A Win for the Mold Tool & Die Industry | Success Story

This story comes to us from our partners at Longterm Technology Services, which is a technology-based company in London, involving a three-way partnership between St. Clair College, Longterm Technology Services Inc. and the Mold Making Industry.

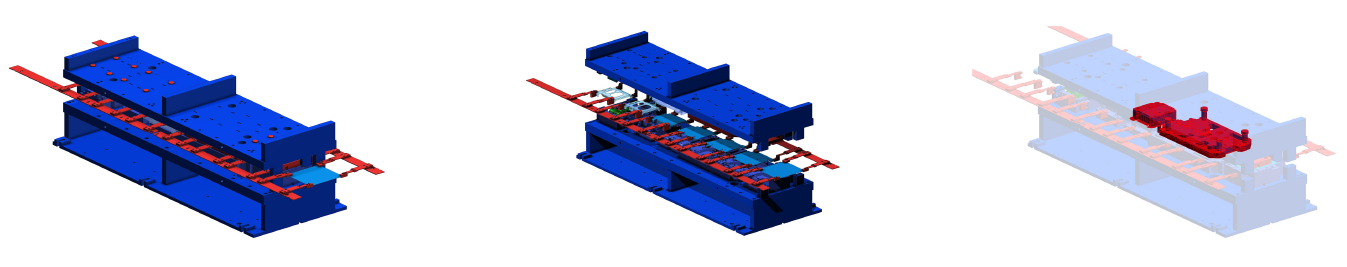

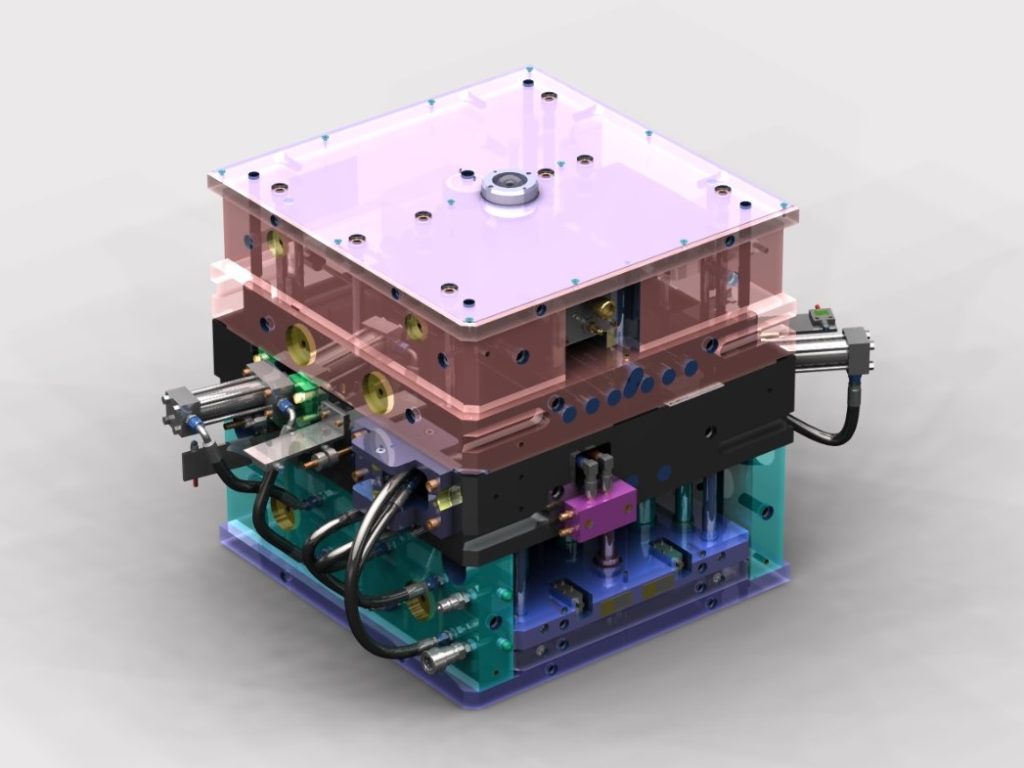

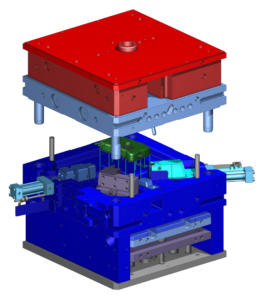

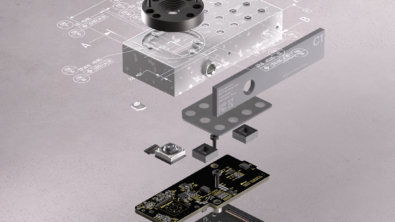

The project involved computer-aided design (CAD) models, which are used in the mold industry in order to design and visualize parts prior to manufacturing.

CAD software is a powerful tool that can mitigate start-up risks by troubleshooting potential flaws before building the physical part. But because molds are complex with many moving parts, the mold industry is often faced with challenges.

Longterm Technology Services Inc. has addressed these challenges by developing motion simulation software, called DYNMIK, which allows the user to simulate the motions of the moving parts. The solution works within the Siemens NX environment. This allows the designer to detect conditions in which parts may collide or what are known as crash conditions.

However, adoption of any new software can be a challenge, and Longterm, understanding this, enlisted the help of the St. Clair College Research and Development (R & D) department, along with a couple of mold companies, which showed interest in this software. The companies provided the college with several CAD files to test and after Longterm provided the training to the St. Clair College research team, consisting of faculty and students, they were ready to deploy the files into DYNMIK.

The results of this collaboration have been a resounding success, as the simulations have provided valuable data to mitigate potential launch issues. This alliance was initiated by the involvement of members from the Canadian Association of Mold Makers (CAMM) organization.

Redoe Mold had been looking to improve quality by reducing the incident rate of crash conditions due to unforeseen design flaws, according to Demi Priestyeski, of Redoe Mold.

Redoe supplied several complex mold designs to St. Clair College for evaluation over a period of 18 months. The college appointed one or two technical students for the duration, to apply DYNMIK software to simulate and test mold tool operation.

This in turn provided valuable hands-on experience for the students interested in designing for the automotive industry.

In several instances, the software exposed minor crash conditions early enough in the tool build process to modify the designs and adjust the steel prior to tool tryout, thereby saving the cost of subsequent corrections.

Redoe Mold has since purchased DYNMIK from Longterm Technology Services Inc. for current tool design and builds to improve quality.

Providing value to the customer and advanced educational opportunities for students is the ultimate goal of conducting research projects with industry partners, said Peter Wawrow, Director of Applied R & D at St. Clair College.

Steven Lenardon, president of Arlen Tools, said the opportunity to work with St. Clair College and the Siemens NX based Longterm Technology Services Inc.’s DYNMIK Design software has been a positive experience.

“It has allowed us to verify some complex tooling solutions in the design phase rather than at assembly and testing.”

From the College’s perspective, this project has provided students with advanced educational opportunities, as they worked closely with industry partners on real-world projects. According to Linsey Kerkhove, R&D Program Manager at the college, “the research students were genuinely excited to work on these projects and they thrived in that environment.”

The college’s role is to prepare students for the work environment.

“R & D projects not only accelerate the learning curve so that on the job training is decreased, these projects also educate the workforce of the future,” Wawrow said.

Aaron Guo, president of Longterm Technology Services Inc., described the collaboration as a success story. “We are glad to be a part of this achievement. Collaborations between technology colleges and tooling organizations provide invaluable experience to students, who will be the leaders of tomorrow. I always look forward to the opportunities that inspire tomorrow. Longterm Technology Services Inc. will keep supporting St. Clair students in this research initiative because the institution has shown remarkable performance.”

The Mold – Motion Simulation Research project has continually exceeded expectations by increasing more job and research opportunities for St. Clair College students, as students who have worked on the project are sought by the industry partners.

“Collaboration and partnerships are the foundation for success within the Canadian Association of Mold Makers (CAMM),” says Mike Bilton, chair of CAMM. “We believe in embracing and deploying the latest technology in an increasingly digital world, and strongly urge both members and non-members to stay abreast of the technology curve as much as possible.

“Adoption of new software can be a challenge, but working together with industry, education and government results in victories just like this,” Bilton added.

“We are excited to continue to build on these relationships because together we do what we do best and can serve our local and regional small to medium enterprises.” Job prospects for St. Clair College students have increased remarkably after students’ involvement in the Mold – Motion Simulation project, a good reason for Longterm Technology Services Inc., St. Clair College, and mold companies to continue their successful collaboration

Comments

Leave a Reply

You must be logged in to post a comment.

Its nice case study, we need PDF Doc for the same