Thinking big with NX software

This blog post and video below were provided by Eric Magray, the President of Avant Manufacturing, Portland, Oregon.

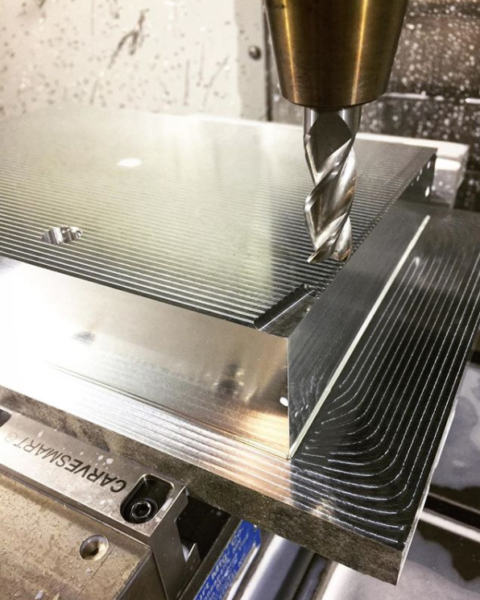

Avant Manufacturing is a small manufacturing company with big ambitions. Avant is currently a one-machine, one-man, one-dog operation, which was founded in late 2015. CNC milling is the main service currently offered, with a focus on efficiently producing high-quality aluminum components in both prototype and production quantities. I’d like to tell you about why I chose Siemens NX software for Avant.

A new way of making parts

During my previous years in the CNC machining business, I have thought non-stop about ways in which things could work better, more efficiently, and more reliably. I admit that in addition to being a mechanical nerd, I am a bit of a computer nerd. Understanding the power of modern computers and the importance of manufacturing data, I kept coming back to the idea that CAD and CAM should have a very tight integration.

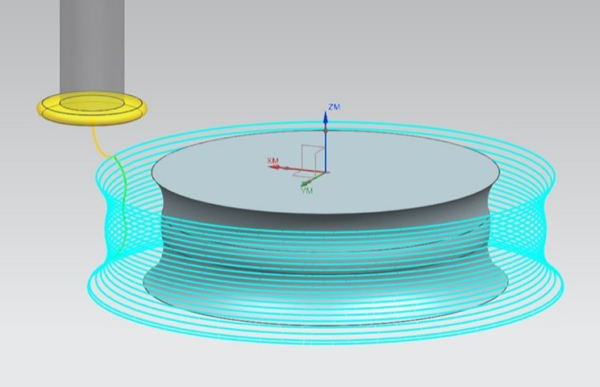

Since manufacturing is so much a science, there should be no reason why we cannot plan and optimize entire manufacturing processes at the click of a button. Robust digital record keeping is necessary to achieve that, and doing a little research led me to PDM and PLM. Then I learned about CAE tools, and my first thought was how to apply them in the process planning and programming to successfully machine parts on CNC equipment. It became clear that CAE integration into the CAD/CAM stack would be extremely valuable. The idea of CAD, CAM, CAE, PDM, and PLM all working together like a well-oiled gearbox, really gets me excited.

Virtual factory becomes a reality

You see, I am very passionate about manufacturing and automation. I have put much effort in over the years conceptualizing what I now consider a virtual factory. Details including complete digital models of machine tools, modular work-holding, tool-holding, robotic automation, effectors, shop layout, connected devices, server operating systems, network configuration, scripts, rules, g-code verification, change order processes, material receiving, shipping, accounting, and more are all stored in my mind. I am also starting to understand how artificial intelligence (AI) and neural networks capabilities will impact manufacturing. It’s exciting to see how my virtual factory idea is slowly turning into a reality as the business grows.

Expanding the small operation

Many have asked, “You are running a small job-shop, why purchase such advanced software (when a simpler one will do)?” And if I were thinking from the small job-shop perspective, I may have asked myself the same question. But when I look from the perspective of operating the shop which I intend to create, there honestly wasn’t much of a choice. To do the things I intend to do while keeping as unified a system as possible, NX appeared to be the best option. Sure, my shop is very small at the moment (though I am a bit proud of the amount and quality of the work produced with such little resources), but it’s growing rapidly. Soon, I hope Avant will be more than a one-machine, one-man, one-dog operation. It will be the shop I have imagined for so many years, mass producing high quality components very efficiently, cost effectively, profitably, and on time for happy customers (likely with a few more dogs). At that point looking back, I can see the decision to purchase NX software will have been one of the keys which helped me to unlock my dream.

To help you better understand why I choose to use NX CAM, I’ve created this video from my shop in Portland, Oregon. Take a look and let me know what you think in the comments section below.