Blog Series: The value of NX for part manufacturers

The Value of NX for Part Manufacturers – NX CAM software functions intrinsically tied to the NX model geometry and toolpath information.

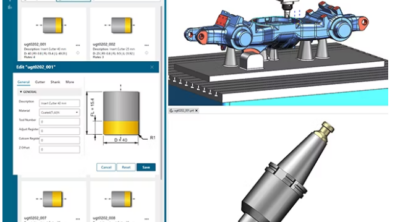

In my previous blog, “The Value of NX for Part Manufacturers – One Integrated System,” I touched on the value of NX based on its evolution, from the earliest versions, as a fully integrated CAD/CAM system. “All in NX” is a phrase we put on some presentation material when we point to value users get from working in one seamless environment. Today not only can the NX CAM software userhave access to a full range of the latest and greatest CAD functions, but NX now offers CMM programming, robot programming, dedicated mold and die tooling design and a host of supporting functions.

When we dig deeper we see much more inside NX that adds value for the part manufacturing engineering user. We take for granted that the machining operations created using NX CAM software functions are intrinsically tied to the NX model geometry. You might expect this to be the case with all systems. In NX it means that any change to the underlying model geometry will show up as flags where a toolpath is now “out of date” but as you would expect a simple regeneration function and the path is normally fixed. Taking this a step further, we don’t want to spend time recalculating paths or non-cutting moves that aren’t affected by a geometry change – that would waste precious programming time. NX can selectively update as needed.

Not all users need to regenerate their toolpaths when geometry changes take place. We continue to add toolpath editing functions to allow the user to make quick adjustments to get the desired output as quickly as possible. This is a practice that’s fine in some industries where it’s acceptable to introduce a degree of separation between model and the CNC output if that’s the faster way to get the job to the shop.

Often as Siemens CAD/CAM developers we focus on adding or updating major capabilities. More recently, enabled by our move to an AGILE development process, we have elevated the level of attention paid to a range of much smaller, but amazingly useful enhancements. A great example is in the area of toolpath display. We have a huge amount of information inside the system that, when key elements can be shown, provides real help to the programmer who wants to see what’s happening along a path. This tool angle, could be a precise display of where there might be issues on a path. These can be simple projects to develop and the value to the programmer can be great.

In a separate blog, I will add detail on the benefits we get from an AGILE software development process with some more examples of recent developments in the world of part manufacturing.

There are many more reasons why NX is a platform of choice for so many part manufacturers. I will provide some further examples in the next blog in the “Value of NX for Part Manufacturers” series.