Tech-Clarity: configuring products to order 🎯

Customers want more choice. Manufacturers want efficiency and profitability. Balancing these goals makes configuring products to order (CTO) one of the most critical capabilities in today’s markets.

In a new interview with Tech-Clarity president Jim Brown – Rick Smith, director of engineer-to-order solutions at Siemens Digital Industries Software, shares his perspective on CTO trends and why leading manufacturers are investing in smarter ways to manage customization.

🌍 Why configuring matters

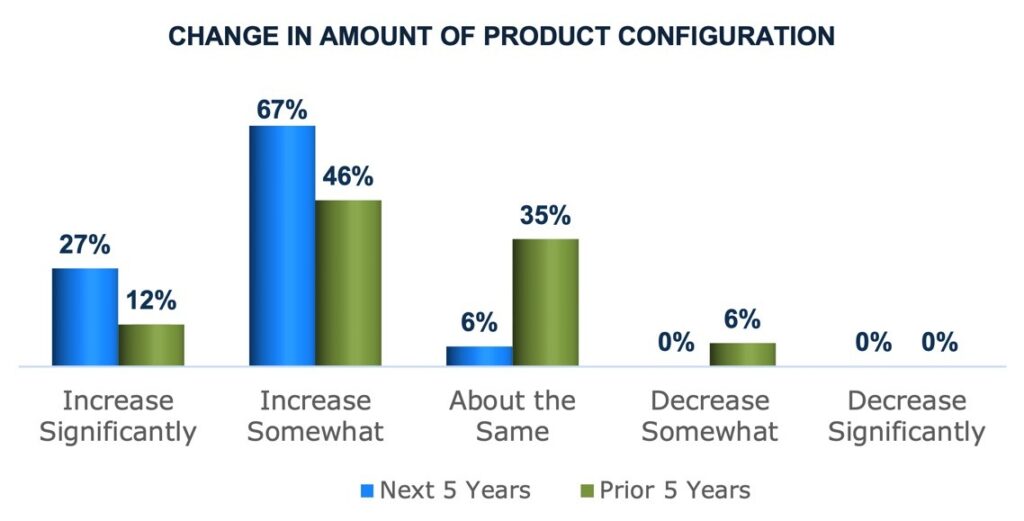

Tech-Clarity’s research shows two clear truths. Customers find configured products highly compelling, and manufacturers face major challenges delivering them. In fact, 94% of manufacturers surveyed expect customization to grow in the next five years.

Why? Because customer expectations continue to rise. From industrial machinery to HVAC systems, buyers want products tailored to their exact needs. Companies that deliver stand out from competitors and often command higher prices.

As Smith explains, sometimes it’s not optional: “By choosing to be in certain industries, you chose make-to-order. Customization is the nature of the business.”

⚡ The competitive advantage

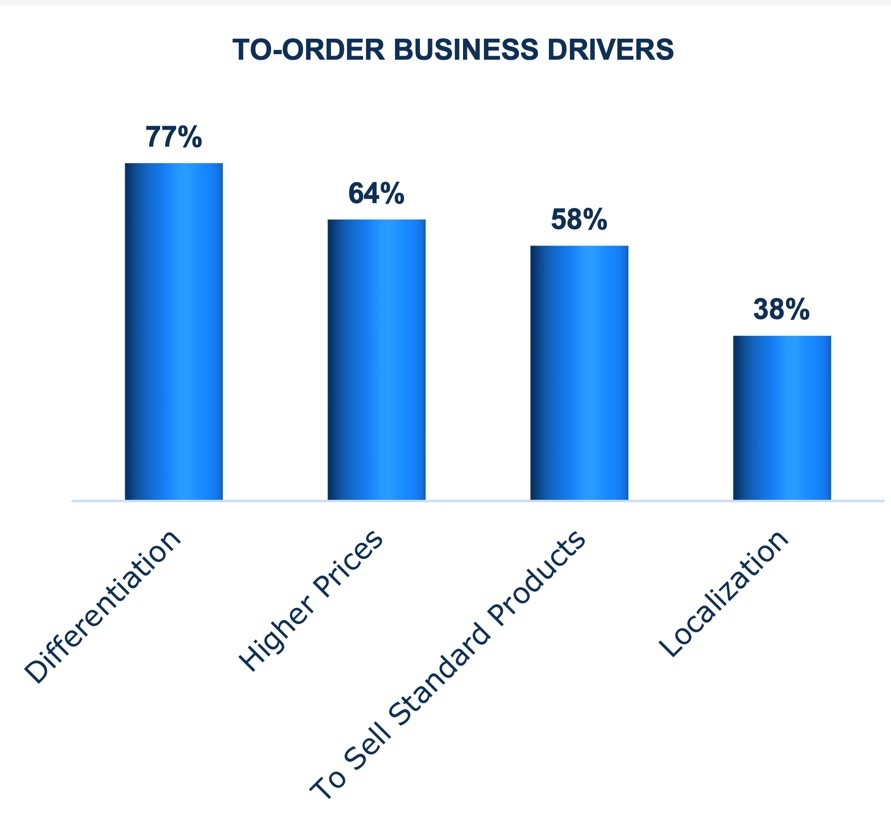

Configured products don’t just win customers — they win markets. One example from the research: a commercial air handler company that offered customization at the same price and lead time as standard products. The result? They became the global market leader.

For commoditized industries, offering customized products alongside standard ones can mean becoming the supplier of choice. The ability to say “yes” to unique customer needs often translates into larger deals, repeat business, and higher revenue.

💡 Why digitalization is key

Traditional methods — spreadsheets, manual rules, siloed tools — are no match for today’s complexity. Errors, delays, and rework drain profitability.

This is where digitalization and PLM make the difference. Siemens Teamcenter, part of Siemens Xcelerator — the open digital business platform — provides the data backbone for CTO. With Teamcenter, manufacturers can:

- Centralize configuration rules and product data

- Ensure accuracy across engineering, sales and manufacturing

- Automate routine tasks to cut engineering effort

- Reduce time-to-market by streamlining processes

As Smith notes, automation enables engineers to embed their expertise into configurators. That frees them to focus on innovation while ensuring every order is accurate and efficient.

📱 Shifting closer to the customer

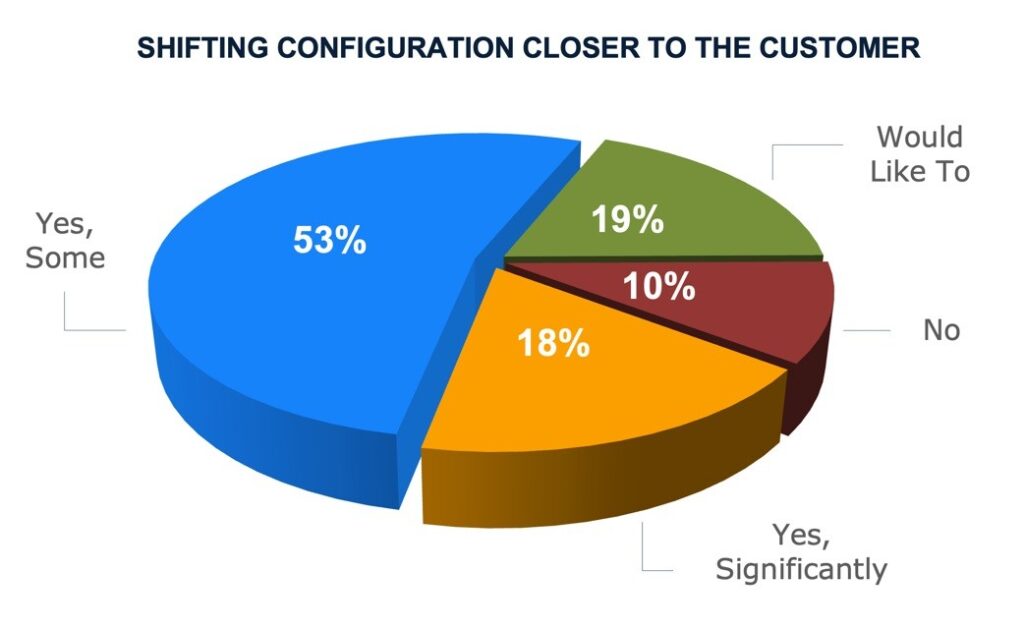

One major trend highlighted in the Tech-Clarity survey is “shifting left” — moving configuration closer to the customer. Top-performing companies are 74% more likely to do this than their peers.

Instead of relying solely on engineers, leading manufacturers are enabling salespeople, distributors, and even customers themselves to configure products directly. Mobile support and self-service portals make it easier to buy, and as Smith points out: “Customers are going to buy from whoever they can buy from the easiest.”

This isn’t just a convenience — it’s a sales strategy. Companies that make it simple to order win more deals.

🤖 The role of AI

Looking ahead, artificial intelligence promises to make configuration even smarter. Early applications include analyzing specifications, highlighting requirements, and interpreting existing configuration rules for easier reuse.

Smith is pragmatic: AI will not replace configuration engines, but it can accelerate the process.

“Well-formed configurators give you the right answer 100% of the time,” he says.

AI can help feed those configurators more efficiently, reducing manual effort and mistakes.

🗣️ Expert advice

As Tech-Clarity president and interviewer Jim Brown emphasized, manufacturers face both strategic and operational challenges in CTO. When asked what guidance he would offer, Rick Smith, director of engineer-to-order solutions at Siemens Digital Industries Software, gave three clear recommendations:

📊 Understand your market. Don’t just solve today’s problems — plan for long-term competitiveness.

👥 Choose experts wisely. Work with people who truly understand configuration.

🖥️ Invest in a platform. Configuration touches every part of the business. A proven, integrated platform is critical for scalability.

📖 Learn more

Configuring products to order is not just an engineering task — it’s a business strategy that drives growth, differentiation, and profitability.

👉 Read the full Tech-Clarity interview on LinkedIn

Start your journey to smarter, faster, and more profitable product configuration with Siemens Teamcenter.

📖 Complete guide to PLM

Simplify product lifecycle management – innovate faster, collaborate better and cut costs

No matter how you choose to deploy Teamcenter,

you get the same proven solutions designed to help you innovate faster.