From Insight to Action: Siemens Advanced AI Solutions Featured in Advanced Manufacturing

Siemens was recently featured in Advanced Manufacturing, a leading industry publication, spotlighting how its AI-driven solutions are transforming modern production environments. In the article, The practical side of AI, the Advanced Manufacturing publication highlights Siemens leading role in advancing digital manufacturing, particularly through its AI Production Copilot and NX CAM Copilot, showcasing how manufacturers are driving measurable improvements in productivity, quality, and operational resilience across the industry.

As Director of Marketing for the digital manufacturing division of Siemens Digital Industries Software, I contributed my insights into how Siemens AI is driving measurable improvements in manufacturing. As manufacturers navigate digital transformation, the question is no longer whether to adopt AI, but how to implement it strategically for maximum impact. Explore the article and learn how Siemens AI drives productivity gains by automating tasks and providing intelligent assistance, leading to higher output per engineer and operator. Gain insights on how AI is driving measurable improvements in manufacturing.

Siemens AI technology that delivers impact

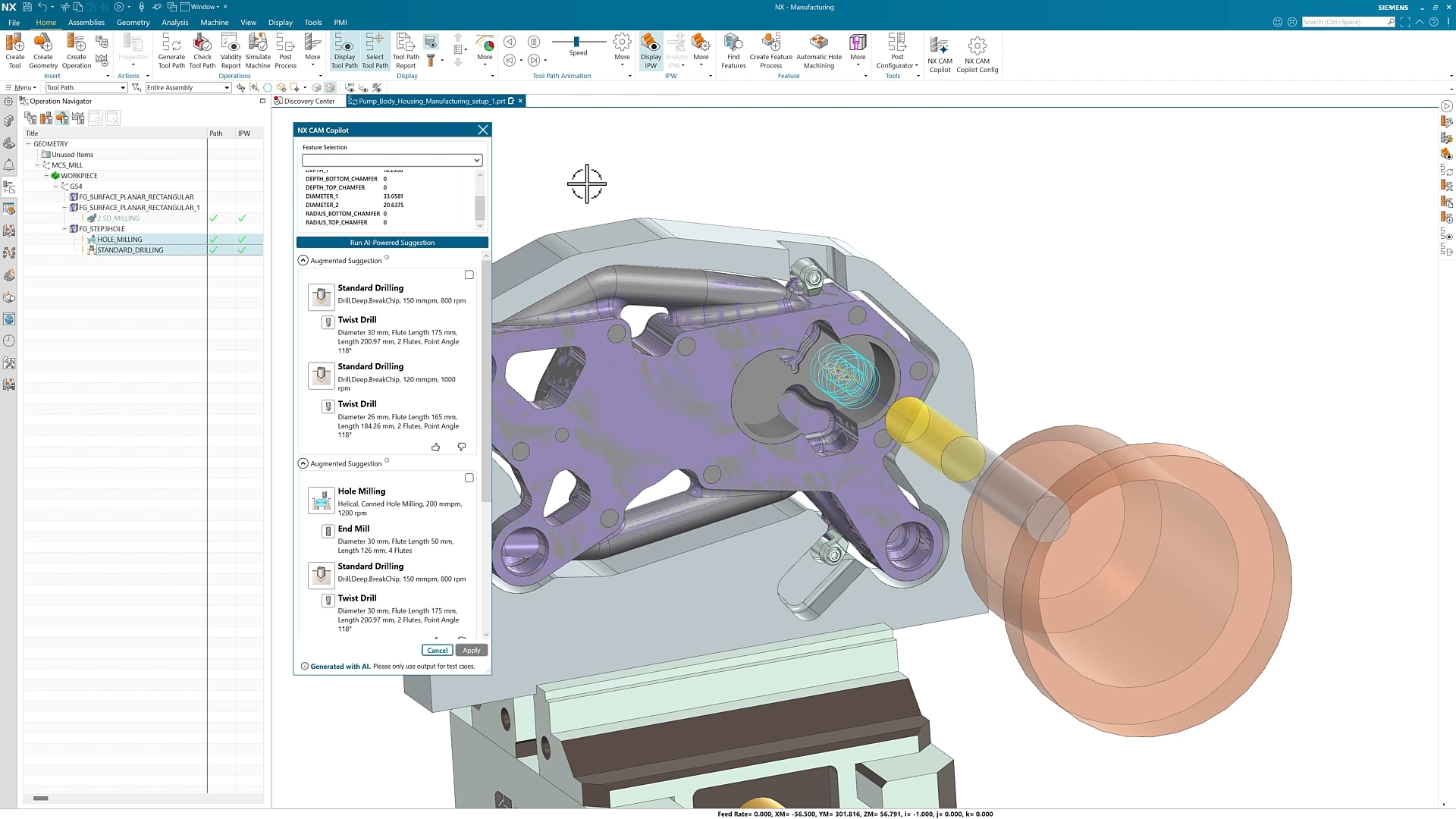

NX CAM Copilot: Elevating Programming Efficiency

As part of the discussion, Siemens’ NX CAM Copilot is featured, an AI assistant that supports programmers in creating toolpaths more quickly and accurately. By helping users navigate complex machining strategies, the Copilot reduces programming time and empowers teams to handle more work with greater confidence. Interested in exploring the NX X Manufacturing AI capabilities? Launch the free 30 day CAD/CAM trial today.

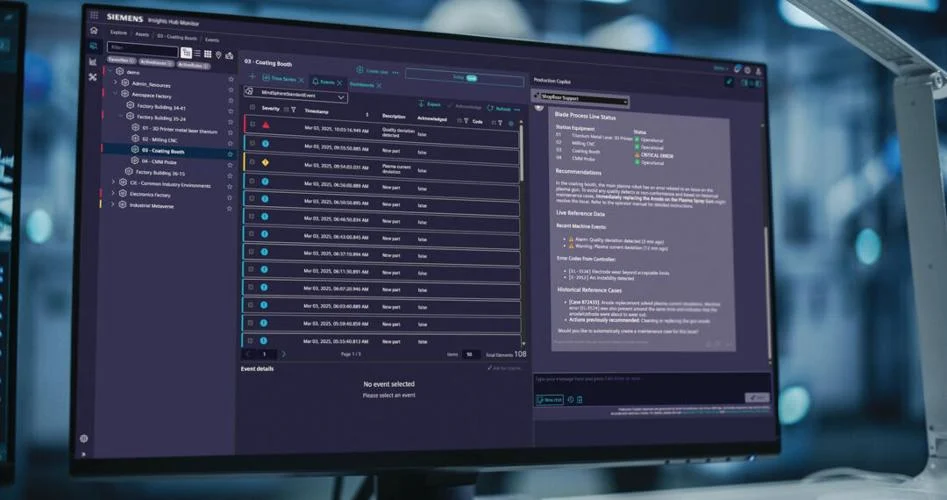

AI Production Copilot: Turning Data Into Action

One of the featured technologies I also discuss in the article is the Insights Hub Siemens AI Production Copilot, a tool designed to deeply understand each shop’s unique environment. By analyzing documentation, machine data, and real-time operations, the Copilot provides insights that help teams make better, faster decisions. From maintenance recommendations to performance optimization, it serves as a smart assistant that scales expert knowledge across the organization.

What Siemens Brings to AI in Manufacturing

In the article, I share how AI integration at Siemens Digital Industries Software delivers ROI across multiple dimensions:

- Productivity Gains: AI drives higher output per engineer and operator by automating tasks and providing intelligent assistance.

- Reduced Operational Costs: Predictive maintenance, optimized scheduling, and early quality-issue detection minimize downtime and waste.

- Faster Time-to-Market: Streamlined planning and execution, alongside accelerated training for new personnel.

- Enhanced Quality and Consistency: Reducing defects and delivering high-quality products consistently.

- Knowledge Transfer: Crucially, AI bridges the knowledge gap by effectively transferring institutional expertise to a new generation of workers.

Hence the cumulative effect is: more efficient, agile, and high-performing manufacturing operations that are both resilient and consistently deliver quality.

Leading the Shift Toward Practical AI Adoption

As manufacturers navigate increasing complexity, Siemens continues to demonstrate how AI can create meaningful, measurable progress, today, not years from now. By delivering tools that enhance human expertise, streamline operations and production, while strengthening decision-making, Siemens is helping companies build smarter, more resilient factories. With practical AI now moving from pilot projects to full-scale deployment, Siemens is not just shaping the conversation about the future of manufacturing, it’s actively enabling it.

Across the article feature, Siemens is a driving force behind practical AI adoption in manufacturing. Rather than focusing on what’s theoretically possible, Siemens demonstrates how AI can be deployed today to deliver real-world ROI, helping manufacturers work smarter, respond faster, and compete more effectively in an increasingly dynamic environment.