PAVE360 Automotive, what is an SDV Digital Twin Blueprint and why do you need one?

The Software Defined Vehicle (SDV) is both an opportunity and a challenge for automakers. There has been an explosion in complexity of vehicle hardware and software, an increase in competition from new market entrants and now tech-savvy consumers expect product cycles more like smartphones than those associated with traditional vehicles. All these factors are placing huge pressure on development teams, who need to radically reduce time to market, whilst remaining financially competitive.

Using today’s methodology developers must wait for hardware and software availability before any kind of software integration testing can happen, a high risk strategy as many failures are detected in this period, due to unidentified system interdependencies. Shift-left software development with digital twin has long been touted as the solution, but delivering digital twin that are fit for purpose, quickly, especially at the system level is another matter.

It takes years to build and effective SDV digital twin from scratch

Getting to the starting line … fast!

Building a digital twin that caters for complexity at the system-level is a tall order, especially when new teams and new skills are being deployed. The learning curve is steep and generally available modelling solutions don’t necessarily cater for complete system simulation.

Integrating multiple disparate models and tools together from scratch can take nearly two years. Often this negates the value of a digital twin. It’s supposed to accelerate development, not slow it down. This is often the reason why digital twin programs within the automotive industry fail.

That’s why you need a pre-integrated digital twin

PAVE360 Automotive is a new concept for how to build automotive digital twin to enable the SDV. It’s a completely integrated digital twin blueprint, that provides the reference virtual hardware and software that you need to get started quickly.

PAVE360 Automotive brings that software integration phase to the beginning of the design cycle. By plugging in the digital twin to the existing vehicle network and bypassing the existing hardware and software, developers can get started fast and actually see their software driving the functions of the vehicle from the start of the design cycle. That’s an invaluable start to making sure that key sub-system interdependencies are catered for at the start when changes can be made easily, rather than at the end when engineering teams are up against hard deadlines.

So, starting with a digital twin implementing the brains of the next generation platform in the cloud, and validating in the real world, really does kick start SDV development.

What’s included in PAVE360 Automotive?

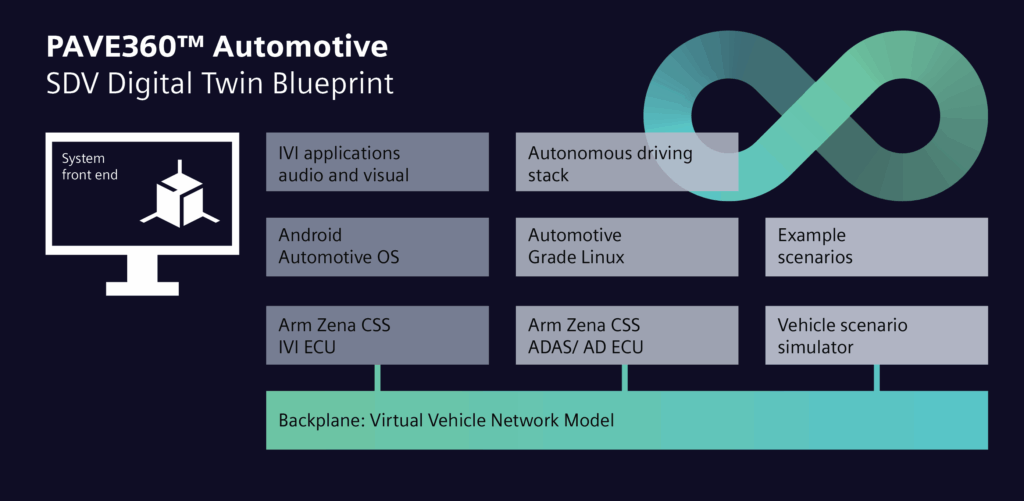

PAVE360 Automotive builds on Siemens EDA’s existing PAVE360 Digital Twin environment, a toolbox of modelling and simulation technologies. Integrating these tools together and adding automotive specific elements makes PAVE360 Automotive a complete, pre-integrated, off the shelf digital twin ready for SDV development. The pain of building the digital twin from scratch has been removed. Engineers can start doing what they really want to do from day one!

Catering for complex SDV system design

PAVE360 Automotive includes both IVI and ADAS ECU models, based on Arm® Zena™ CSS connected via a simulated vehicle network connection. Stimulus to the design is delivered through an AI-infused, advanced vehicle scenario simulator providing virtual sensor data and receiving data from the SDV electronics model.

It’s important to have a complete view of the SDV system. Next generation vehicles will have much more interaction between the ADAS and IVI domains and leverage large amounts of data passed between the two. IVI systems can process data delivered from ADAS systems and vice versa. Consider that an autonomous vehicle essentially has “eyes” and can therefore see its surroundings. That data can be invaluable in the cockpit to add huge value to applications that may want to leverage that processed sensor data.

This increasing interaction between domains means developers can no longer create software in isolation. They need to know what’s happening on the other side in order to fully validate the SDV system, not just their own isolated piece of software. Because PAVE360 Automotive includes both domains, engineers are free to focus on their own particular responsibilities but now within in the context of the whole system.

Furthermore, multiple developers operating on different domains can work on the same digital twin. System integrity can be maintained in a continuous fashion really enabling system level CI/CD flows.

How can I get close to my own ADAS and IVI design ideal?

With PAVE360 Automotive the first step in digital twin development is to bring up the pre-canned ADAS and IVI demonstration out of the box, it’s a great starting point for initial exploration. Then you can start to tailor it to your own design. You could, for example, swap out the reference autonomous driving stack with your own production software or leverage the interaction of the refence IVI software with your own production autonomous driving stack.

It’s also possible to add models for other elements that are more specific to your own digital twin needs, such as physical models for actuators, or sensor models. It’s easy to experiment by changing the configuration of the virtual hardware in the blueprint to better match your requirements.

Start with PAVE360 Automotive and then make it your own!

PAVE360 Automotive can be seen in action at CES 2026 in the Siemens booth in LVCC Automotive West Hall #4352. Find out more about the PAVE360 Automotive experience and our ecosystem partner demos.