Siemens Partners with Lambda Function to Explore AI-Assisted CNC Programming For NX CAM

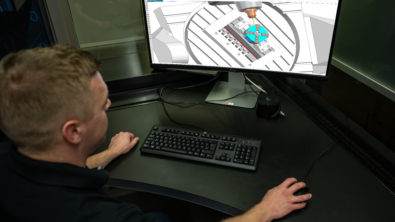

Siemens is excited to introduce the integration of Lambda Function’s solution, an AI-powered add-on, now available with Siemens’ NX CAM software. This collaboration highlights Siemens commitment to driving innovation through strategic technology partnerships.

In part manufacturing, every minute on the shop floor matters, and so does every decision that goes into programming a part. What if your CAM software could not only recommend the best tools and parameters for the job, but also learn and improve with every cycle? That’s the vision behind our new technology partnership with Lambda Function.

Lambda Function is working to redefine CNC programming by tapping into one of manufacturing’s most valuable yet underutilized assets: machining data. Their AI-assisted software is targeting to simplify CAM programming, eliminate adverse events caused by process variability, and automate continual learning. By merging CNC machining know-how with artificial intelligence, Lambda Function is developing solutions that offer the potential to augment the technical workforce and push productivity to new heights.

NX CAM looks toward AI Machining for potential productivity improvements

The power of NX CAM is already well known in the manufacturing industry. Our part manufacturing community continues to validate this leadership, with NX CAM ranked as the #1 computer-aided manufacturing software on trusted review platforms like G2.

Partnering with innovative technology providers like Lambda Function has the potential to further strengthen the value we deliver to our end users — bringing the benefits of AI-powered NC programming into NX CAM. At the heart of this collaboration is a commitment to continuously enhance part manufacturer productivity with faster programming, more consistency, and greater intelligence.

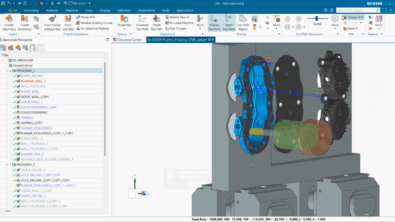

With the new Lambda Function plug-in for Siemens NX CAM, AI capabilities are embedded directly into your NX CAM workflow:

- Select optimal cutting tools based on material, geometry, and machining strategy

- Leverage adaptive machining parameters tuned for productivity and reliability

- Access suggested toolpaths informed by learned best practices

- Benefit from closed-loop learning that continually adapts based on shop floor feedback

Our mission is to equip part manufacturers with breakthrough technologies that accelerate part production while improving quality and efficiency. We partner with the most forward-thinking technology providers, like Lambda Function, to offer our customers every advantage in the competitive manufacturing landscape,” said Armin Gruenewald, Vice President at Siemens Digital Industries Software

Unified Innovation Through the Siemens Xcelerator Platform

This collaboration highlights the openness of the Siemens Xcelerator platform — our platform that enables dynamic partner ecosystem designed to integrate specialized solutions from leading technology innovators. By fostering interoperability, we give our customers the freedom to adopt advanced capabilities without disruption, ensuring they can leverage the best software tools available to run their end-to-end operations.

For users with an existing NX CAM account, explore the integration of Lambda Function’s solution, an AI-powered add-on, now available on Siemens App Hub.

Explore how the Siemens NX CAM integration with Lambda Function can help you improve your machining performance, shorten lead times, and compete more effectively in the global market.