The Value of NX for Part Manufacturers – One Integrated System

Extensive NX customer loyalty and longevity of continued use by a large percentage of our customer base is something that we’re very proud; however we don’t talk about much.We know that changing systems is hard and typically costly for any company. But we also know that the vast majority of our customers continue to invest in ongoing maintenance and support for NX.In this blog series I will explain what drives the rationale for such loyalty to our flagship product, NX CAM software.

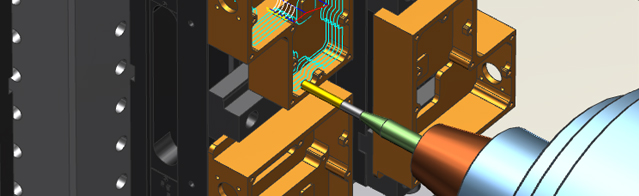

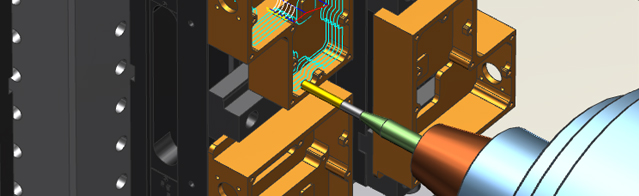

All programmers using NX CAM have access to an extensive and technically advanced part and assembly modeling system. Immediately this set it apart from the computer-aided manufacturing (CAM) solutions that evolved as “CAM only” solutions. The trend to offer integrations with widely used 3rd party computer-aided desgin (CAD) packages has helped those systems, but NX has had the benefit of evolving hand in hand with a completely common technology base applied from design through manufacturing applications. This has, for example, enabled the “master model” concept to be a fully practical capability, always available as a powerful enabler for model based engineering.

For vertically integrated companies this may facilitate an easy connection between design and manufacturing engineering, extended now to support for PMI-based automation. But as we know, in manufacturing engineering most NC programmers spend a significant amount of time working with model geometry. They may be repairing imported 3rd party models, they may be creating stock or stage models, or modeling work-holding, tool assemblies or even preparing full 3D assembly models of machine tools. They may be making changes to the part geometry and needing to update machining operations on the fly.

In NX all this and much more is available to the user in one integrated system. And these aren’t just basic CAD functions.NX CAM users have direct access to the latest in Synchronous Modeling technology. Even dumb solids imported via IGES from other systems can be manipulated, stretched, or dynamically adjusted to add stock or close off openings. With the latest releases of NX the NC programmer equipped with NX CAM can utilize our new Tolerant Modeling, opening up the ability to work with models that combine surfaces and solids just as if they were full 3D solid models.

There are many more reasons why NX is a system of choice for so many part manufacturers. I will provide some further examples in the next blog in the “Value of NX for Part Manufacturers” series.

Read the 2nd blog in the Value of NX for Part Manufacturers series here.

Try NX CAM software free for 30-days.You can register here and start experiencing the power of NX today.