Hybrid manufacturing advancements: industry insights with Big Metal Additive

As an application engineer for Siemens Digital Industries Software, supporting the team behind the Multi-axis Deposition application in NX for Manufacturing has been a rewarding experience. My passion has deepened over the years in additive manufacturing, which led to the purchase of desktop-sized 3D printers for personal use, enabling the creation of custom tooling and fixture designs for home and workshop projects. While these small-scale applications serve practical needs, industrial additive operations in NX are designed for complex part manufacturing.

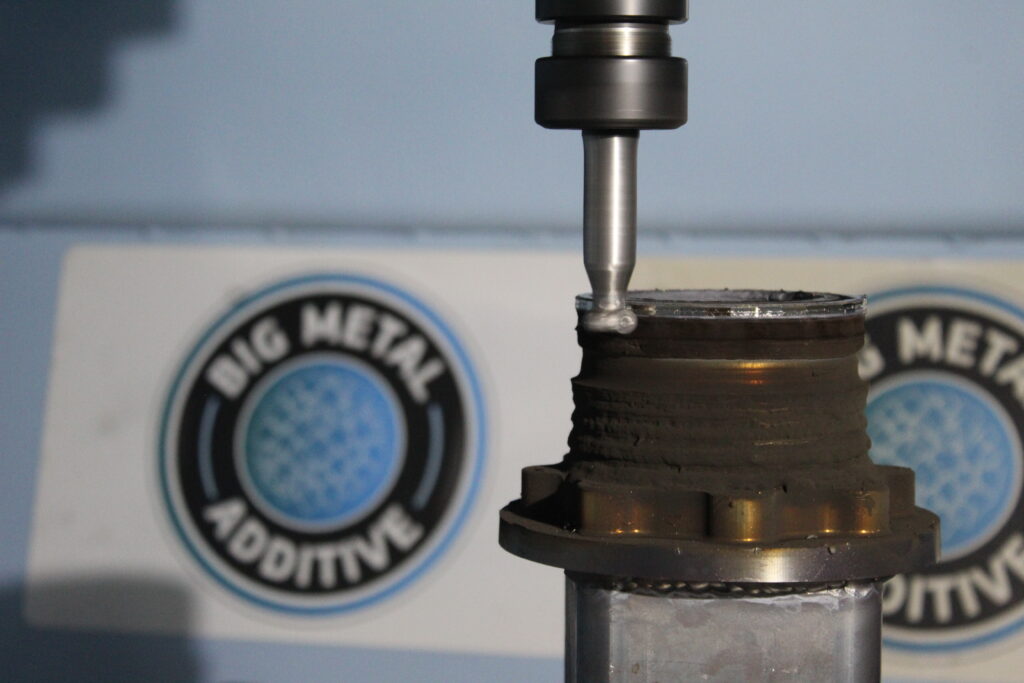

I recently had a visit with a major industrial additive manufacturing customer, Big Metal Additive (BMA) who uses Siemens Additive Manufacturing software. BMA is an additive manufacturing machine shop in Denver, Colorado specializing in metal 3D printing and integrates welders with 5-axis CNC mills to explore new frontiers in manufacturing. Their work is often pushing new boundaries, serving both private companies and government agencies to replace traditional processes, build intricate geometries and conduct material testing. BMA’s use case with Siemens Multi-Axis deposition application provided valuable insights into the evolving landscape of hybrid manufacturing. This visit not only highlighted the cutting-edge processes shaping the future of additive manufacturing, but also reinforced key industry trends that are transforming modern machine shops.

Inside Big Metal Additive: a pioneer in hybrid manufacturing

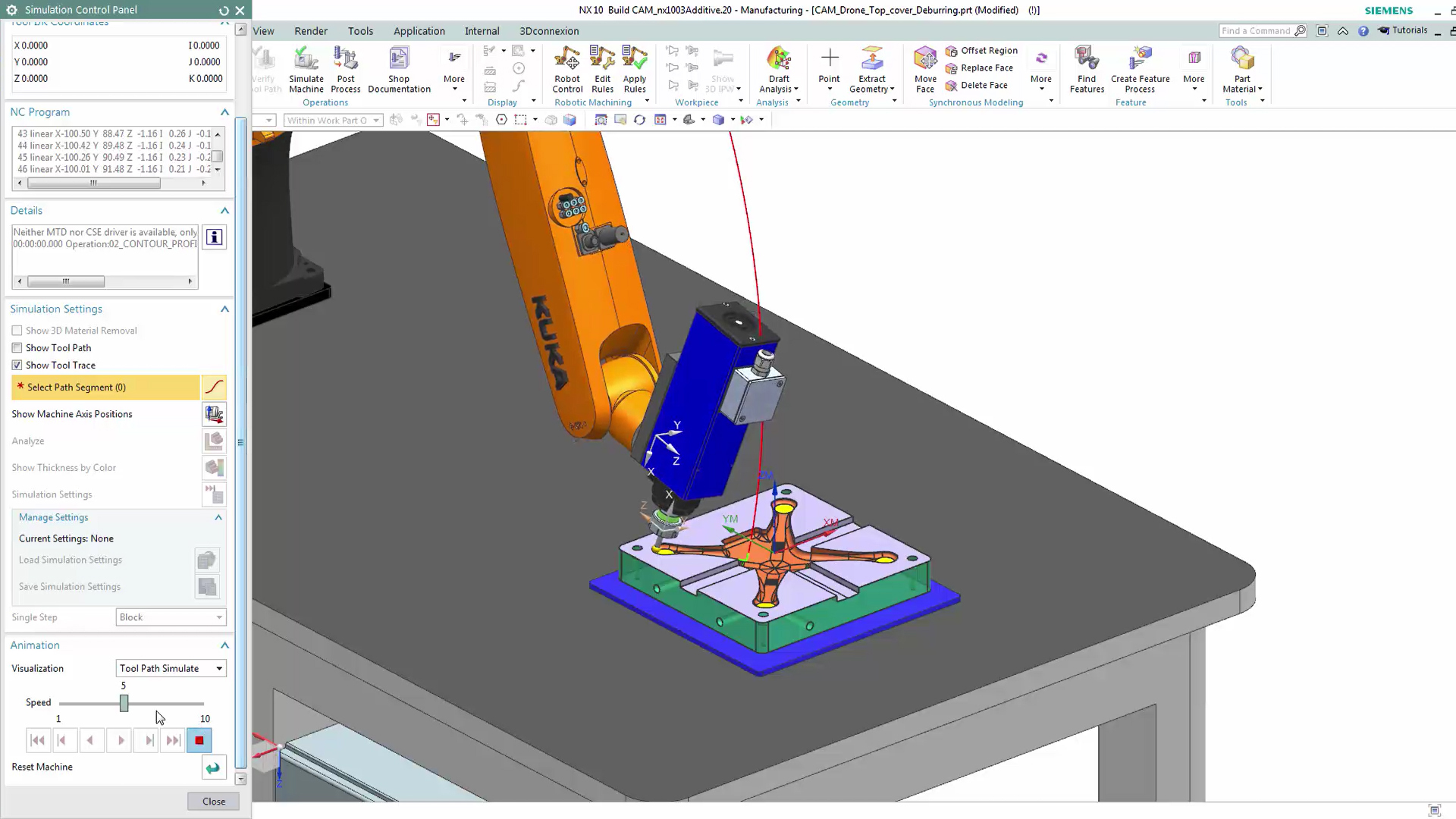

Multi-axis printing pushes the boundaries of additive manufacturing, enabling the production of highly complex geometries once deemed impossible. By eliminating gravity as a constraint, designs remain true to intent without the need for compensatory adjustments. The increased freedom of motion moves manufacturing beyond planar layering, allowing for continuous deposition paths that enhance stress characteristics. Additionally, multi-axis printing isn’t limited to small-scale applications — robotic arms enable scalable production, opening new possibilities for larger, more intricate components.

The evolving role of manufacturing engineers

Since the early days of the Multi-axis Deposition application, BMA has leveraged its advanced additive manufacturing capabilities. In this hybrid manufacturing blog series, join me as we explore two key takeaways with a pioneering manufacturer like BMA, including the involving nature of manufacturing jobs, where employees develop a diverse skill set rather than specializing in a single role. This is an important topic as an agile workforce not only benefits business operations, but also fosters a culture of continuous learning for employees eager to expand their expertise.

The value of an end-to-end hybrid manufacturing solution

The second topic in my blog series discusses the advantages of having hardware and software capable of managing all hybrid operation types within a single software environment for additive manufacturing (AM), computer-aided manufacturing (CAM), and data management – an end-to-end solution, such as Siemens NX for Manufacturing, helps companies like BMA accelerate machining efficiency and profitability.

The knowledgeable and enthusiastic engineers at BMA provided valuable insights, enhancing both software testing approaches and the ability to assist other manufacturers adopting cutting-edge part production technologies. With rapid advancements in hybrid machining, the future of manufacturing holds exciting possibilities, and continued innovation in machine shops will only push these boundaries further. I look forward to sharing these insights with you so stay tuned to learn more.