Accelerating production from weeks to days: how GKN Aerospace Engine Systems soars to new heights with Process Simulate

Aerospace manufacturing leaves no room for error. Precision, coordination, and the ability to manage extreme complexity at scale are non-negotiable. Success depends on working smarter, keeping production moving while aligning people, processes, and data. That philosophy drives how GKN Aerospace Engine Systems operates every day with the help of Siemens digital manufacturing software.

As a global manufacturer of critical components for aviation, space, and defense, GKN Aerospace Engine Systems supports leading engine OEMs including Rolls-Royce, Pratt & Whitney, and General Electric. The parts are intricate, tolerances are unforgiving, and the pressure to maintain throughput never stops. Often the manufacturing operations for GKN Aerospace Engine Systems are simply too complex to program on the shop floor. Some take place in environments unsuitable for extended human presence. Others involve hundreds of paths and locations, where manual programming becomes slow, risky, and error-prone. Traditionally, programming these processes could take weeks. Manual path attribution meant repetitive effort, increased risk, and machines sitting idle while production waited.

Therefore, the GKN Aerospace Engine Systems team needed a better design-to-manufacturing approach that allowed them to program earlier, work safer, and move faster, without breaking the digital thread between engineering, manufacturing, and data.

Building an end-to-end digital manufacturing workflow with Siemens Software

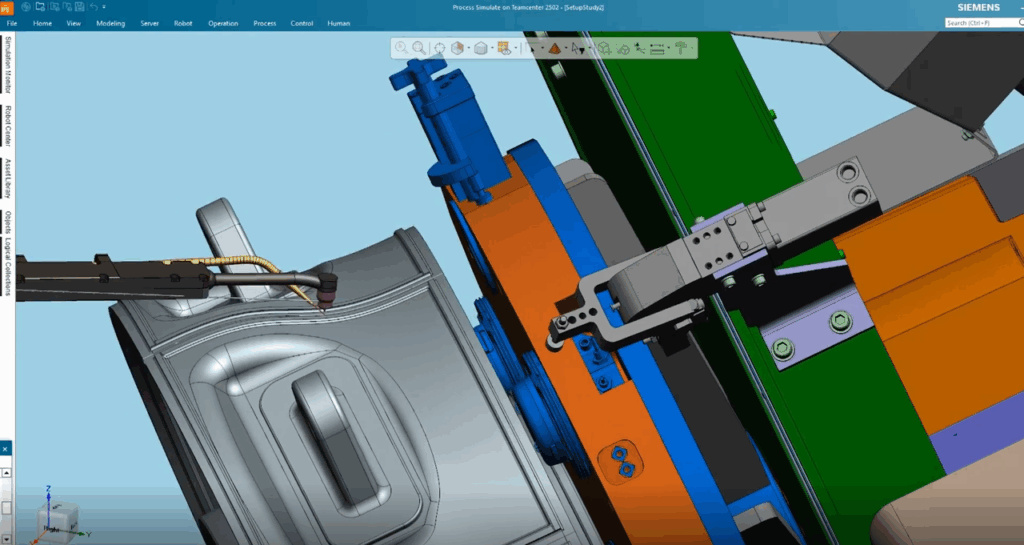

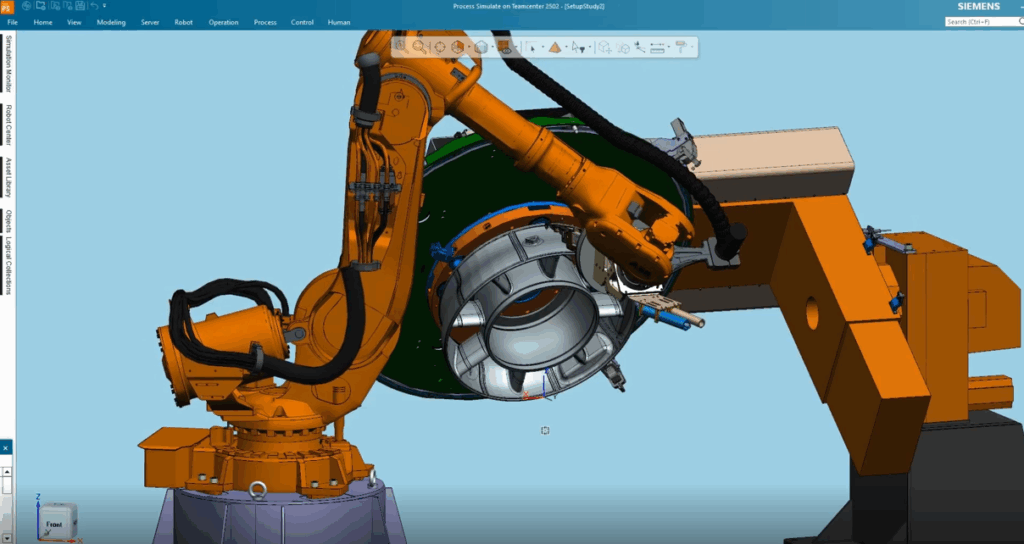

GKN Aerospace Engine Systems is a long-standing Siemens customer, using Teamcenter, Teamcenter Manufacturing Process Planner, NX CAD, NX CAM, and Process Simulate in production. The leading aviation and aerospace component manufacturer performs highly complex robotics studies, including simulation and offline programming for applications such as welding, within a managed environment that connects Process Simulate directly to Teamcenter Manufacturing Process Planner, ensuring full context and data traceability.

Teamcenter acts as the single source of truth for manufacturing data. Rather than exporting files and working in isolation, teams now operate from the same CAD models and datasets. On top of that foundation, Siemens NX CAM software is used for CNC programming, giving programmers the tools they need to handle precision machining for complex aerospace components.

When we introduced Process Simulate on Teamcenter, it felt much better knowing that we are working on the same data as all the others.”

For robotic programming and offline simulation, Process Simulate plays a central role. It enables the team to program, validate, and refine complex robotic processes in advance, away from the production line and away from environments that are not suitable for humans to work in for extended periods. The end result is a connected digital manufacturing thread that helps support GKN Aerospace Engine Systems to accelerate production from weeks to days.

[With Siemens software] we now do in hours, or a couple of days, what used to take weeks. It’s been a game changer,” says Rudqvist.

Making robotic programming predictable and repeatable with Process Simulate

GKN Aerospace Engine Systems stands out as a benchmark for what’s possible when advanced technology is paired with deep expertise. With low production volumes and frequent part variation, robotic paths often need to be adjusted for each job. Therefore, GKN Aerospace Engine Systems uses Siemens Process Simulate software to design, validate, and optimize robotic processes. Process Simulate allows these changes to be made quickly and confidently without disrupting production, while advanced path planning improves efficiency, reduces cycle time, and maintains smooth, precise robot motion throughout the process.

For example, GKN Aerospace Engine Systems standardizes robot motion with reusable path templates; enabling approach and retract movements to be applied automatically, ensuring consistency across hundreds of paths while eliminating repetitive manual effort. The flexibility of Process Simulate also supports customized robot syntax, allowing uploads and downloads to be tailored to specific manufacturing requirements.

Drawing on years of close collaboration, Siemens Digital Industries Software sees GKN Aerospace Engine Systems as an example of best-in-class simulation maturity, explains Zvika Weissman, Director of Aerospace & Defense, Digital Manufacturing Software. It is clear that GKN Aerospace Engine Systems has taken the value of Process Simulate to an entirely new level

What sets them apart is the depth of their simulation capability, a highly skilled team that has built years of experience and technical expertise. As a result, they are using the software in an exceptionally advanced and effective way,” says Weissman.

A digital foundation for faster, safer aerospace design-to-manufacturing production

By building a connected digital manufacturing environment, GKN Aerospace Engine Systems has fundamentally changed how complex robotic processes are planned and executed. What was once cumbersome and manual, is now predictable, repeatable, and performed in parallel with production.

The result is manufacturing operation that moves faster without compromising precision, where programming happens earlier, risks are reduced, and production keeps running. In an industry defined by complexity and tight tolerances, GKN Aerospace Engine Systems has proven that the right digital foundation can turn challenge into a competitive advantage.