What’s new in Opcenter Execution Process 2407

Enabling efficient collaboration and synchronization between project planning and execution

We are thrilled to announce the release of Opcenter Execution Process 2407.

This version introduces several exciting capabilities aimed at enhancing customers operational efficiency and productivity. Below are the key features of the upcoming release:

Integration with Teamcenter Easy Plan (delivered in restricted mode): Opcenter Execution Process now integrates seamlessly with Teamcenter Easy Plan. This integration enables efficient collaboration and synchronization between project planning and execution, introducing three main differentiators:

- A faster NPI (New Product Introduction) and timely reaction to change

- Collaboration between laboratory, manufacturing and execution lead to better decision making and time saving

- Improved accuracy, quality, and traceability

To enable this feature, we adopted a new model for the recipe and the work order management. Now the model and technological stack are common with Opcenter Execution Discrete allowing the management of different production processes, from chemical to mechanical assembly, with a single MES instance, supporting full end-to-end traceability of the final product.

Customers can benefit of a digital enterprise solution that offers all the capabilities of the two products in one single configuration environment, allowing the download of process recipes and discrete BOPs from Teamcenter Easy Plan and a material genealogy from the final product to the raw materials.

The enterprise solution will be enriched in the next versions with out of the box capabilities for process customers by providing:

- A native integration with Opcenter Intra Plant Logistics to harmonize and optimize production and logistics shopfloor execution

- Statistical Process Control (SPC) analysis against quality and manufacturing data to analyze data trends and patterns, make data-driven decisions, and implement continuous improvement initiatives

- A native integration with Opcenter Intelligence and Insights Hub to provide a cross-system and cross-site traceability, containment capabilities and increase manufacturing performance

This version offers a subset of capabilities based on the new model and, for this reason, it’s a restricted version for which the Product Management must be contacted.

Shopfloor connection

Integration with SISTAR BRAUMAT: Customers can now synchronize batch and MES activities with SISTAR BRAUMAT. This integration ensures accurate and real-time data exchange between systems, enhancing process and quality control.

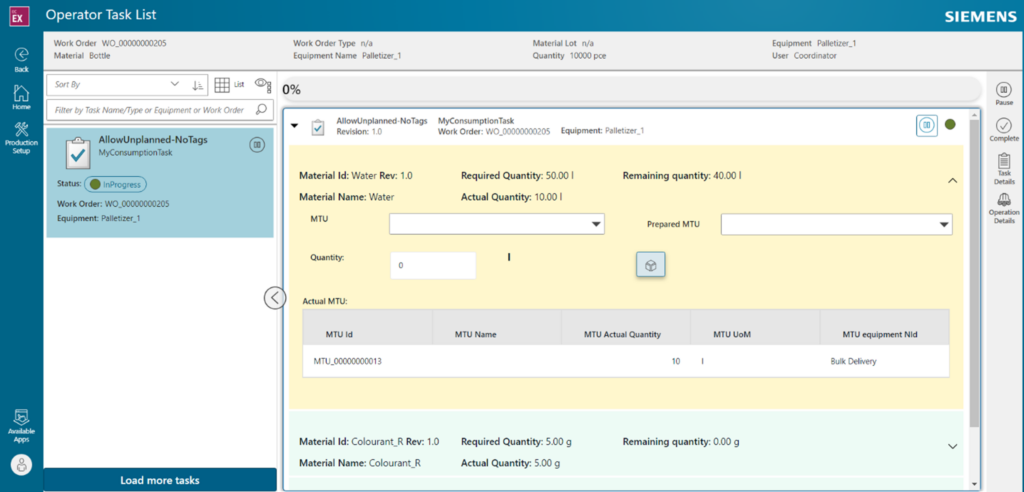

UI industry templates MX-powered

Additional capabilities for low code operation templates: Building upon previously released operation templates, we have introduced the consumption task feature. This capability guides operators in the production process, ensuring accurate material consumption and reducing errors.

New production coordinator and process engineer templates: We have introduced new templates for production coordinators and process engineers (available only for the new model). These templates enable efficient configuration of recipes and effective management of work orders, empowering users to streamline production processes.

Cross app navigation to easily navigate from the current UI application to any other deployed UI application without needing to enter the target URL or go through the login process again.

Technological upgrade: Opcenter Execution Process 2407 version comes with a technological upgrade and has been validated to be run on .NET new tech stack. Adopting the .NET stack guarantees several benefits, as for example leveraging on a multi-platform technology.

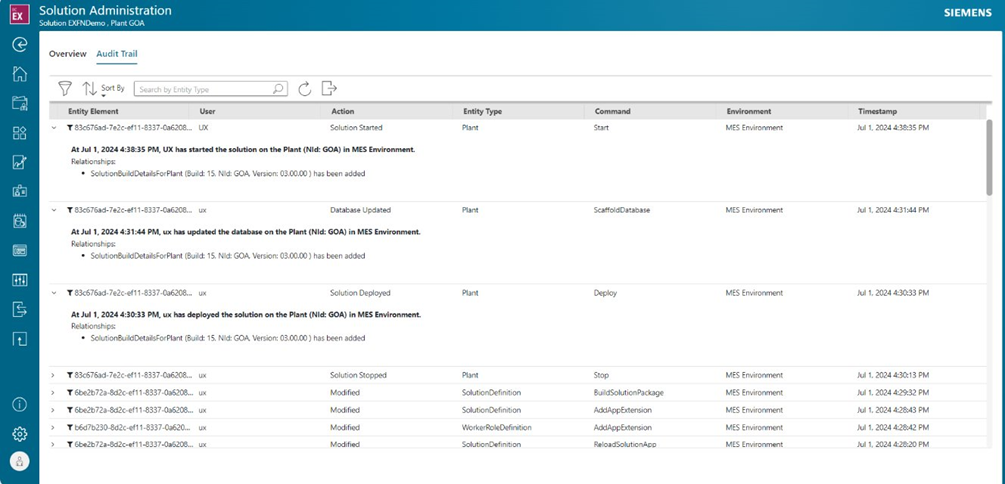

Supportability improvements in Opcenter Execution Process 2407

Host performance monitoring enhancements: The host performance monitoring has been enriched with new capabilities to continuously monitor performance metrics, and to identify areas for optimization. Customers can analyze data to improve the performance of their applications and systems.

Support of Linux operating system on UI web clients: UI web clients can run on Linux operating system by means of the Opcenter EX Process supported browsers (Chrome, Microsoft Edge).

Enable audit trail records for solution changes: To ensure proper traceability of the MES system configuration, it is now possible to track and display information in a solution studio screen about the user who made solution changes, the type of change (e.g. an app was added or removed, or a worker role configuration was modified), and the time when the change occurred.

Workflow performance improvements: The business process flow engine has been improved to obtain the best performance use cases.

Want to learn more about Opcenter Execution Process?

Using Opcenter Execution Process as a Manufacturing Operations Management (MOM) platform enables seamless integration with scheduling, quality, and manufacturing intelligence, which delivers interactive dashboards for analysis of production data.

For New Product Development & Introduction, Opcenter Execution Process enables the transformation of recipes from “generic” specifications to detailed “master” instructions, ready for order scheduling and execution. Find out more about Opcenter Execution Process.