Step-by-step guide: implementing CAM software in your manufacturing workflow

A disconnected manufacturing workflow creates inefficiencies at every stage of part manufacturing—from design and programming to machining, inspection, and quality control. Integrating CAM software is no longer optional; it’s essential for eliminating inconsistencies and reducing rework.

Without a seamless connection between these stages, fragmented processes, data silos, and excessive manual intervention slow production and drive up costs. A well-implemented CAM software system automates CNC programming, optimizes machining operations, and integrates with the other manufacturing systems—ensuring precision, efficiency, and scalability.

This guide outlines a step-by-step approach to CAM software implementation, key considerations, best practices, and how Siemens NX CAM simplifies the process for a more efficient and connected manufacturing workflow.

Step 1: initial planning and goal setting

Before diving into the implementation process, defining clear objectives for CAM software adoption is crucial. What specific improvements are you looking to achieve? Are you aiming to reduce lead times, increase machining accuracy, or enable more complex manufacturing capabilities? Are programming bottlenecks slowing down machining? Are manual processes leading to errors and inefficiencies? Identifying these challenges ensures that CAM software implementation is targeted and effective.

Take the time to assess your current manufacturing processes and identify areas where CAM software can make the most significant impact. This initial planning phase will serve as a roadmap for your implementation journey, helping you stay focused and on track.

Double-check:

- Have key pain points in the current part manufacturing workflow been identified?

- Are there specific goals for reducing lead times, improving machining accuracy, or increasing automation?

- Have the challenges of manual processes and programming inefficiencies been considered?

- How will CAM software fit into existing workflows without creating disruptions?

Step 2: assessing system compatibility and integration requirements

One of the most critical aspects of implementing CAM software is ensuring compatibility with your existing systems and software. Before selecting a CAM solution, evaluating its ability to integrate with manufacturing systems is essential. A disconnected system can create data inconsistencies, version control issues, and inefficiencies across design, programming, and production.

Seamless integration with CAD, PLM, MES, ERP, and QMS systems enables real-time collaboration and a more efficient part manufacturing process. Siemens NX CAM stands out in this regard, offering robust integration capabilities with a wide range of CAD and PLM systems, ensuring a smooth flow of data and minimizing operational disruptions.

Double-check:

- Is the CAM software compatible with existing CAD and PLM systems?

- Can it integrate with MES, ERP, and QMS to streamline workflows?

- Will data flow seamlessly between design, machining, and production teams?

- Does the system support standardized file formats to prevent version mismatches?

Not all CAM software is created equal, and it’s essential to choose a solution that offers the features and capabilities that align with your specific manufacturing requirements. Consider factors such as multi-axis machining support, adaptive milling techniques, and toolpath optimization when evaluating different CAM software options.

Step 3: selecting the right CAM software and features

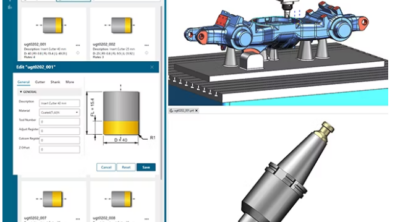

Choosing the right CAM software goes beyond just compatibility—it must also align with specific manufacturing needs. Advanced features such as automated toolpath generation, multi-axis machining support, and AI-driven machining strategies can significantly enhance efficiency and precision.

Deployment and license management are also key considerations. On-premises CAM software solutions provide direct control over software and infrastructure, making them a preferred choice for organizations with dedicated IT management. Cloud-based CAM solutions, on the other hand, enable easier deployment, seamless updates, and scalable access across teams and locations. Siemens NX CAM supports both deployment models, ensuring manufacturers have the flexibility to choose the best approach for their operational requirements.

Double-check:

- Does the CAM software offer the required machining capabilities?

- Can it scale to accommodate future manufacturing needs?

- Does it include simulation and validation tools for process optimization?

- Are AI-driven programming and automation capabilities available?

- Does the licensing model provide flexibility based on business needs?

- Is cloud-based access an option for simplified deployment and maintenance?

Experience Siemens NX CAM firsthand with a 30-day free trial—explore its full capabilities and see how it transforms part manufacturing.

Step 4: training and development

Implementing new CAM software is only half the battle; ensuring that your team is proficient in using the software is equally important. Develop a comprehensive training and onboarding strategy to help your users get up to speed quickly and efficiently. This may include a combination of in-house training sessions, online courses, and hands-on workshops.

Training should cover toolpath generation, machining strategies, simulation, and post-processing. Siemens provides interactive training, certifications, and access to user communities that offer a wealth of knowledge to support your team throughout the implementation process and beyond.

Double-check:

- Has a structured training plan been developed?

- Are training resources, online courses, and certifications available?

- Is ongoing support accessible for troubleshooting and workflow optimization?

- Does the program include hands-on exercises for practical learning?

Step 5: testing and pilot implementation

Before rolling out your new CAM software across your entire manufacturing operation, it’s wise to conduct thorough testing and initial implementation on a smaller scale. This allows you to validate, identify and address any potential issues or compatibility problems before they impact your full production workflow.

Set up test projects that represent a cross-section of your typical manufacturing tasks, and have your team work through them using the new CAM software. This hands-on experience will not only help users become more comfortable with the software but also provide valuable insights into any areas that may require additional training or optimization.

Collaboration between manufacturing engineers, CNC programmers, and machine operators is essential during this phase to ensure toolpaths are optimized, machining parameters are correctly configured, and the system performs as expected. Testing should also assess integration with CAD, PLM, and other connected systems to confirm seamless data flow. Adjustments made during this stage will help refine processes before full deployment.

Double-check:

- Have test projects been set up to validate the CAM software in real-world scenarios?

- Were machining parameters and toolpaths validated during testing?

- Did the testing phase identify any integration challenges with other systems?

- Were adjustments made based on user feedback before scaling implementation?

- Does the pilot implementation confirm expected efficiency improvements?

Step 6: full-scale deployment and optimization

Once the testing phase is complete and necessary adjustments have been made, it’s time to move forward with full-scale implementation. Roll out the CAM software across your part manufacturing operations, ensuring that all users have access to the resources and support they need to succeed.

To achieve a smooth transition, establish standardized workflows, refine tool libraries, and validate machining strategies to maximize efficiency. As the software is deployed, continuously monitor its performance and gather feedback from users. Siemens NX CAM offers powerful analytics and reporting tools that help track key metrics and identify areas for improvement. By taking a data-driven approach to optimization, CAM processes can be fine-tuned to achieve greater efficiency and productivity gains.

Double-check:

- Has the CAM software been fully integrated into production workflows?

- Are standardized processes and best practices established?

- Is system performance being monitored for ongoing improvements?

- Are there mechanisms in place to capture user feedback and refine workflows?

Case Study: NX CAM implementation at W.A. Pfeiffer

W.A. Pfeiffer, a precision parts manufacturer, enhanced its production efficiency by implementing Siemens NX CAM alongside other digital manufacturing solutions. By integrating CAM software with their existing PLM system, the company achieved significant productivity gains:

- 50% reduction in programming time through seamless CAD-to-CAM integration.

- 30% improvement in machining efficiency with optimized toolpaths and process validation.

- Minimized errors and rework by leveraging digital process validation.

- Accelerated production cycles with automated toolpath generation.

- Seamless transition from design to manufacturing through a connected workflow.

This step-by-step approach to CAM software adoption showcases how a well-planned implementation can drive measurable efficiency gains in part manufacturing.

Conclusion

Implementing CAM software in your manufacturing workflow can be a game-changer, enabling you to optimize processes, reduce lead times, and enhance overall productivity. By following the step-by-step guide outlined in this article and considering the benefits of Siemens NX CAM, you can ensure a smooth and successful implementation that delivers tangible results for your business.