Siemens Gamesa’s digital quality journey

Teamcenter Quality empowers digital transformation

In today’s rapidly evolving energy sector, Siemens Gamesa has taken a step towards digital transformation with the implementation of Teamcenter® Quality software.

The energy sector is witnessing a transformation with the advent of digital technologies, and Siemens Gamesa is leading the way by adopting innovative solutions to streamline processes and enhance productivity. One such strategic move is the implementation of Teamcenter Quality to unify the efforts of engineering, manufacturing and quality departments.

Transformative power of Teamcenter Quality

As a cornerstone of Siemens Gamesa’s digital approach, Teamcenter Quality serves as the backbone for managing and integrating product data across various stages of the production lifecycle.

Jorge Roman, IT Solution Architect – PLM at Siemens Energy Wind Power, hosted a great presentation at Realize LIVE Europe 2025 and shared insights into the significance of Teamcenter Quality in the wind power sector. This innovative approach is transforming the way to manage product data, integrating engineering and quality teams that traditionally worked in separate silos.

Teamcenter Quality software, which is part of the Siemens Xcelerator business platform of software, hardware and services, supports a closed-loop quality (CLQ) approach from design to manufacturing. Built on the Teamcenter product lifecycle management (PLM) backbone, manufacturers can use Teamcenter Quality to leverage product and process information as well as share cross-departmental workflows to streamline core quality management processes.

“Teamcenter is our backbone for all our product data,” he explains. “Right now, we are implementing Teamcenter Quality as part of Teamcenter. So, we have all our quality processes from legacy tools into Teamcenter.”

According to Jorge Roman, this approach is revolutionary:

“Teamcenter Quality is key for us because it’s going to bring the engineering team and the quality team closer together.”

Historically according to old paradigms, engineering and quality teams operated independently, often resulting in disconnected processes and delayed workflows. This paradigm shift is now supported. Siemens Gamesa is breaking down these barriers, opening doors to integrated change management where, for instance, a design modification automatically triggers necessary quality assessments.

A strategic digital transformation

The implementation of a digital transformation strategy is reflective of commitment to refining core business workflows. Over several months, the software underwent user testing, setting the stage for its go-live.

Building on this foundation, Siemens Gamesa’s digital journey will expand beyond the initial focus on Teamcenter Quality Failure Mode and Effects Analysis (FMEA) and Teamcenter Quality Inspection and Control Planning to include integration with NX™ Inspector software, ultimately creating a comprehensive digital thread that seamlessly connects characteristics to requirement management.

Jorge notes the anticipation surrounding the transformation:

“The scope of the project has been focused on FMEAs and control plans, but in a future phase, we are also aiming to integrate our characteristics with NX via NX Inspector, so we can get them automatically into Teamcenter, as well as integrate with our requirements. And that means that once we have that achieved, we can go from characteristics all the way to requirement management.”

A transition from disconnected files to quality digital thread

The transition from traditional file-based systems to data-driven processes marked a significant shift. Through strategic collaboration, the team successfully adapted Teamcenter Quality to support industry-specific standards, such as Advanced Product Quality Planning (APQP) for wind standards.

“The most challenging thing was to convince the future end users because they were still thinking about files. That is how we were working today, and then this was a mindset change because you no longer need to think about files, you need to think about data when you have your quality digital thread.”

To ease this transition, Teamcenter Quality’s user-friendly interface played a crucial role.

As Jorge explains:

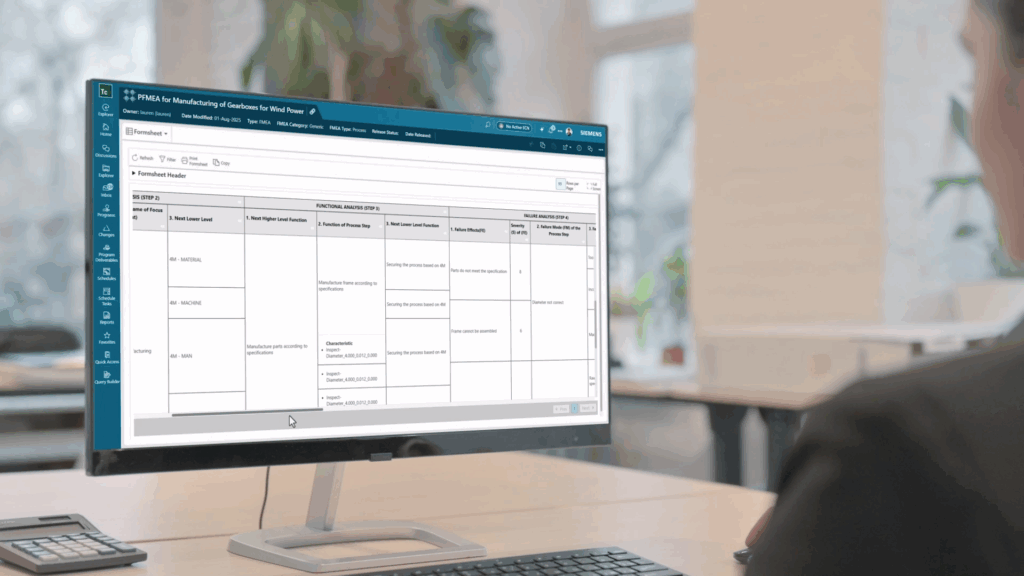

“Teamcenter quality has the form sheet view, to visualize the data like in a spreadsheet-like fashion. So, this was really like the middle step to get our end users onboard from spreadsheets

into Teamcenter quality. “

Benefits of leveraging quality data

One of the remarkable benefits is the improvement of data quality. By migrating data from legacy systems into the centralized Teamcenter backbone, Siemens Gamesa expects to foster greater collaboration and innovation, eliminating previous limitations caused by fragmented information systems. This enhancement will enable engineers to brainstorm effectively and drive more informed decision-making processes leveraging the quality digital thread.

“The return of investment is removing all the poor data quality that we have from legacy systems into a Teamcenter backbone. So, we can foster collaboration, boost brainstorming, and that possibilities were not in the legacy systems. “

Teamcenter Quality is not just a software but a strategic enabler for Siemens Gamesa, driving the digital transformation of their processes and setting a benchmark for excellence in the energy sector.

📖 Complete guide to PLM

Simplify product lifecycle management – innovate faster, collaborate better and cut costs

No matter how you choose to deploy Teamcenter,

you get the same proven solutions designed to help you innovate faster.