EOS and Siemens intensify cooperation around industrial 3D printing

Successful strategic cooperation further expanded in the areas software, automation and drive technology and AM application

EOS, the world’s leading technology supplier in the field of industrial 3D printing of metals and polymers, and Siemens continue their close collaboration to further accelerate additive manufacturing (AM) technology and application. The current cooperation includes the areas software, automation and drive technology and use of AM technology:

- Siemens control and drive components are part of the new EOS M 300 series for metal additive manufacturing

- EOS’ job and process management software EOSPRINT 2 now integrates into AM module of Siemens NX 12

- Siemens will include an EOS P 500 system for polymer industrial 3D printing into its Additive Manufacturing Experience Center in Erlangen, Germany

New EOS M 300 series includes Siemens automation and drive technology

EOS expands its portfolio of well-proven systems for metal additive manufacturing with the EOS M 300 series. The solution is an automation-ready, future-proof platform that is configurable, scalable, and secure. For this, EOS also trusts in control and drive components from the Siemens comprehensive Totally Integrated Automation (TIA) portfolio.

Alfons Eiterer, Head of System Engineering EOS, states: “EOS puts a strong focus on high quality and reliability in its new developments, while at the same time ensuring dynamical and technological progress. This is the reason we chose Siemens control technology for our new EOS M 300 series. With Siemens we can rely on proven technical components and are well prepared to handle future requirements.”

With EOS as a strategic partner in the field of industrial 3D printing Siemens has not only equipped the EOS M 300 series with components, but also the EOS P 500 system for polymer 3D printing on an industrial scale, as showcased first time at last years’ formnext fair.

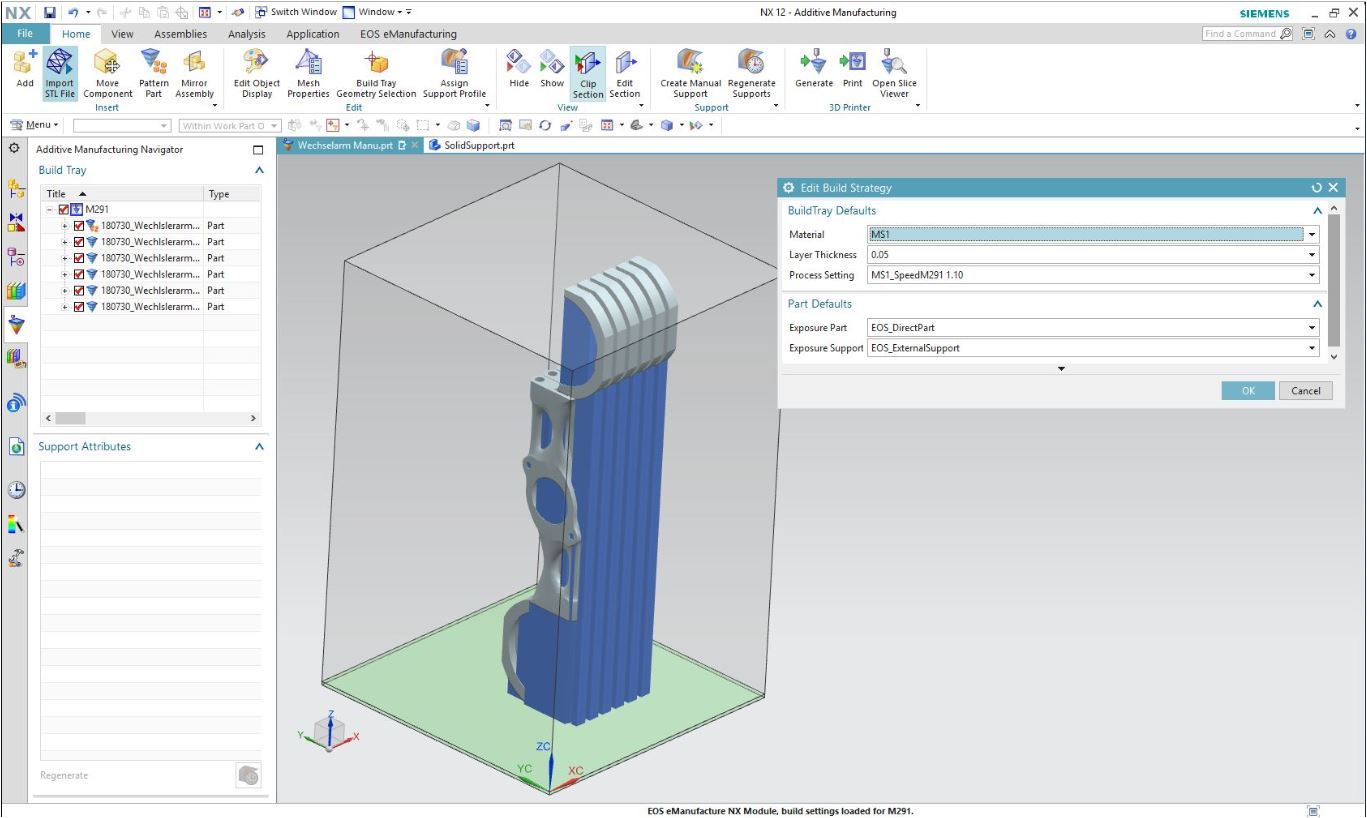

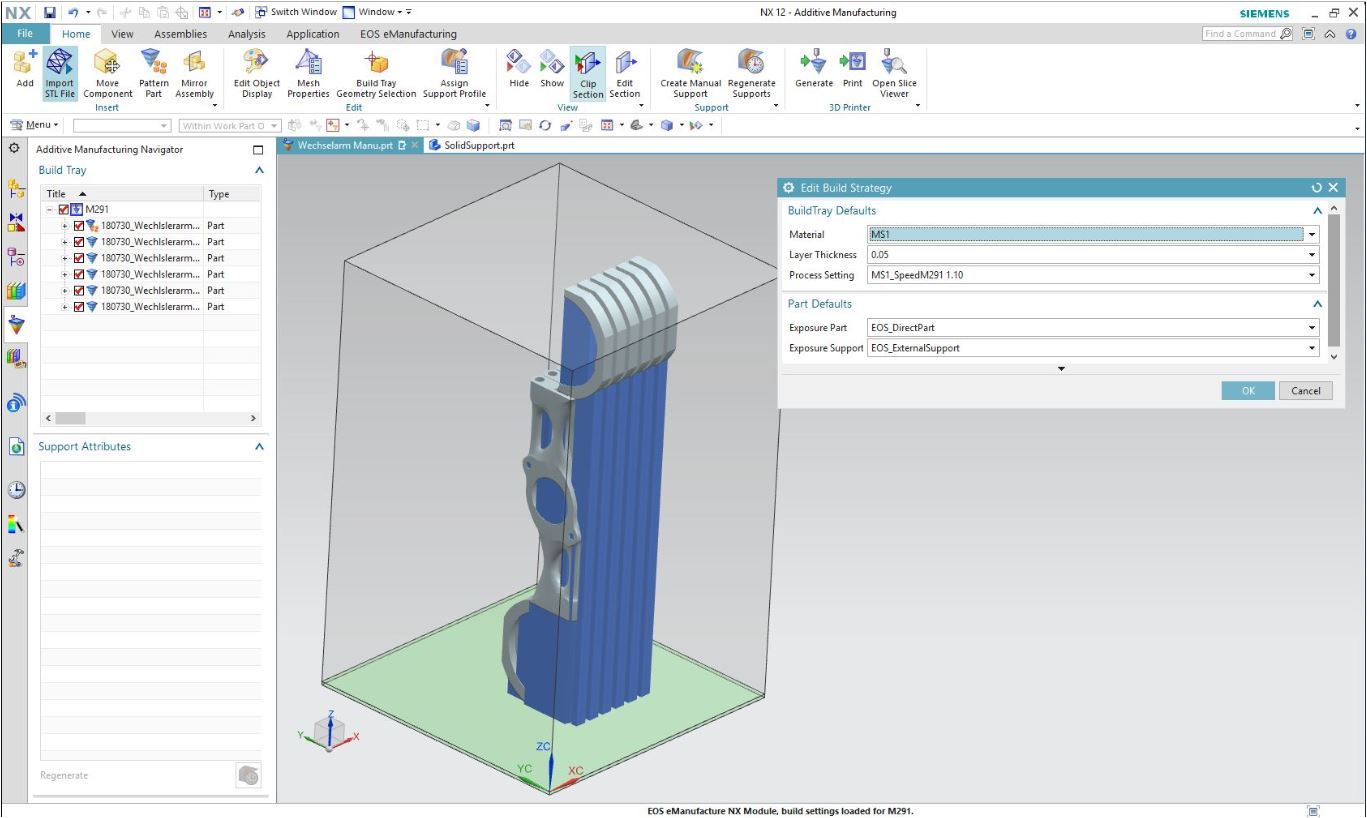

EOSPRINT driver for Siemens NX 12 integration

EOSPRINT 2 is an intuitive, open and productive CAM tool that allows businesses to optimize CAD data for EOS systems. Siemens NX 12 is a seamless end to end solution starting with design, via topology optimization and process simulation to print preparation in one user interface. Now, an EOSPRINT driver for the Siemens NX12 AM module is available. Thus, EOSPRINT 2 functions are seamlessly integrated into Siemens’ NX Fixed Plane (Powder Bed) AM software module. This integration supports Siemens overall additive manufacturing solution offering, which helps to deliver an integrated and associatively linked additive manufacturing process from design to advanced 3D printing with EOS systems. As a result, engineers benefit from a quick and uninterrupted path from product idea to 3D printed part.

EOS P 500 becomes part of Siemens Additive Manufacturing Experience Center

Siemens is going to extend its Additive Manufacturing Experience Center (AMEC) in Erlangen, Germany, with the EOS P 500 system. The AMEC provides an excellent overview and insight into different industrial AM technologies and information about the challenging industrial requirements for AM-design, -simulation and -production. It also offers an interactive experience, where the integrated seamless AM chain and the AM relevant products of Siemens are shown. “A fast industrialization of additive manufacturing can only be unleashed by a close co-operation of experts from a software, automation and drive system angle with industrial 3D printing experts, as is the case with Siemens and EOS. We are therefore proud to move with EOS into the next level of industrialization, which will help transforming additive manufacturing further from the prototyping phase into industrial serial production.”, states Dr. Karsten Heuser, VP of Additive Manufacturing at Siemens AG.

An EOSPRINT driver for the Siemens NX™ 12 AM module allows the seamless integration of EOSPRINT 2 functions into Siemens’ NX™ AM Fixed Plane (Powder Bed) module software. (Source: EOS GmbH).

An EOSPRINT driver for the Siemens NX™ 12 AM module allows the seamless integration of EOSPRINT 2 functions into Siemens’ NX™ AM Fixed Plane (Powder Bed) module software. (Source: EOS GmbH).