A Vision for Sustainable Urban Agriculture: Industrialization through Digitalization

In the heart of America, a revolutionary concept in urban agriculture is taking shape. Vertical Harvest, under the visionary leadership of co-founder and CEO Nona Yehia, is emerging as a groundbreaking force in the controlled environment agriculture (CEA) sector. What began as a mission to connect sustainable food production with social responsibility has blossomed into a transformative model for urban farming, demonstrating how technology and human-centric design can create lasting impact in our communities.

“In my career, I really found that food was the strongest connection to human and environmental health, and that’s how I became a vertical farmer,” reflects Nona Yehia, encapsulating the profound purpose that drives Vertical Harvest’s mission. The company’s innovative approach to urban agriculture isn’t just about growing food—it’s about nurturing communities, creating opportunities, and revolutionizing how we think about sustainable food production in urban environments.

Scaling Innovation in Controlled Environment Agriculture

Vertical Harvest faced a pivotal challenge in their growth journey: how to scale from their initial success in Jackson Hole, where they produced 100,000 pounds of produce annually, to a dramatically larger operation in Maine. The new facility, a 50,000-square-foot building housing an impressive 200,000 square feet of growing area, represented not just a physical expansion but a quantum leap in operational complexity.

The challenges were multifaceted and interconnected. In their original facility, the team relied on a patchwork of basic tools—Excel sheets, paper logs, and manual tracking systems—to manage their operations. While these systems were adequate for their initial scale, they became significant barriers to growth. “With that kind of scale, we obviously can’t use paper logs,” Yehia explains, highlighting the urgent need for technological evolution.

The complexity of managing a vertical farm of this size presented several critical challenges:

- Coordinating multiple growing zones across vast vertical spaces

- Managing precise environmental controls for optimal plant growth

- Tracking and optimizing resource usage, including water and energy

- Coordinating a diverse workforce, including team members with disabilities

- Maintaining consistent product quality while scaling operations

- Integrating various systems and ensuring seamless communication between them

Most crucially, Vertical Harvest needed a solution that could serve as the digital backbone of their operation while remaining adaptable to their unique needs. To this point Yehia emphasizes the importance of finding the right technological partner:

As a small business owner, we want something that’s lightweight, that’s scalable, and can be customized to us

Watch the full interview to see how Vertical Harvest transformed their operations with Opcenter X.

Creating a Digital Ecosystem for Urban Agricolture

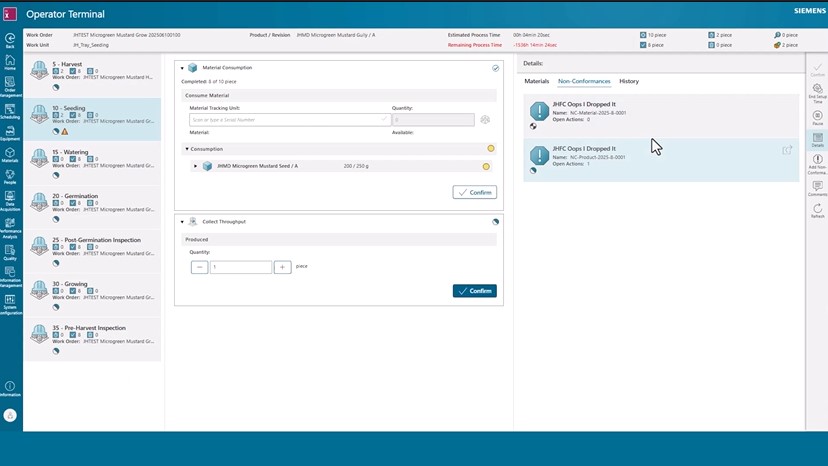

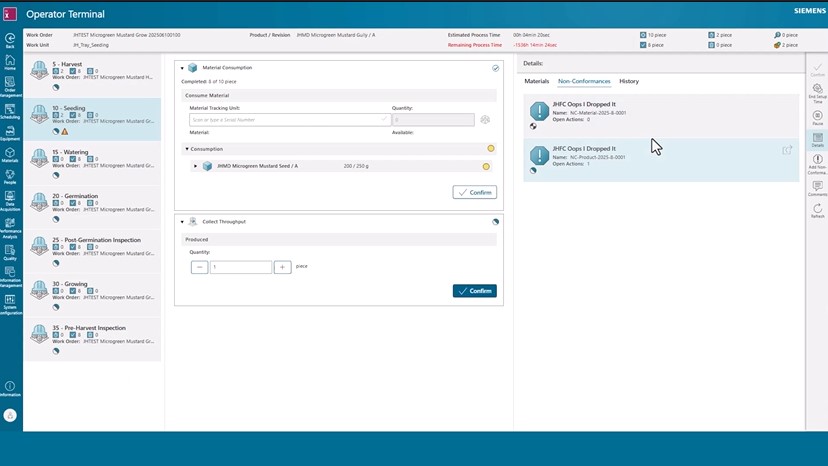

The search for a solution led Vertical Harvest to Siemens Digital Industries Software, specifically the Opcenter X platform. This partnership marked the beginning of a comprehensive digital transformation that would revolutionize their operations. “Siemens has been the right partner for us to be able to customize to exactly the workflow that we need,” Yehia affirms, highlighting the crucial alignment between Vertical Harvest’s needs and Siemens’ capabilities.

The implementation of Siemens Opcenter X transformed Vertical Harvest’s operations into a sophisticated, digitally-enabled ecosystem. Capturing the fundamental shift in their operational approach, Yehia explains:

Opcenter X was a digital brain for us, a digital floor manager that can work remotely.

This digital transformation manifested across multiple dimensions of their business:

Integrated Operations Management

Where once there were disparate systems and manual processes, Opcenter X created a unified digital environment.

“Being able to have a single point where you can access information, understand what you’re supposed to do that day, to have that coordinated in one place is really critical“

Yehia emphasizes. This centralization eliminated the information silos that had previously hindered efficiency and scalability.

Data-Driven Decision Making

The platform revolutionized how Vertical Harvest approaches performance metrics and business intelligence.

“What’s really important to us as operators is really managing yield, but in order to be a successful business, we also have to manage margins.”

The system provides comprehensive tracking of crucial metrics:

- Revenue per square foot

- Production yield per square foot

- Energy consumption patterns

- Water usage optimization

- Overall operational efficiency

Industrialization of Urban Agriculture

Perhaps most significantly, the digital transformation enabled Vertical Harvest to pioneer the industrialization of vertical farming while maintaining their commitment to sustainability and social responsibility. “What Opcenter X has allowed us to do is really work towards the industrialization of this industry. What are the best practices? How do we record them? What is a holistic system so that the machine, the ecosystem as a whole, operates in an entirety?” Yehia explains.

Growing Futures: The Human Side of Digital Transformation

What truly sets Vertical Harvest apart is their unique approach to workforce development and social inclusion. The digital transformation story here isn’t just about technology—it’s about people. “My co-founder, who was trying to solve the problem of employment, to connect a population that has a really high unemployment rate to businesses who needed consistent, reliable workforces to run their business, and that’s where Vertical Harvest’s mission became, not only to grow food, but to grow futures,” Yehia shares.

The implementation of Siemens Opcenter X played a crucial role in supporting this mission. With 40% of their workforce identifying with physical or intellectual disabilities, the digital platform needed to be both powerful and accessible. The system’s intuitive interface and customizable workflows enabled Vertical Harvest to:

- Create tailored work instructions

- Develop adaptive training programs

- Support diverse learning styles

- Enable independent task management

- Foster workplace confidence and autonomy

“If you can really customize employment so that you are supporting people’s abilities and utilizing technology to bring out those abilities, not only build a culture that is really strong, you’ve also created opportunities that weren’t there before,” Yehia concludes.

It nourishes you. It nourishes your family, it nourishes your community, and that is the real promise of technology.

Nona Yehia, Co-founder and CEO, Vertical Harvest Farms

Watch the full video interview

Discover how Siemens Digital Industries Software can help transform your operations. Contact us today to learn more about our solutions for sustainable business growth.