From concept to comfort | A Siemens Xcelerator story with Polipol

We’re happy to announce that Polipol have adopted several products from the Siemens Xcelerator portfolio as part of their digital transformation. New tools available to Polipol means they are in prime position to re-think their development process from concept, through production and the customer experience.

What’s more, Polipol are ready to change their production methods by combining traditional craftsmanship with technologies for the future.

Who are Polipol?

Polipol are a leading European upholstered furniture company based in Germany. Founded in 1990, the company consists of 8000 employees across 9 international locations, turning over more than 500 million in annual sales.

A differentiator for Polipol is their products are rooted in traditional craftsmanship; it’s about creating products with emotion. Whether that is their distinct sofa range, eye-catching beds, or unique armchairs, the goal is to create products with real comfort and identity.

Why are the embarking on a digital transformation journey?

Change always comes from identifying a key challenge. For Polipol, they recognized that customer demands were creating additional product complexities, whilst cross-location collaboration was also impacting productivity.

The turning point was a realization that tradition and craftsmanship alone is not enough in today’s’ fast-paced market. As a result, it was apparent that a digital shift was required, with a need for smarter collaboration and faster development times.

Managing a diverse product portfolio with Designcenter NX and Teamcenter

Polipol’s creative journey for new products begins in Designcenter NX™ software. Every part, product, frame, form, fabric and fitting is digitally represented down to the smallest detail using a range of tools within Designcenter NX. But it doesn’t stop there; these models are enriched in Teamcenter® software with product requirements, material definitions and metadata, ready for downstream consumption.

The importance of Immersive Engineering

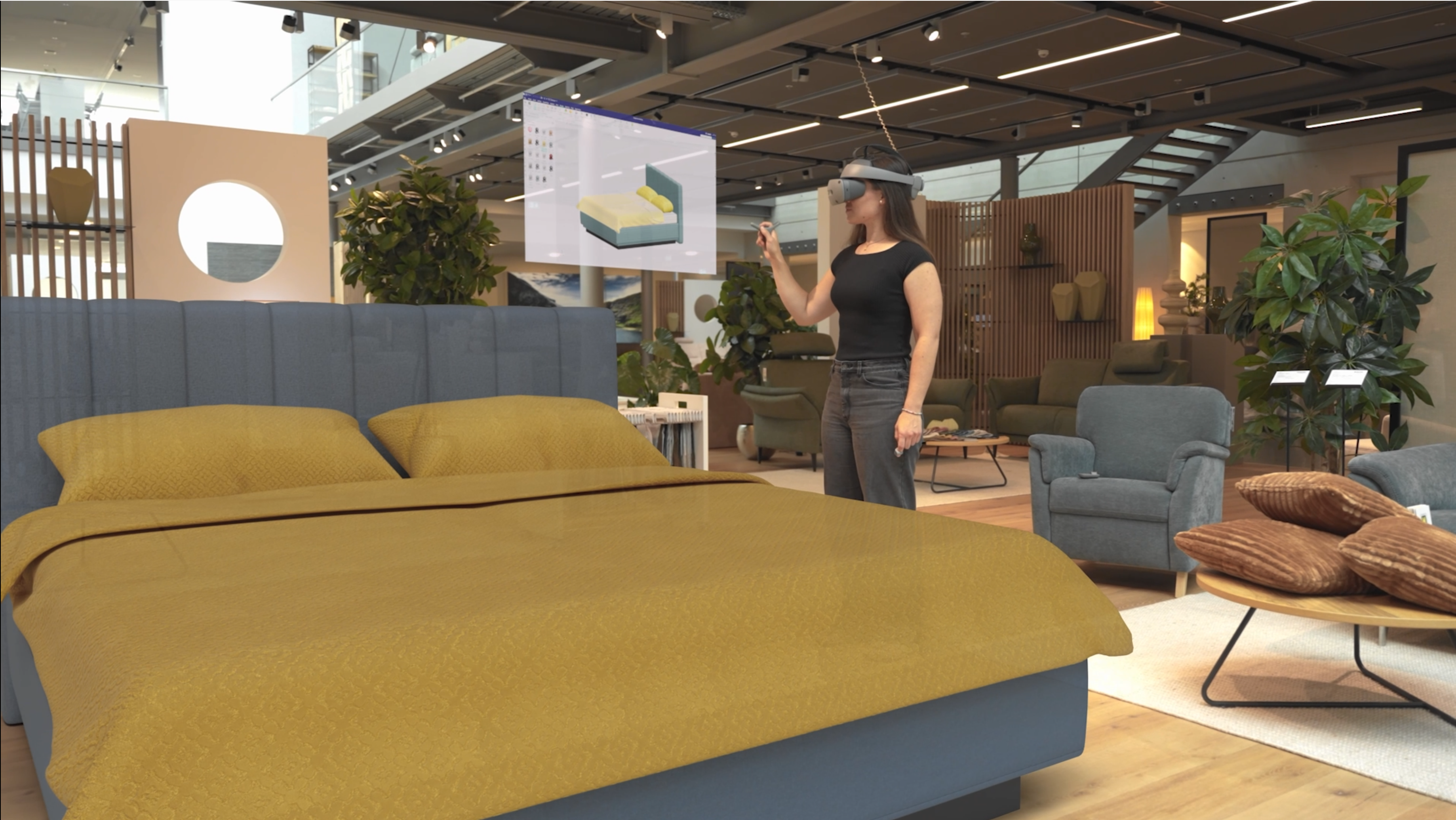

At the heart of the digital shift for Polipol is Immersive Engineering, creating an environment allowing for photo-realistic interaction with their extensive product portfolio. Using immersive designer in the Sony head-mounted display (HMD) is allowing all members of the design process to explore proportions, materials and textures visible, making the ‘soul of their products visible even before they are physically built.

From the moment I used Immersive Engineering, I found it to be very intuitive. I’m not working with my mouse and keyboard; I now have the opportunity to create the furniture with my hands

Sophia Schnute, CAD Developer Polipol

And the result?

Combining these Siemens Xcelerator tools is preparing Polipol for the future by creating a ‘central source of truth’. Metadata for all 500+ products in Polipols portfolio are mainained in a singular environment.

Additionally, tangible benefits include the ability to save on development costs per model, greater control over design change iterations and ultimately, development time for models being drastically cut. It’s a digital workflow for the future, enabling better transparency of work and high data quality from the start of the production process.