Innovation and the Model Based Enterprise Effect

Light bulb moment: Visualize 3D JT data freely in a model based enterprise

Thomas Edison inspires Innovation

Thomas Edison created the first successful incandescent light bulb. For this to happen, it took numerous people seven decades of continuous work to get to the point of having a useful innovation. Historians claim up to 22 people worked on the design and function of the light bulb, and they didn’t have the benefit of shared engineering data or testing results.

We know that Edison delivered on the light bulb, but the light bulb was not initially a broadly adopted product. Without the infrastructure and shared knowledge that allowed for the distribution of electricity, the light bulb itself couldn’t compete with candles and lanterns. Edison had to make his invention one that anyone could access so it could become something that would transform the market. Players in that market needed access to the knowledge that would bring electricity to the light bulb and an unimaginable range of other new products.

Model Based Enterprise Solves Problems

Innovations that solve business problems take seed in existing knowledge, but then often cross over to other domains. Being able to understand the design and intent of existing technology allows it to be used in a broad range of applications. There must be easily accessible information available for engineers and scientists to learn from.

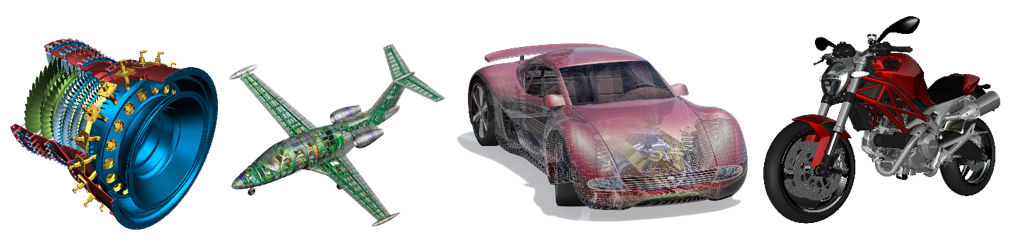

Accessing the knowledge that defines complex technology is the key to creating innovations that will solve the next big problem. Consider the knowledge companies have regarding their products today. There are huge data stores that describe how to solve problems. Before JT existed, that data was typically in a form that was difficult to access or view. Now, 3D JT data has solved that problem by democratizing engineering data.

Today, we’re in the midst of a digital Industrial Revolution. Model based designs using JT data and a model based enterprise will fuel it the way light and electricity did in Edison’s day.

The Model Based Enterprise’s Role in Innovation

The ability to visualize 3D JT data freely in an enterprise was the “light bulb” moment for model based engineering. With the adoption of model based engineering and the broad use of JT, a new range of solutions for common use cases became available. The industry has been using JT data to change its business processes for more than two decades.

JT is referred to as a “process format” by many adopters as its impact now goes well beyond visualization. Companies have used JT to completely change the ways they use data for design work. Design reviews with JT eliminated costly rework time and improved time-to-market. But that was just the beginning.

Today, JT data supports supplier collaboration, CAE results sharing, logistics and planning, digital manufacturing, packaging, shop floor mobility, paperless drawings, and virtual reality, to name a few.

These are great innovations, but these innovations are no longer enough to guarantee success in the market or give companies a competitive edge. The model based enterprise is changing the way companies answer their own “What’s next?” question.

A model based enterprise realized through JT data will enable ideas that transform the market. The industry must decide what’s next with JT. This will be the basis of what we discuss throughout this series.

In part two of this blog series, we’ll examine how model-based enterprises are the next step in the JT effort and how Siemens Digital Industries Software proposals on the JT effort from a decade ago are now in place. Stay tuned.

About the author

Mike Zink is a Senior Product Manager and Openness Evangelist with Siemens Digital Industries Software. He has more than 39 years of experience with software product development, project management, and manufacturing support. Mike currently has product management responsibility for theJT Open Toolkit, PLM XML Software Development Kit and JT2Go, the 3D data viewing tool for JT. He is also an openness evangelist and encourages openness in the industry through programs such as the JT Open Program and ISO standardization of JT. Mike has a Master’s degree in software development and management and a Bachelor of Science degree in computer science from the Rochester Institute of Technology.