Additive Manufacturing Technology + Medical Industry = Innovation

A 3D printed apple a day….

One thing that was initially surprising to me when I started working with additive manufacturing is how the medical community has been one of the driving forces for additive manufacturing technology, especially on the metal printing side. We have all seen reports of 3D printed prosthetics for amputees and the like, but what I think is even more interesting is how additive manufacturing is affecting the procedures that are performed every day all day in hospitals across the world.

Your guide to a quick recovery

One thing I never considered until I started working with additive manufacturing is how it is not only end-use parts like prosthetics that benefit from customization, but also the parts that support surgical procedures. It makes a lot of sense when you think about it. During a surgery, the surgeon must make highly precise cuts. For many types of surgeries, the surgeon uses a template or guide to help position those cuts. In the past, this was done by using a set of guides of varying sizes that the surgeon selected from during surgery in a trial-and-error fashion. This process worked, but also led to the surgeon necessarily making less than optimal incisions.

Customizing surgical guides with 3D printing leads to a reduction in recovery time for the patient.

Customizing surgical guides with 3D printing leads to a reduction in recovery time for the patient.

With the ability to scan patient anatomy and to 3D print a surgical guide that conforms to the patient’s exact anatomy, the guide can be designed so that it can only be positioned in the exact right spot every time. This means that the surgeon only cuts what is necessary leading to a faster recovery time for the patient.

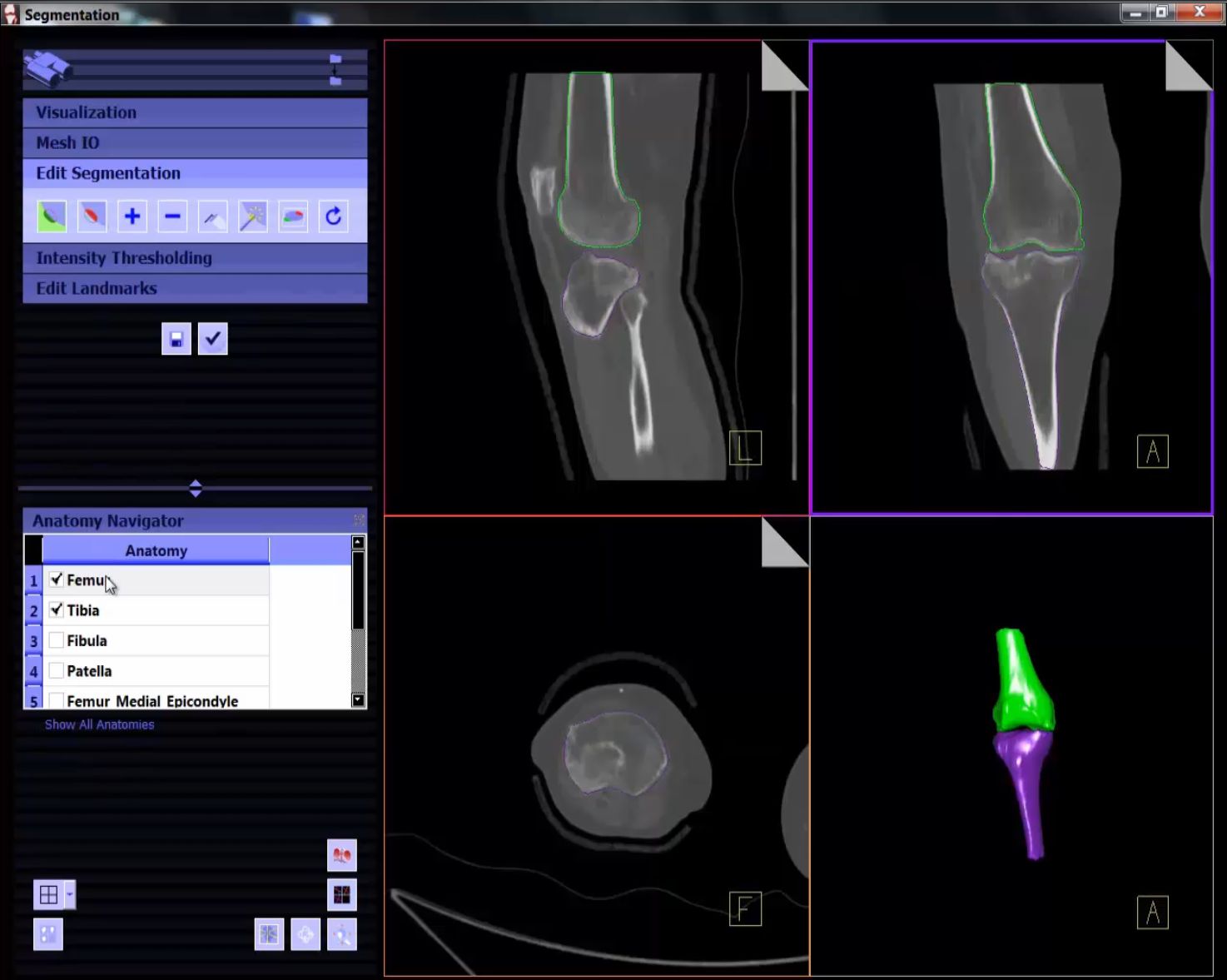

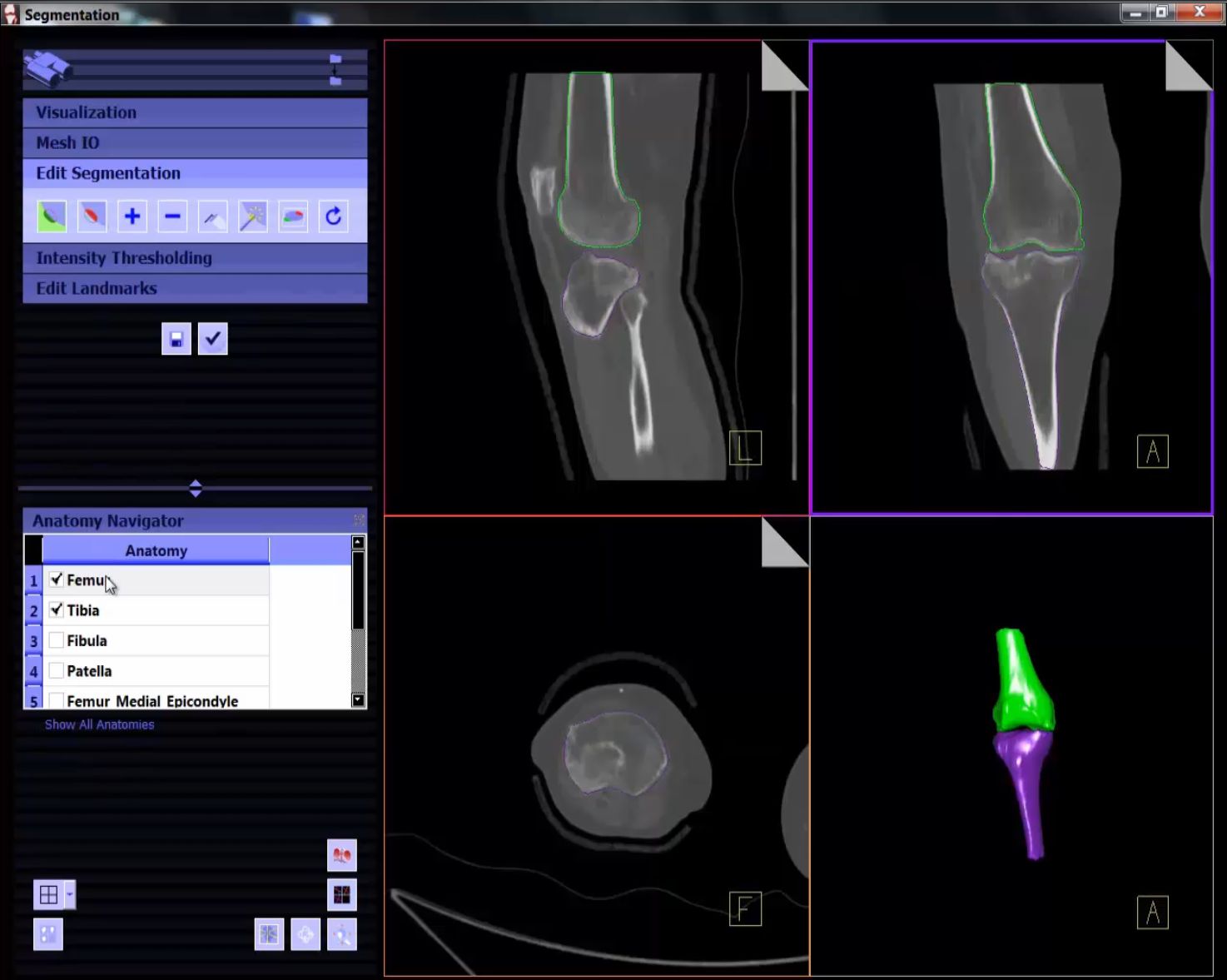

This is why in our medical demonstration we use Convergent Modeling TechnologyTM and a scan of an actual patient knee to construct a surgical guide, not the actual knee replacement. It is those surgical guides behind the scenes that are contributing to positive patient outcomes every day. We think these unsung, behind-the-scenes parts are every bit as impressive as a custom prosthetic leg.

A model patient

Another use for medical 3D printing that I had not considered was the creation of surgical models using actual patient anatomy. Of all people, surgeons know that every patient is different. While the major notes are  Scanning software can generate a 3D printed model of a patient’s anatomy that can be used to study the site before the surgery.normally the same, each of our bodies is a variation on a theme, and those differences make complex surgeries challenging.

Scanning software can generate a 3D printed model of a patient’s anatomy that can be used to study the site before the surgery.normally the same, each of our bodies is a variation on a theme, and those differences make complex surgeries challenging.

However, using 3D printing, surgeons are now able to print a model of the patient’s anatomy before the surgery allowing them to examine the surgical site in 3D. This way, they can plan the surgery before they ever touch the actual patient. They can look for those variations in patient anatomy that might pose a challenge long before they ever enter the operating room. This can be especially important for patients whose anatomy does not conform to the norm. For example patients born with unusual heart defects, or patients who have experienced trauma to an area of their body. Surgeries on such patients are never routine, and 3D printing is allowing surgeons to see what they are up against before they enter the surgical theater.

Better living through science

It has been amazing to see how the medical community has embraced additive manufacturing technology We have shown, and will continue to show, use cases from the medical industry as great examples of how 3D printing is enhancing the lives of people the world over. I, for one, cannot wait to see how the medical industry will use additive manufacturing to improve patient outcomes in the future. Better living through science, indeed.

This is part one of a five-part series on additive manufacturing technology innovation in industry.

Ashley Eckhoff has a background in engineering and has been with Siemens for over 20 years in various different capacities. He has spent the last few years deep-diving into additive manufacturing in both product design and marketing roles.