AI Copilot: Accelerating Robotic Programming from Analysis to Commissioning

The Tecnomatix Process Simulate AI Copilot transforms how engineers interact with complex simulation environments through natural language. No more searching through menus or memorizing workflows now, simply ask. Let’s explore how the Process Simulate AI Copilot tool simplifies your workflow and accelerates productivity.

Explore how Process Simulate AI Copilot integrates AI directly into robotic programming workflows. Instead of spending hours navigating menus, manually creating collision pairs, or deciphering error logs, engineers can simply ask for what they need and receive precise, actionable results. Learn how the AI Copilot automatically inventories robots and assigns tools, generates collision pairs, and produces clear summaries of programmed operations, complete with color-coded visualization to distinguish picks, places, and advanced motions. It walks through automated reachability checks that evaluate every target, highlighting problem positions before they become commissioning issues.

And when downloads fail, AI Copilot doesn’t just report the error — it diagnoses the cause and recommends corrective steps. By offloading routine engineering tasks and exposing risks earlier, Process Simulate AI Copilot helps teams validate faster, optimize cycle time, and deliver production-ready robotic cells with greater confidence.

Watch the video to explore the step-by-step:

Robot and Tool Analysis

Manufacturing environments contain a multitude of resources that must be properly configured for accurate simulations and efficient production. Traditionally, identifying every robot and its associated tooling, and then setting up collision pairs, could consume valuable engineering time.

With the AI Copilot, these steps become effortless. Just ask it to “list all robots and their tools,” and see how it instantly inventories your industrial robots, assigns their tools, and automatically generates essential collision pairs.

Tasks that previously required detailed manual attention are now automated in seconds, allowing engineers to focus on system-level improvements rather than repetitive setup.

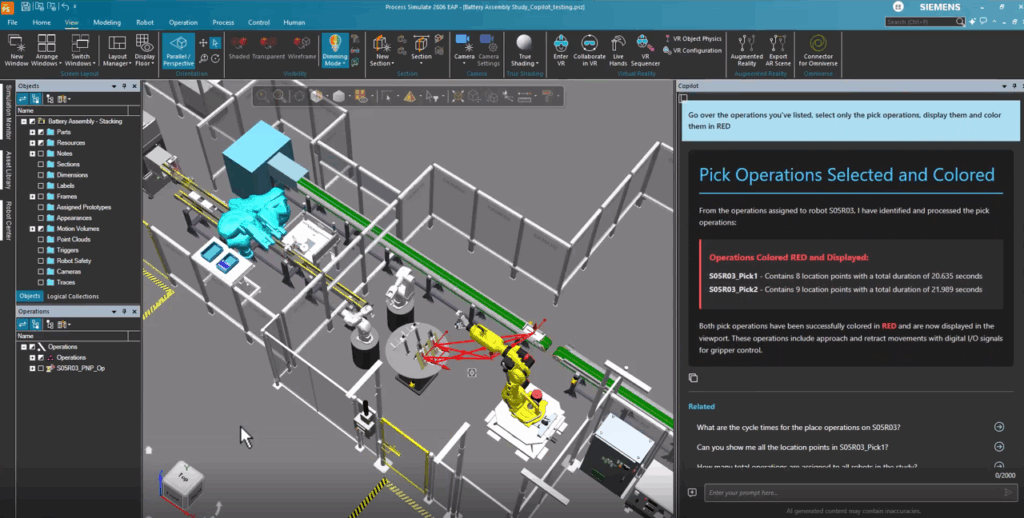

Operation Analysis

Understanding how robots are programmed to work is crucial for effective production planning. The AI Copilot provides a new level of transparency, requests a summary of all operations assigned to a robot, and receives an instant, organized list.

Go further by leveraging visualization capabilities. The Copilot can color-code operations in your 3D layout, instantly distinguishing between picks, places, and complex actions. This fast identification supports quick reviews, easier troubleshooting, and more confident adjustments.

Reachability Analysis

Accurate robot task assignment depends on knowing that each required location is physically reachable. With a simple text command, the AI Copilot runs a comprehensive reachability analysis, evaluating every target point on an operation.

Engineers receive clear, visual feedback: positions that are reachable are highlighted for confidence, while problematic targets are flagged for attention and adjustment. This proactive analysis reduces the risk of last-minute errors and promotes smoother commissioning.

Error Handling

Programming robots is a complex task, and encountering errors is inevitable-even for experienced users. What sets the AI Copilot apart is its approach to troubleshooting. If an operation download fails, the Copilot doesn’t just flag an error message-it provides a diagnosis, explains the root cause, and outlines step-by-step solutions.

Users gain not only rapid problem resolution, but also an educational experience that accelerates skill development and reduces future mistakes.

Cycle Time Optimization

Optimizing efficiency is always a primary concern in industrial production. The AI Copilot offers intelligent cycle time optimization by analyzing your current sequence and identifying improvements.

Request an optimization, and the Copilot considers robot movements before suggesting a streamlined process. Engineers often see tangible reductions in cycle time, translating directly into higher throughput and reduced production costs.

Step into the future with Process Simulate AI Copilot

The Tecnomatix Process Simulate AI Copilot represents a paradigm shift in manufacturing simulation. By combining powerful AI with deep domain knowledge, it empowers both novice and expert users to achieve more in less time. Step into the next era of manufacturing, where complexity is simplified, expertise is democratized, and productivity is unlocked for your entire team.

Interested in gaining access to the AI Copilot? Launch the free 30-day Process Simulate X Robotics trial.