NX | Tips & Tricks | Molded Part Designer

Molded Part Design is an NX™ software add-on module that provides a dedicated workspace for the development of injection-molded plastic parts.

The June 2024 release of NX brought a range of enhancements, including AI-enabled automation for the Moldability Validation and Feature Validation commands.

Watch the video below to see some handy hints for getting the most from Molded Part Designer’s latest updates, or keep scrolling if you’d prefer to read.

Molded Part Design workflow

Before we get to the exciting new validation enhancements, we first need something to validate!

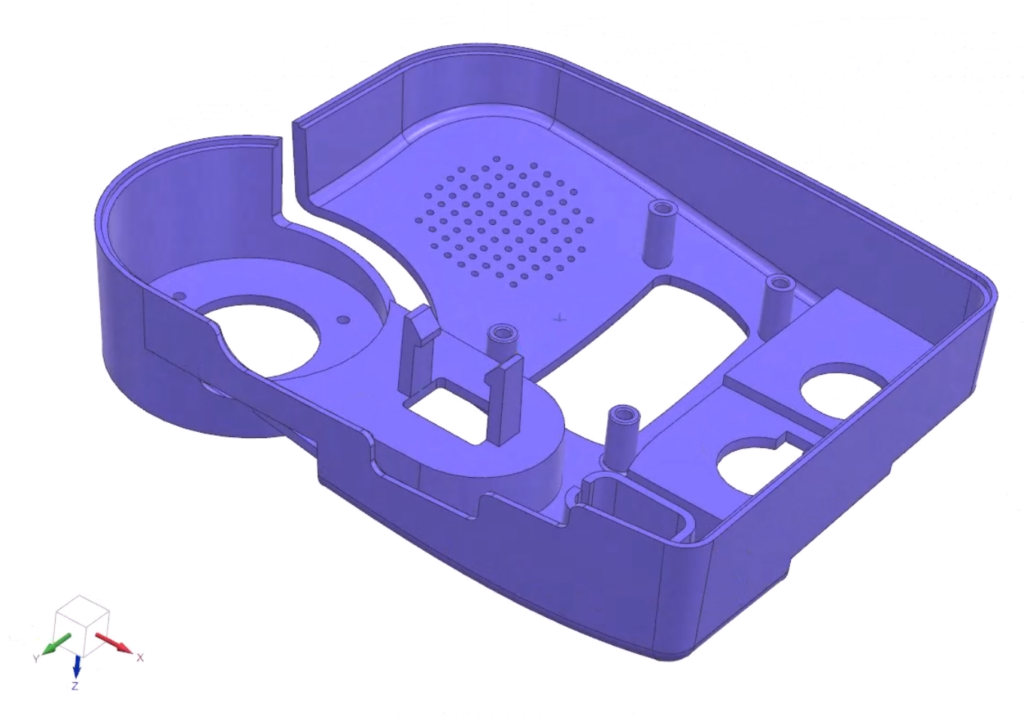

In the video, Scott demonstrates how quick and easy it is to add standard molded part features such as mounting bosses, snap joints, ribs and grooves to a design.

You can place them on a model and customize the geometry with a few clicks, no need to manually model them from scratch.

Helpful legends show you which options correspond to which aspect of the geometry.

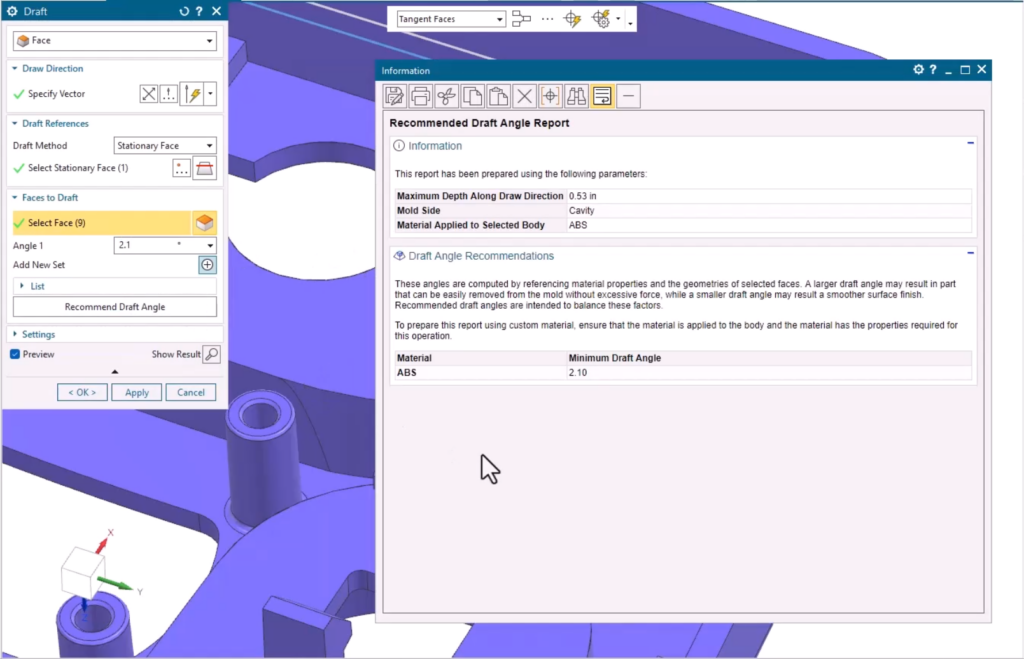

Adding draft to the faces of injection-molded parts is vital for manufacturability.

Molded Part Design automatically calculates a recommended draft angle based on the geometry selected and the material assigned to the part.

Moldability and Feature Validation

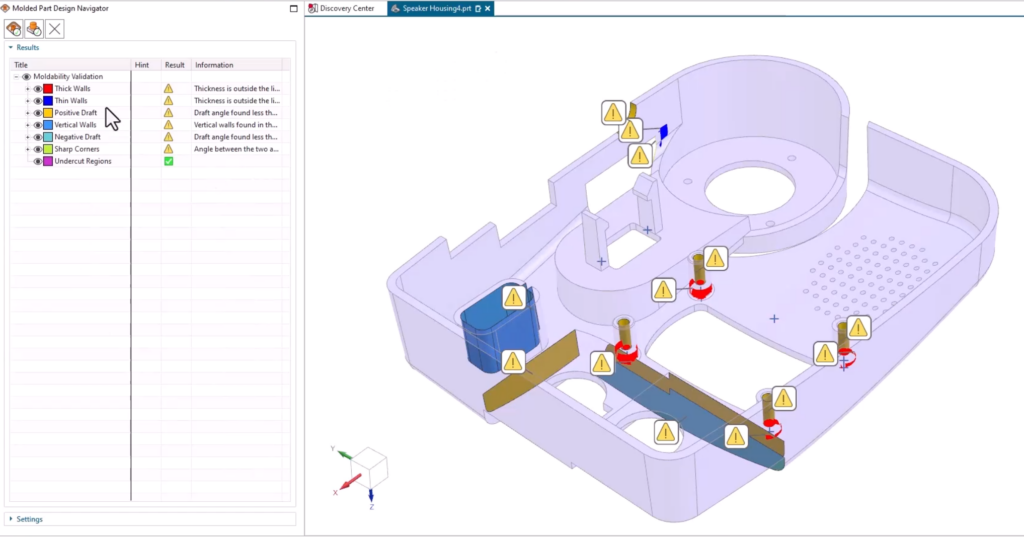

The Moldability Validation and Feature Validation commands analyze your design and highlight potential issues to help you comply with industry best practices for injection-molded manufacturing.

Moldability Validation looks for common issues such as walls that are too thick or too thin, or faces with insufficient draft. It highlights areas of your design that fail validation and gives warnings for edge cases for you to check manually.

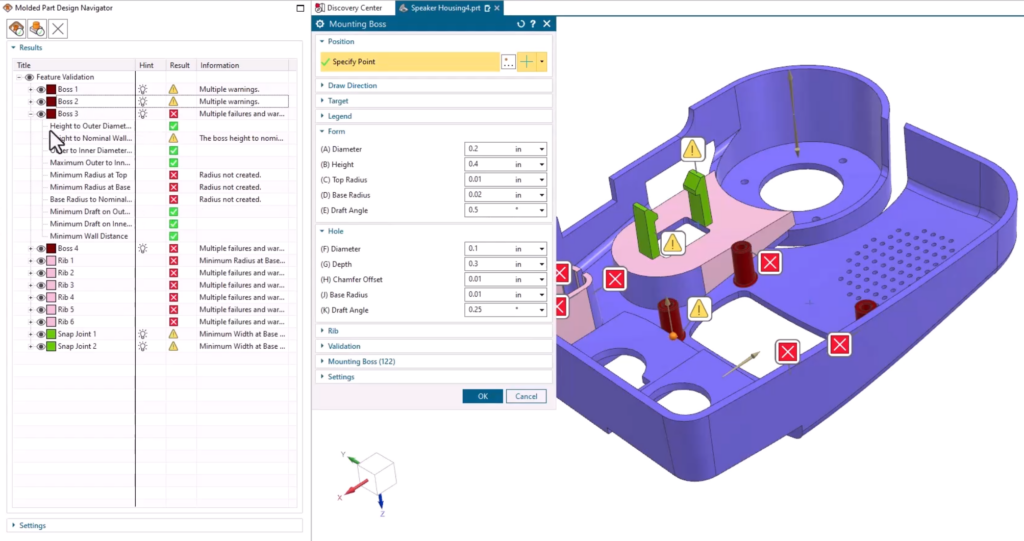

Feature Validation automatically recognizes features specific to Molded Part Design, such as snap joints, bosses and ribs.

It then provides a comprehensive review of the geometry and explains any issues that it finds in the Molded Part Navigator.

Validation Enhancements

New for June 2024 is the Hint column that shows in the Molded Part Design Navigator for both Moldability Validation and Feature Validation.

When a lightbulb icon shows here, NX will provide an AI-powered suggestion for how to resolve the related issue. Just hover your mouse over the lightbulb icon to see the hint.

When you right-click a failed validation result, NX will display one of four options depending on the context so you can quickly resolve the issue – Edit, Draft, Edge Blend or Resize Blend.

You can now also…

- Exclude certain features from Feature Validation from the Molded Part Design Preferences dialog

- See the values that NX has calculated during the Feature Validation operation if you right-click a validation result and choose Show Result Info

Once validation is complete and you’ve resolved any issues, the part is ready for manufacture!

Outro

Like many other NX add-on modules, Molded Part Design is available through value-based licensing.

Value-based licensing is a flexible, scalable and affordable way to add specialized and advanced capabilities to the core NX Design experience.

If you’re already using value-based licensing, you can access Molded Part Design today using tokens from your token pool.

Read more about value-based licensing if you’d like to get started.