ICYMI: EMO 2025 featuring Rolls-Royce Component Reimagined Through an AI-Powered Digital Thread

As the world’s leading trade fair for manufacturing and automation technology, EMO brings together innovators, engineers, and manufacturers from around the globe to showcase the future of production. Siemens took center stage in Hanover, Germany, from September 22–26, 2025, demonstrating how advanced digital technologies are reshaping part manufacturing.

This year, Siemens presented the full power of a cross-domain digital thread, taking a Rolls-Royce jet engine sub-component, the hydraulic lubrication and scavenge pump, and helped optimize it from initial design through to production using AI, simulation, and cloud-enabled collaboration.

Watch the video to learn about the next-gen aerospace demonstration.

In modern part manufacturing, a key challenge is ensuring that complex machining operations are executed accurately and efficiently, without costly trial-and-error on the shopfloor. Part manufacturers face increasing pressure to reduce setup times, prevent machining collisions, and maximize machine uptime and throughput. Achieving these goals requires not only precision and expertise but also powerful digital manufacturing software that can anticipate issues, automate repetitive tasks, and help teams make better decisions faster.

At EMO 2025, Siemens demonstrated exactly how this is possible. By leveraging a fully connected digital thread powered by AI and simulation, Siemens and Rolls-Royce achieved a remarkable transformation that made the jet engine subcomponent 32% lighter, 15% lower fatigue stress and production-ready. A clear demonstration of how next-generation aerospace performance, sustainability, and manufacturability can be achieved through intelligent, cloud-enabled engineering.

Spotlight on NX CAM: where AI understands the language of engineering

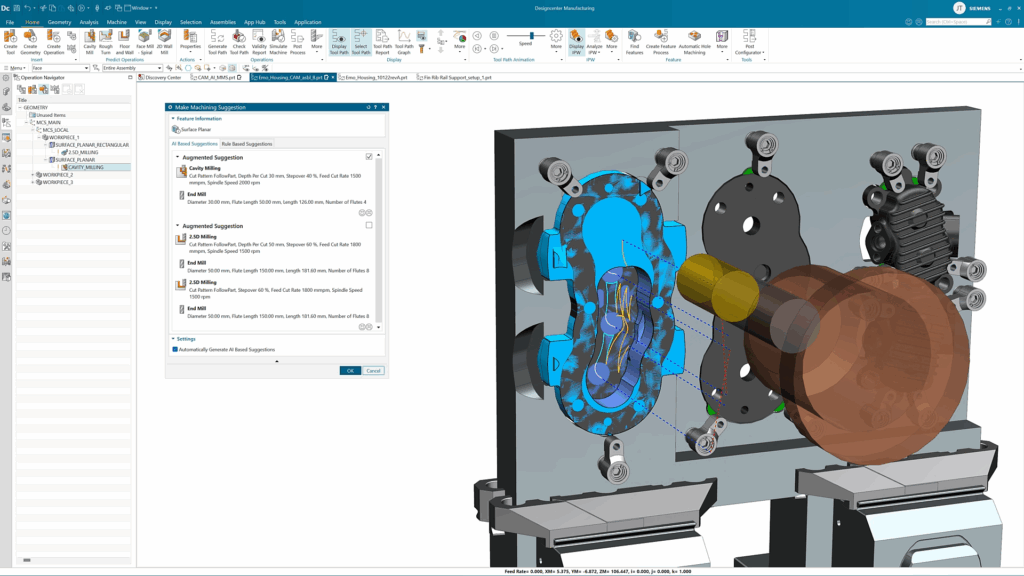

NX CAM, now equipped with the AI-powered Co-Pilot, enters the digitalization storyline. Instead of manually setting up every toolpath, engineers can simply select a feature, and the Co-Pilot offers intelligent machining suggestions, such as cutting depth, tool choice, and even strategies to speed up cycle times. Interesting in trying it yourself? Get access to NX CAM AI Copilot through the free NX CAD/CAM trial.

The NX CAM Copilot can help automate programming of complex parts through intelligent, geometry-based machining strategies. These capabilities enable manufacturers to reduce programming time by up to 80%, helping boost productivity, consistency, and throughput.

Looking ahead: transform your part manufacturing

Whether you missed the event or want to explore the AI-powered NX CAM Co-Pilot further, now is the ideal time to discover how Siemens is redefining part manufacturing as demonstrated at EMO 2025. Unlock next-level productivity with NX X Manufacturing, your cloud-powered, AI-enhanced, end-to-end part manufacturing solution.