AVAILABLE NOW! Opcenter Execution Process 4.2

A new version of our MES for Process Industries is available: Opcenter Execution Process 4.2.

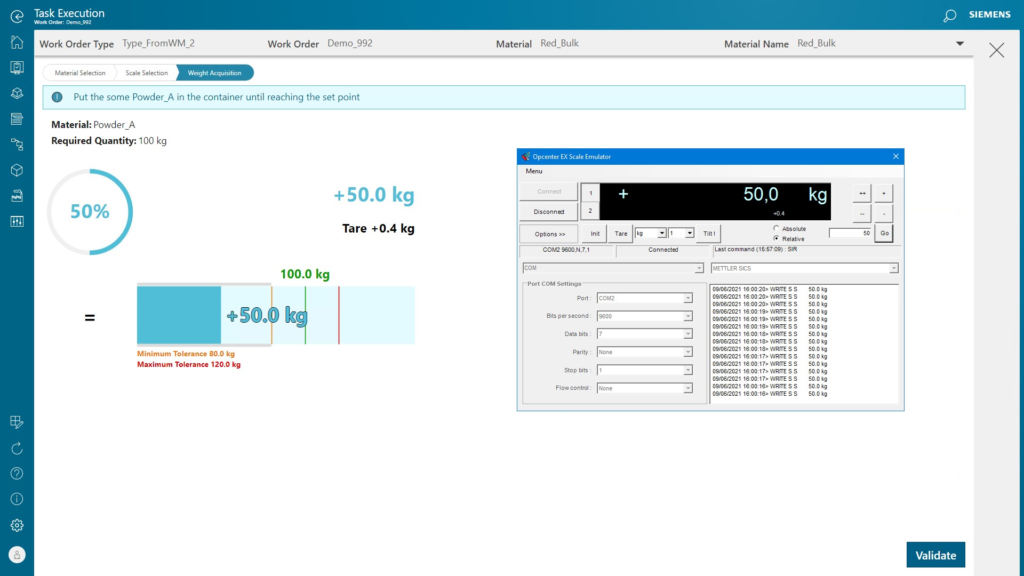

Opcenter Execution Process 4.2, which is part of the Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, provides out-of-the-box user interface (UI) components for weighing and dispensing activities, including material selection with barcode scanning, scale selection, scale taring, weight acquisition and scale release. The consistent user experience guides the operator through the entire process, repeating its flow until all actions have been completed.

These components are called step templates and their sequence and transitions can be rearranged to better fit your weighing process. For example, if you don’t need to control the release of the scale at the end of the weighing, you can simply remove that step from the flow.

Opcenter Execution Process 4.2 brings you the following benefits:

- Provide state-of-the-art platform to deploy predefined industry templates

- Translate business processes into codeless business logic with an open engineering and execution platform

- Synchronize business with manufacturing, including integrating automation and batch execution

- Deliver just-in-time and intuitive execution support for complex shop floor operations and seamless user experience for production operators

- Integrate quality tests in shop floor processes, including lot quality control and information exchange with laboratory personnel

- Facilitate advanced planning and scheduling of operations and resources, optimizing equipment use and increasing efficiency

Opcenter Execution Process 4.2 also brings user experience enhancements, with a revamped page for the management of bill-of-materials (BOM). Many options are available to view and manipulate the data, including an advanced filter builder. The new UI also adds new capabilities: Now it is possible to select multiple BOMs and export them into a package, which can be easily imported into another environment, making it ideal for your project’s development and testing phase in case you need to quickly iterate over small changes in your engineering data. The new audit-trail tab displays all the modifications performed on the BOM, detailing who did the change, when it was done and what were the old and new values in that change. The user experience improvements also apply to the use of the BOM items on other pages. For example, it is now much easier to select items from the BOM to create requirements for a work order or work master.

This release also improves the visualization of work-in-process (WIP) by providing new tabs that aggregate the consumed and produced material quantities in each context. For example, the production order page is enriched with the new tab, which lists the consumed and produced materials of all the work orders related to the production order. In a glance, the user can see the aggregated quantities (required versus actual) of every material from all the work orders combined. At the work order page, a similar view is available, displaying the aggregation of materials from all the relevant operations.

Already using Opcenter Execution Process? See what’s new in version 4.2.

Want to learn more? Using Opcenter Execution Process as a MOM platform enables seamless integration with scheduling, quality, and manufacturing intelligence, which delivers interactive dashboards for analysis of production data. For New Product Development & Introduction, Opcenter Execution Process enables the transformation of recipes from “generic” specifications to detailed “master” instructions, ready for order scheduling and execution. Find out more about Opcenter Execution Process.