Robot Programming and Virtual Commissioning for Electronic Assembly [WEBINAR]

Explore how virtual commissioning enables electronics manufacturers to troubleshoot, debug, and validate systems before physical hardware is installed, reducing risks and avoiding costly delays.

Today’s electronics manufacturers are facing a difficult combination of market challenges, such as constraints on labor and production resources, to meet the rapidly increasing demand for “smart” and chip-embedded technology. Electronics factories rely heavily on manual operations to assemble, test, and move components throughout the manufacturing, assembly, and packaging processes. Plant optimization and growth around manual operations is no longer capable of meeting the increasing product complexity and market demands of electronics.

In our latest webinar, explore how implementing and optimizing robotics and automation will be critical to transform traditional manual operations to meet the demands for the electronics industry.

Design, deploy and accelerate electronics assembly

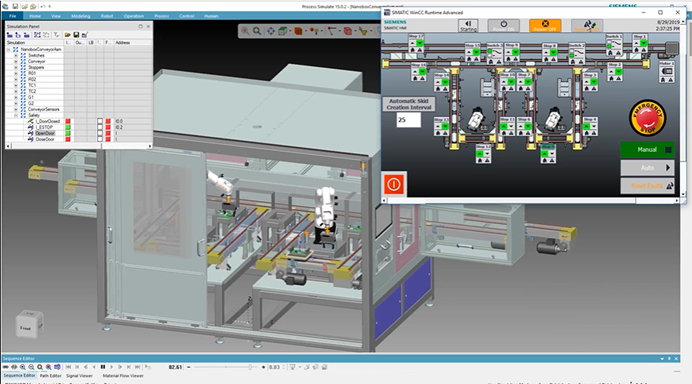

In the webinar, learn how to successfully design, deploy, and ramp up automated operations that are modular and flexible by mitigating any risks? The key is virtually simulating, validating, and commissioning before any hardware is onsite or purchased. In webinar, we will explore an end-to-end workflow for automating an electronic assembly station using Process Simulate software.

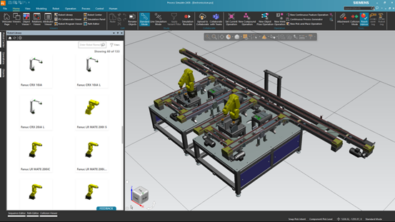

Layout Planning

The first step to simulating and validating a manufacturing process is to bring in the 3D CAD models from design. The Process Simulate Robot Library is a convenient cloud application to bring accurate robot models directly into your simulation. The layout can quickly be validated or sent back to design for revisions

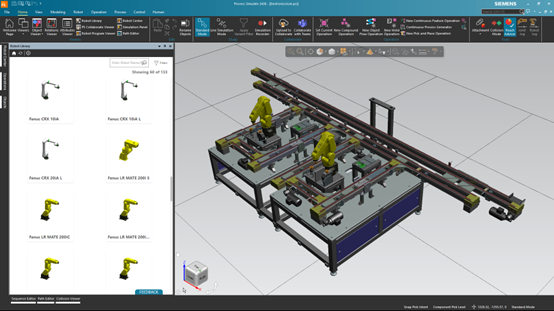

Robot Motion Planning

In step two, we can begin motion planning of the robots in the automated electronic assembly station. This includes creating the different robot operations, planning the robot path, and setting robot motion parameters. Validating a collision-free robot operation is critical to prevent equipment damage and production delays during onsite commissioning. Cycle times can be evaluated and optimized during this step to ensure requirements are met.

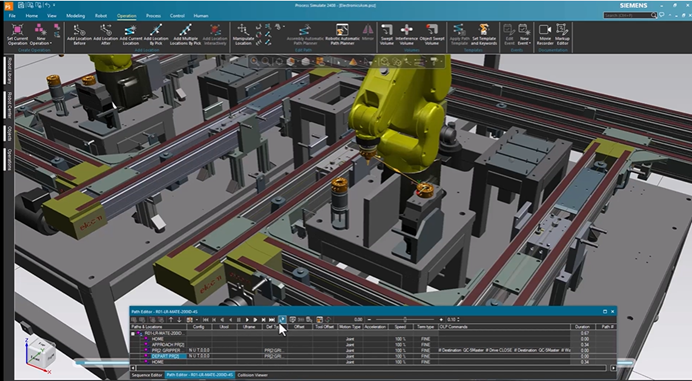

Robot Programming OLP+

In step three, we move to robot programming, or commonly called offline programming with Process Simulate. Fanuc robots are featured in this step to highlight recent enhancements around position registers, user and tool frames, and program debugging. Design revisions can quickly be implemented and re-validated. Users can troubleshoot and debug the robot program before moving on to virtual commissioning of the system.

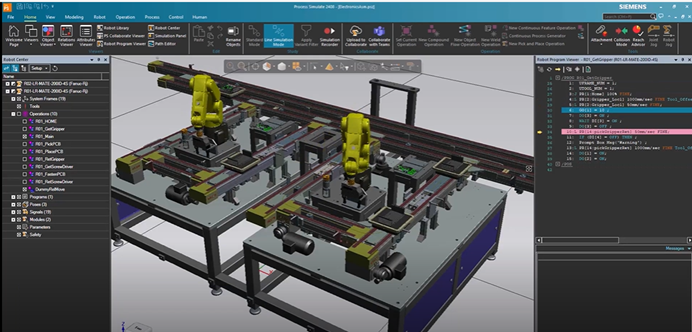

Virtual Commissioning

In step four, the electronic assembly station can be commissioned virtually to prevent costly errors before hardware is purchased or installed onsite. More detailed debugging and troubleshooting can take place during virtual commissioning. Safety systems can be validated during this step when virtually commissioning Siemens controllers (PLCs) with Process Simulate.

The successful implementation of automation and robots will be critical to enable electronics manufacturers to address market challenges, gain a competitive advantage, and meet ever-changing customer demands. Manufacturing process planning, simulation, and validation with Process Simulate reduces risk while automating manual operations in the electronics industry.