The Future of NX Manufacturing: Modular, Cloud-Connected and Service-Led

In the world of advanced manufacturing, change isn’t coming, it’s already here. And with tools like NX X Manufacturing, companies are uniquely positioned to lead this transformation. But capitalizing on the full potential of digital manufacturing means going beyond traditional CAD/CAM. It requires integrating systems via APIs, embracing the cloud, and prioritizing services as a core value driver.

NX X Manufacturing: A Digital Backbone

Siemens NX X Manufacturing has become an end-to-end solution for manufacturers aiming to optimize everything from design to production. With powerful capabilities in computer-aided manufacturing (CAM), additive manufacturing, and robotics programming, NX enables intelligent, automated workflows.

Real transformation happens when systems talk to each other, data flows freely, and insights are shared in real time.

Why APIs are the connective tissue of Smart Manufacturing

Today’s production environments are complex ecosystems. ERP, MES, PLM, and supply chain systems must work in harmony to enable speed, flexibility, and resilience. That’s where APIs (Application Programming Interfaces) come into play to develop seamless integrated apps that help manufacturers.

Connecting NX to other systems via APIs unlocks new possibilities:

- Real-time updates between design changes and production tooling

- Seamless integration with quality systems, reducing defects and rework

- Predictive maintenance using data from machine sensors tied to the digital twin

APIs empower manufacturers to build modular architectures where tools can evolve without disrupting the entire system. It’s the difference between isolated automation and true digital continuity.

The Cloud: From Infrastructure to Innovation Platform

Traditionally, manufacturing software lived on-premises. But the cloud has flipped that paradigm. NX’s integration with cloud-based platforms allows teams to:

- Collaborate globally on a shared digital twin

- Scale compute power on demand for simulation and verification

- Store and process large volumes of production data for AI-driven insights

Cloud isn’t just about offloading infrastructure, it’s about enabling agility, innovation, and resilience. Manufacturers who shift their NX workloads to the cloud gain not only speed, but also the ability to experiment, iterate, and improve continuously.

From products to services: The new competitive edge

The shift to digital manufacturing doesn’t stop at the factory floor. It extends into how products are delivered, monitored, and monetized. Manufacturers are increasingly embedding software, connectivity, and services into physical products.

With NX and its API cloud integrations, companies can:

- Provide digital services like remote monitoring and optimization

- Offer subscription-based models for equipment usage or upgrades

- Continuously update machines in the field, just like software

This service-first mindset opens the door to recurring revenue, stronger customer relationships, and differentiated value in an increasingly commoditized world.

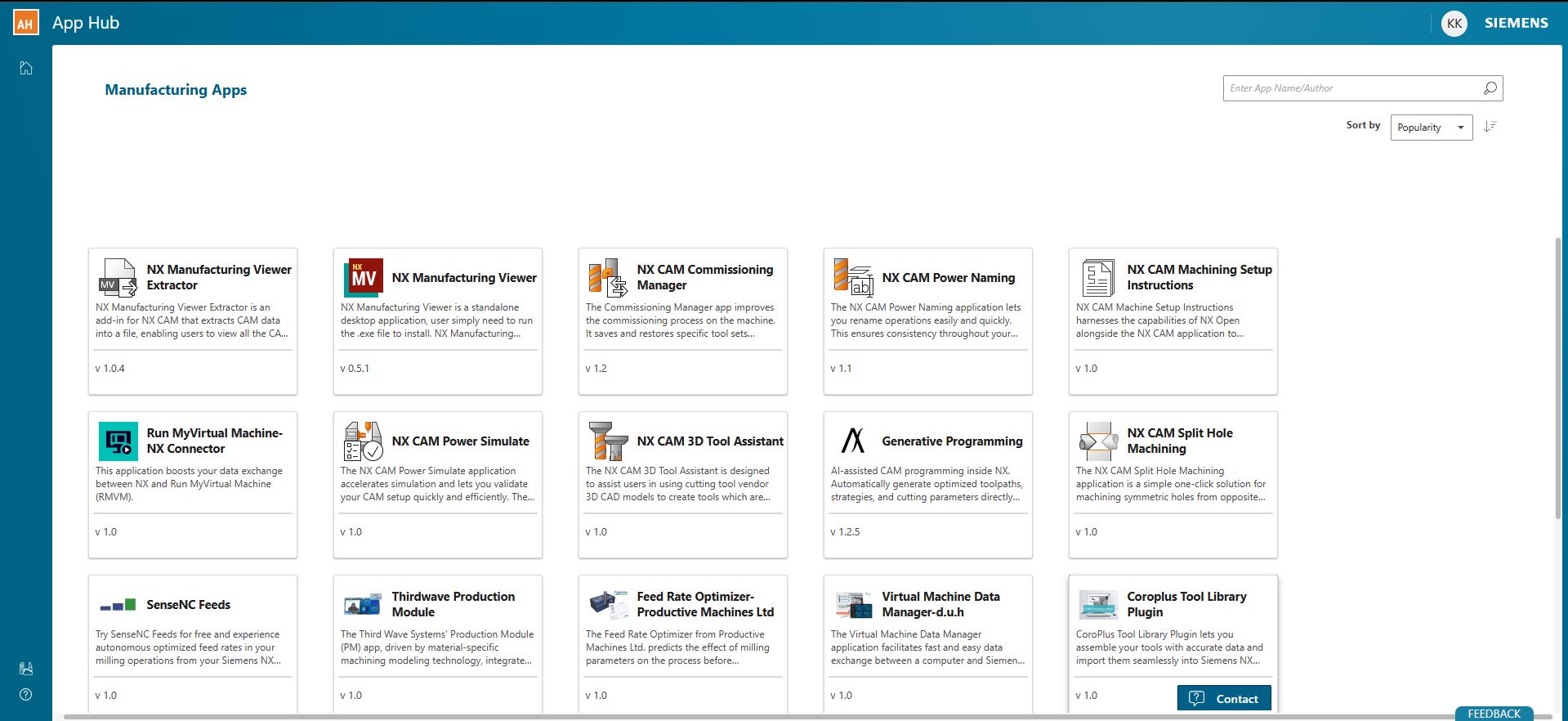

NX CAM App Hub and Post Hub extending manufacturing capabilities

Cloud-based platforms like the newly released NX App Hub combine the advantages of cloud services and apps to seamlessly integrate with NX X Manufacturing and beyond. This environment helps organizations accelerate productivity while accessing applications tailored to specific industry needs.

With NX App Hub, the ecosystem continues to expand with third-party applications that enhance part manufacturing workflows. For example:

- NX CAM Power Naming helps simplify and standardize naming conventions for part programs, ensuring consistency across projects.

- NX Manufacturing Viewer provides lightweight, cloud-based viewing of manufacturing data, making collaboration more efficient across engineering and shopfloor stakeholders.

- NX CAM Commissioning Manager streamlines the commissioning process for CNC programs, enabling faster validation and smoother machine setup.

These are only a few of the solutions available. Many more apps on the NX App Hub deliver flexible and scalable capabilities that adapt to industry-specific requirements.

Additionally, Post Hub is a modern, cloud-based solution for postprocessing that streamlines the generation of production-ready CNC programs. It provides access to over 1,100 Siemens-supported postprocessors directly from within NX CAM software.

Post Hub can be accessed either through its dedicated website or directly within NX CAM. This flexibility allows users to search for and download postprocessors in the way that best fits their workflow, making CNC program generation more efficient.

Final Thought: The future is Integrated

NX X Manufacturing is no longer just a solution, it is a catalyst for transformation. To realize its full potential, manufacturers need to think bigger:

- APIs connect capabilities.

- The cloud accelerates innovation.

- Services deliver long-term value.

By combining these forces, manufacturers can build agile, responsive, and intelligent operations that not only survive disruption, but lead it.