Discover the advantages of integrating quality and PLM processes

The importance of integrating quality and PLM processes, an interesting view in new CIMdata commentary

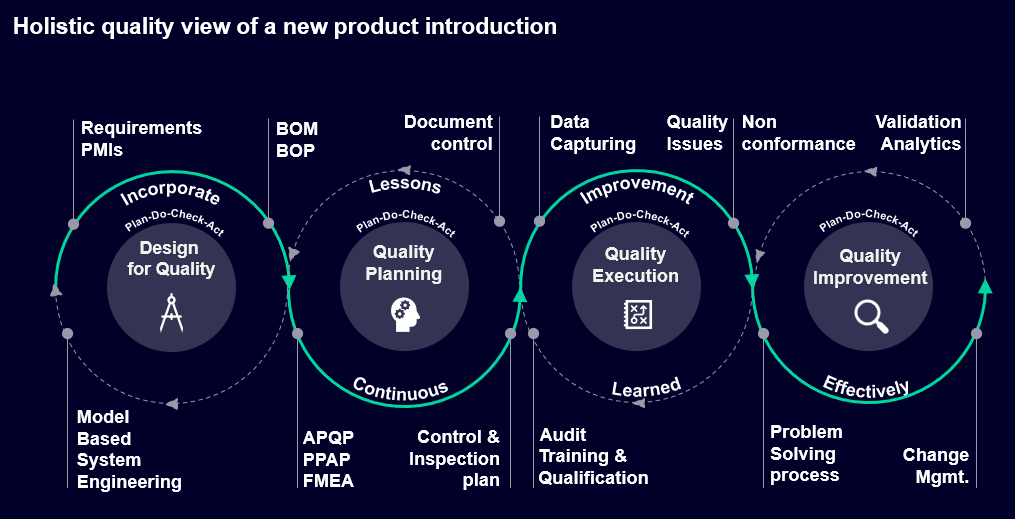

As product and process complexity continues to increase, manufacturers require quality management best practices to be applied across the whole product lifecycle. Companies must develop and redefine roles for PLM in the context of product lifecycle quality, while Quality Management Systems must expand beyond their conventional role. Quality Management Systems can no longer be strictly focused on the manufacturing repeatability and customer complaints.

CIMdata released a new commentary “A broad approach to Quality Management. Closed-Loop Quality Solution Leverages Teamcenter Backbone”. This commentary is aimed at establishing an in-depth analysis of the quality paradigm in the connection with Digital Threads, with special focus on importance of integrating quality and PLM processes seamlessly across the product lifecycle. Analysts provide guidance about the importance of integrating quality and PLM processes seamlessly across the product lifecycle. Digital transformation programs need to embed the advantages of a new paradigm for Quality Management.

In the analysis, CIMdata specialists detail a set of key points:

- Evaluation about Quality Management responsibilities and how it is expanding across the value chain. It is fundamental to consider the quality paradigm in connection with digital twins and the digital thread.

- Ability to leverage on the concept of Bill of Quality (BOQ) to face challenges related to increased product complexities. Siemens’ view of BOQ encompasses all of the necessary information that describes a product from the quality processes perspective, but integrated into the product development (BOM) as well as the product manufacturing (BOP).

Learn more about advantages of the new paradigm for Quality Management by leveraging Siemens Quality Management solutions.