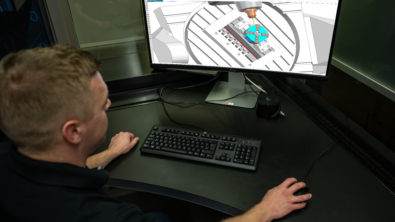

Video: NX 11 for Manufacturing – Highly efficient production machining

View our new video, “NX 11 for Manufacturing – Highly efficient production machining,” narrated by Tom van ‘t Erve, Director of Development, NX CAM Prismatic Parts Machining, Siemens PLM Software.

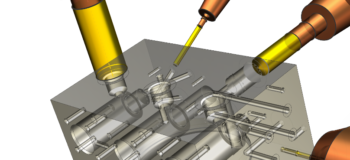

I want to take the opportunity to present the highlights of NX CAM in the prismatic machining area. We’ve introduced the brand new hole making operation that we have built that from the ground up. It will give you at least a sixty percent reduction in NC programming time. We’ve done that by introducing geometries selection. Automating that using feature recognition and by doing that we are basically limiting the amount of keystrokes that people have to input, the amount of geometry picking they have to do. By doing that we are able to give that such a significant improvement.As part of the new hole making operations, we’ve actually introduced a couple of great new capabilities. One of them is dealing with intersection holes, crossing holes, cooling holes, waterline holes, where drilling one hole impacts teardrops in the second one – we now deal with that completely automatically. We’ve introduced deep hole drilling as a separate operation that requires separate processes, separate tools. In addition to the regular chamfering operations we’ve introduced back counter syncing, and further optimization across multiple groups of operations for drilling, hand hole milling, chamfer milling, and fret milling, all of those contributing to a great set of new capabilities in this new release.

To learn more about the new capabilities in NX for Manufacturing, visit our web pages.