🚀 Ready to benefit from strategic reuse?

Classification value proposition – part 1

In today’s rapidly evolving global markets, high-value product innovations are often swiftly replicated by competitors worldwide.

Manufacturers across various industries strive to accelerate their rate of innovation, but many face significant challenges:

🚫 Unnecessary duplication and wasted effort – at every stage of the product lifecycle

🌐 Difficulties in establishing and integrating resilient supply-chain networks of global suppliers and strategic partners, which must be agile, adaptable, and capable of adjusting practices and data management strategies

📜 Struggles to meet regulatory requirements and keep up with changes

Organizations that successfully overcome these challenges are more likely to manage data effectively, gain a competitive edge, and build stronger relationships with regulators and customers

Insights from Aberdeen Group study

A study of various industry segments for business processes has shown:

🕒 80% reduction in design time for new product designs that heavily rely on reuse

🔄 30-40% of manufacturers’ parts are duplicates or have acceptable substitutes

💲 The annual carrying cost for each new part ranges from $4,500 to $23,000

📊 A part reuse strategy, including classification with advanced search tools, significantly reduces part redundancy

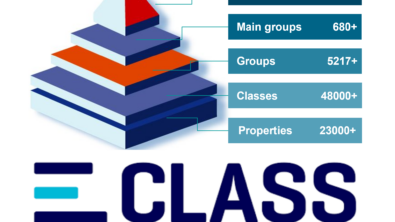

The need for classification

Organizations often resist change, but a robust reuse system, driven from the top, maximizes the reuse of a company’s product data—standard parts, technology data, designs, processes, manufacturing equipment, etc. Increased reuse results in immediate benefits and eliminates redundant processes.

✅ Tried and tested components and designs have predictable quality

🔄 Redundant processes such as quality testing and establishing new supply chains are minimized

📉 Reduced inventory and elimination of duplicates cut down recurring costs associated with carrying excess inventory

📦 Higher volumes with existing supply chains result in better costs

🚀 Fosters product innovation and faster time to market

A sound reuse strategy

Organizations need to optimize every component and process across their product portfolio. A robust reuse strategy distinguishes between simple reuse and a common platform approach.

Implementing this strategy requires careful planning, investment in classification technologies, and a commitment to changing traditional business practices.

Approach 1: standardization and reuse at the component level

- Standardization helps reduce costs with off-the-shelf standard components available in volumes.

- Benefits are constrained at the lower design process level.

Approach 2: design for standardization

- Proactively build around common platforms, reusing sub-systems and systems, not just individual components.

- Greater benefits with reuse at a higher level in the overall design process.

A good reuse strategy leveraging both approaches significantly impacts the customer’s bottom line.

In summary

Recent geopolitical turmoil has highlighted the importance of:

🔄 Optimizing reuse with existing designs and reducing inventory

🌐 Establishing diverse and resilient supply chains

🔁 Driving down costs through a circular economy

Classification is essential for establishing a healthy and resilient business amidst present risks and volatility.

📖 Complete guide to PLM

Simplify product lifecycle management – innovate faster, collaborate better and cut costs

No matter how you choose to deploy Teamcenter,

you get the same proven solutions designed to help you innovate faster.