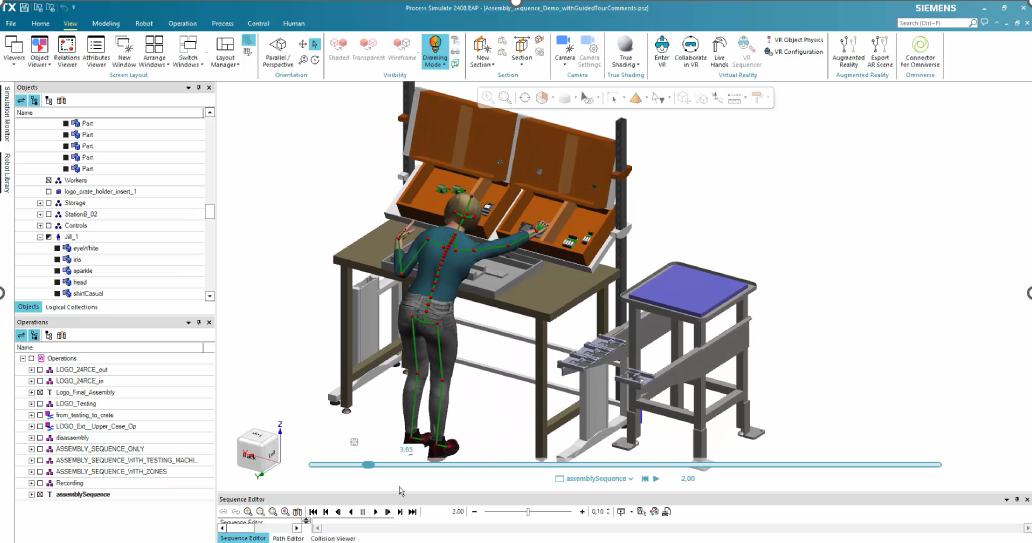

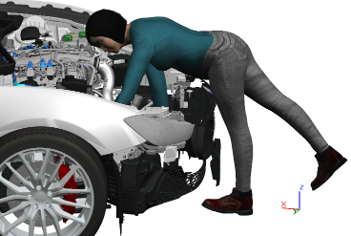

Human simulation and virtual reality

Process Simulate Human helps you to eliminate any risk to operators with walk path analysis, reachability tests, vision analysis, and ergonomics assessments.

Process Simulate Virtual Reality delivers an immersive virtual reality environment for better engineering reviews, staff training and realistic process validation.

The following new capabilities were released in Tecnomatix 2408.

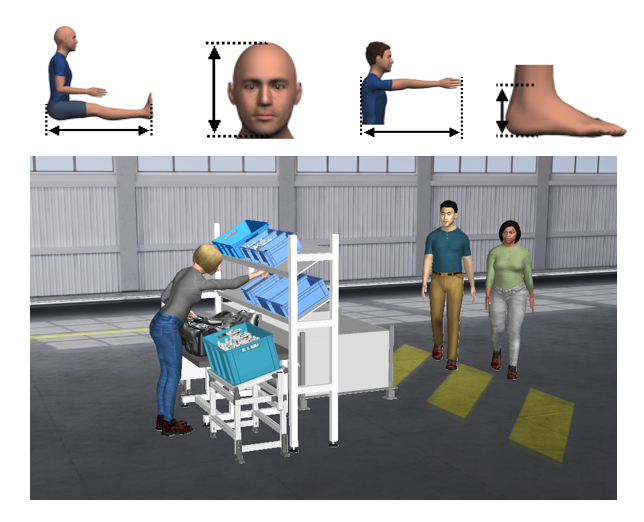

Anthropometric scaling

The anthropometric scaling enhancements offer greater control over human figure size and shape by introducing additional parameters. You can define functional leg length, head height, fingertip reach, grip reach, and ankle height, allowing for more accurate human fit and clearance studies. This update supports the creation of custom figures and ensures compliance with anthropometric standards, making it easier to model realistic human interactions in various environments.

Biomechanics indicators

The biomechanics indicators in Process Simulate Human allow you to inspect the internal framework of the human model, providing detailed visualization of joint locations and body segments. The balance feature enables you to assess whether a human is balanced during task performance, offering valuable insights for fine-tuning and evaluating working postures. A visual indicator shows green when the human is balanced and red when unbalanced, supporting more accurate ergonomic analysis and posture optimization.

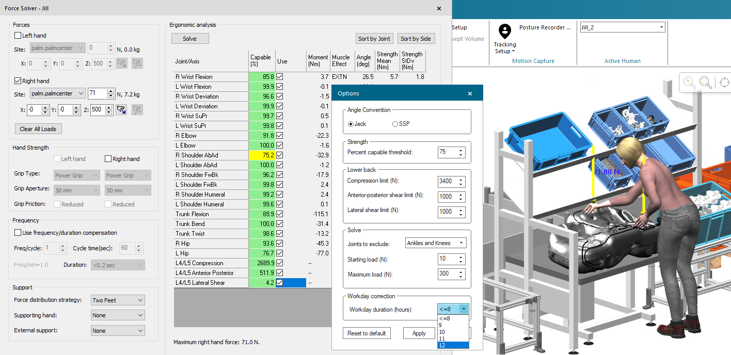

Analysis tool enhancements

The Rapid Entire Body Assessment (REBA) tool, introduced in Process Simulate version 2408, expands the ergonomic analysis toolset by enabling whole-body screening for manual tasks. REBA assesses postural demands and task forces to calculate a risk score, with separate evaluations for the left and right sides of the body. You can generate detailed reports for single postures, including analysis results and recommended actions, helping to identify and address ergonomic risks more effectively.

Improved ergonomics reporting

The latest enhancements to the Process Simulate Human analysis tools introduce improved ergonomic reporting capabilities for static strength, low back, and fatigue analysis. Reports are now generated as MS-Excel documents, featuring easy-to-interpret graphs, summarized results, and raw data for further customization. This upgrade significantly enhances the communication of findings and record-keeping, allowing you to select specific parameters, set custom thresholds, and enter personalized titles and report details. These features are available for both simulation and static studies, providing a more tailored and efficient analysis experience.

Virtual reality collaboration

As briefly featured in Process Simulate Collaboration 2408 enhancements, you can launch virtual reality collaboration in Process Simulate Collaborate, enabling seamless, immersive collaboration between colleagues and organizations worldwide, and transforming digital engineering. This solution brings the digital twin to life, allowing for virtual meetings, design reviews, and problem-solving sessions without the need for costly and time-consuming travel. The end-to-end solution simplifies file sharing and data management, while guests can easily join sessions by creating free Process Simulate Collaborate accounts, fostering global collaboration with ease.

Virtual reality sequencer kinematics

The virtual reality (VR) sequencer in Process Simulate 2408 now enables the integration of kinematic objects into VR sequences, enhancing operational playback capabilities. You can interact with elements such as opening and closing doors, securing fixtures and latches, and manipulating simple kinematic devices. Additionally, operations can be seamlessly incorporated into a VR sequence, allowing for automatic playback at specified steps. These enhancements broaden the range of real-world scenarios that can be addressed in VR, facilitating a dynamic mix of human and non-human tasks, thereby enriching the virtual training and simulation experience.

Manus glove support

The latest update to Process Simulate virtual reality now includes support for Manus gloves, enabling precise tracking of hand and finger movements. When users don active Manus gloves, a glove tracking icon appears on the controller menu, allowing for instant tracking and significantly reducing the time required for hand animation. This detailed hand tracking enhances hand clearance studies and elevates the overall immersive experience. Furthermore, Manus gloves can be integrated with full-body tracking and can grasp objects defined in the VR Sequencer. To utilize this feature, you need the Manus Core software and an HTC Vive tracker attached to the hand for accurate spatial positioning.

Virtual reality scene configuration

In the scene configuration options, there are new enhancements and custom settings that have been added to VR to support a wider range of use cases and hardware setups, including:

- Mixed reality with passthrough: You now can utilize VR headsets that support mixed reality to remove the background, creating a seamless connection between virtual and physical environments.

- loor display customization: The VR floor can be turned off, allowing for the definition of custom floor heights and styles in Process Simulate, which is particularly useful when working at atypical elevations.

- Adjustable lighting levels: You can customize the brightness of the immersive environment with lower lighting levels to optimize performance.

These are just highlights of the advancements delivered with the latest Tecnomatix release. For complete details on the new features of Tecnomatix 2408 and its supporting releases, please refer to the release notes and new features presentations offered with the software download.

Don’t forget to join the Tecnomatix public community and to explore our website for even more exciting developments in digital manufacturing.

Yours in digital manufacturing,

Kelly

(on behalf of the entire Tecnomatix product team)

You don’t have Tecnomatix software?

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)