Material Design and Management Across Disciplines with PLM

Material design and management throughout your product’s lifecycle can be critical to the success of your products. Integrating product design with materials and PLM can help to eliminate inefficiencies caused by functional boundaries and data silos, and accelerate product innovation with materials driven product design.

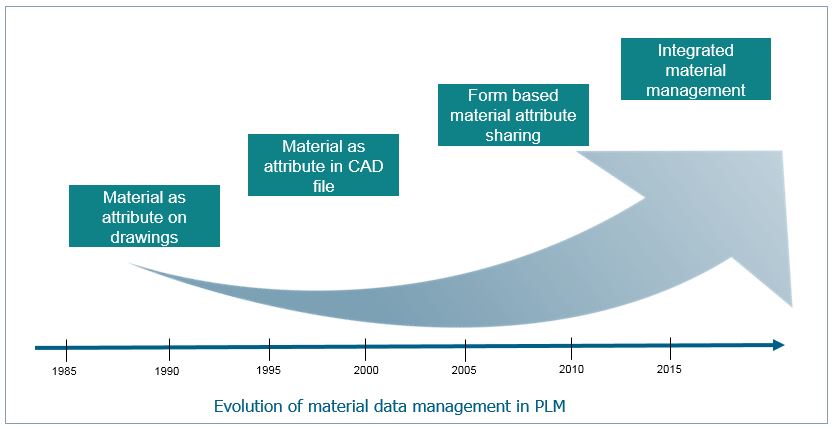

As you may know, PLM integrates people, data, processes and business systems and provides a product data management backbone for companies and their extended enterprises.As a comprehensive business tool, PLM involves the fusion of many traditional engineering disciplines such as computer aided design (CAD), computer aided engineering (CAE), computer aided manufacturing (CAM), computer aided process planning (CAPP), and sourcing. Each of these disciplines has a different perspective of the same material, leading to proliferation of functional material definitions.Each functional tool has its own way of assigning and tracking materials, leading to gaps in material data interoperability between functional tools, which in turn results in errors and duplicate work. Siemens PLM Software’s Teamcenter integrated material management is the evolution of the best practices, data representations and tools to address these issues. With Teamcenter, you can manage the lifecycle of the material, and integrate the material data right into the product development process.

Boundaries between functional disciplines disappear when managing materials data in PLM.For example, a designer in a CAD system can reach into Teamcenter to search for materials to use in designs, and once the material is selected and assigned, that material assignment is tracked and available for consumption to all users in the product lifecycle, across functions, and across tools.In the webinar titled Materials Driven Product Design and PLM, Denise Massa, Process Lead for Global Material Lifecycle Management at GM, highlights the many benefits realized by GM as a result of integrating materials with PLM to make material data available to downstream users.Speaking on the benefits of Teamcenter integrated material management, Massa states “A big win for GM is that materials can now be searched, selected and assigned based on the application or functional area.”

Managing your materials using Teamcenter can help to eliminate the boundaries between functional disciplines and systems when making material decisions. Be sure to read through our previous articles on integrated material management to learn more.

About the blogger:

Kerri Doyle is a Siemens PLM Software product marketing manager for Teamcenter Product Sustainability, Materials Management, Quality and Supplier Integration solutions. She has been in the PLM industry for over 20 years.