Master yield and speed in semiconductor manufacturing

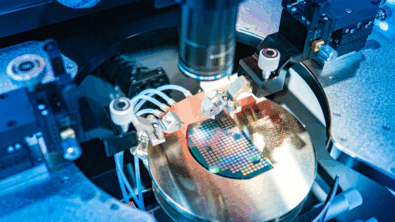

Operating at the limits of physics

Semiconductor manufacturing operates at the limits of physics. With nanometer precision as the standard, even the smallest deviation can lead to major yield losses and delayed market entry. Driven by AI, advanced computing, and electrification, demand accelerates and fabs are becoming some of the most complex production environments in the world. Industry leaders such as NVIDIA, and manufacturers like Intel push these limits every day, driving unprecedented performance requirements and placing pressure on efficiency and uptime.

Yield: the ultimate KPI across front-end and back-end manufacturing

The industry spans front-end manufacturing, where circuits are fabricated onto silicon wafers, and back-end manufacturing, where wafers are packaged and tested. Across both domains, yield is the ultimate KPI. Hundreds of re-entrant process steps, thousands of tools, and frequent changes during New Product Introduction (NPI) leave little room for error.

From design to factory floor reality

Siemens enables this through a Digital Twin approach that connects design, planning, execution, quality, and analytics across the semiconductor lifecycle (SLcM).

Using Plant Simulation, manufacturers can virtually design and validate complex plants before they are built, or changes are made. This identifies bottlenecks and reduces ramp-up risk to avoid over-dimensioning. This also predicts equipment performance and helps KPIs, leading to cost savings, energy reduction, and higher profitability.

During NPI and volume production, Opcenter Execution Semiconductor orchestrates complex production rules and frequent route changes. Our MES delivers comprehensive out-of-the-box industry functionality, high configurability, and seamless interoperability with other digital systems across the manufacturing environment. Recipe Management System (RMS), a lightweight web-based solution, centralizes, validates, and tracks every change to production recipes, enables efficient management of production recipes and ensures their correct application. To learn more about RMS, make sure to watch this video.

To fully realize a closed-loop quality approach from design to manufacturing, it’s possible to pair Teamcenter Quality software with Opcenter Execution or leverage the cloud-based Opcenter X Quality software to cover quality-relevant shop floor processes, such as performing inspections, handling non-conformances, and defining corrective actions for deviations.

On the shop floor, Insights Hub connects machines and systems into a unified operational view, enabling predictive maintenance and faster decision-making based on real-time data.

Together, these capabilities form a continuous digital thread that helps semiconductor manufacturers ramp up faster, stabilize yield, and turn manufacturing complexity into a competitive advantage.

At Siemens Digital Manufacturing, we’re proud to support semiconductor manufacturers as they turn silicon into intelligence and shape the future of the industry.

Find out more on our website.